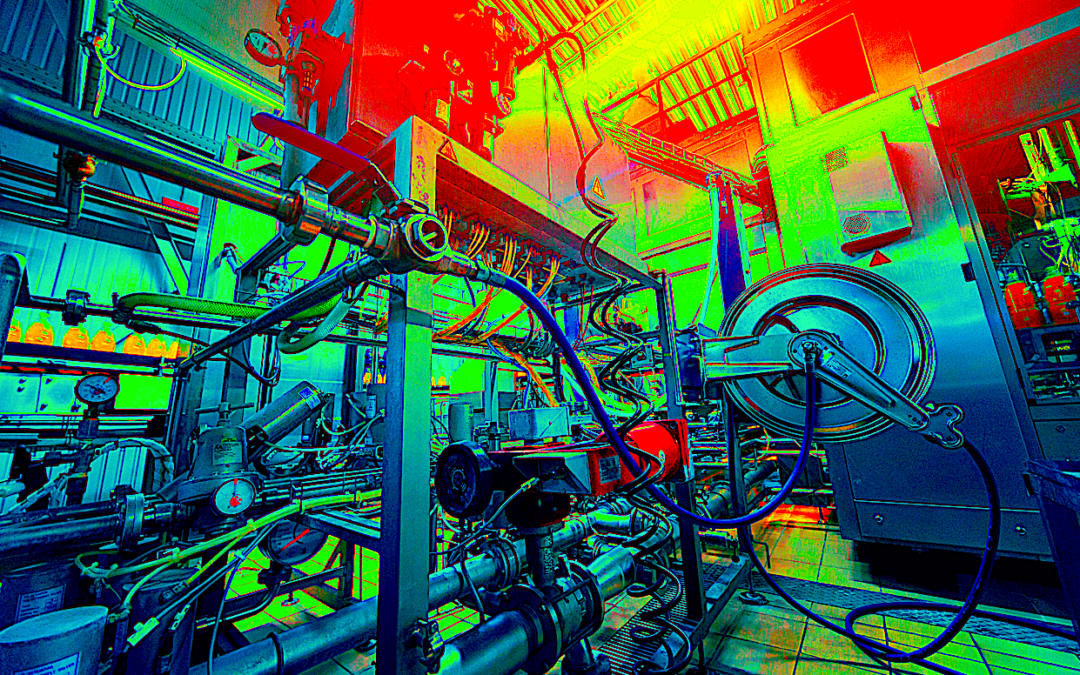

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Oct 17, 2020 | Asset Management, RAM Tools & Methods

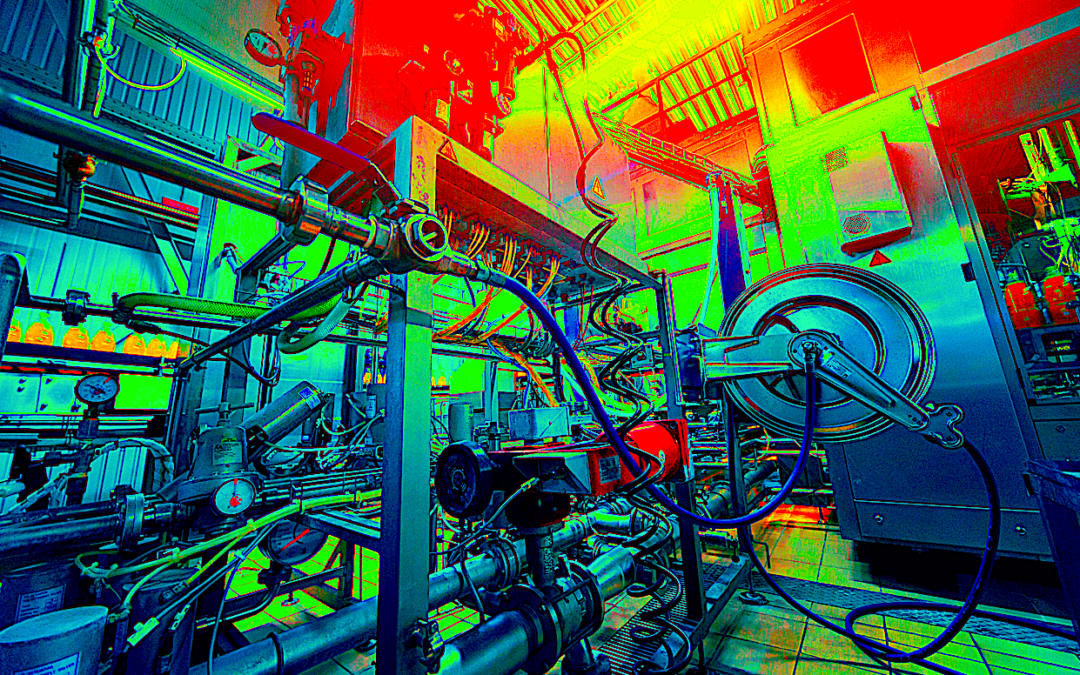

The concept of stress vs. strength “interference” is important in the field of reliability engineering. This concept is so simple that one could almost call it naïve. However, minimizing interference between stress and strength in the plant often results in a clash...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 12, 2020 | Asset Management

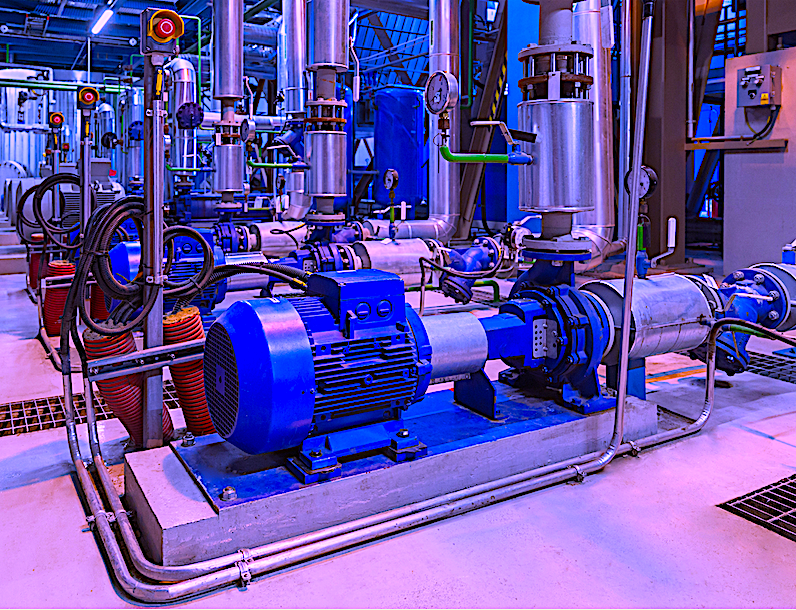

As an asset-management consultant for the last 30+ plus years, I’ve never encountered the perfect asset-management system. Organizations can, and do, achieve perfection for a short while, but perfection is a moving target that’s often thwarted by...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Sep 25, 2020 | Asset Management, Planning & Scheduling

As the American singer/songwriter Jimmy Buffett observed, “Without geography, you are nowhere!” Making sense of any production or maintenance workflow, process or procedure requires a textual map in the form of a diagram, visual representation, or an ordered text list...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Sep 20, 2020 | Asset Management, Newsletter Column, Plant Operations

Those who have attended one of my workshops on various aspects of reliability engineering and management, or have seen me present at conferences, may have heard me say, “Data is the difference between deciding and guessing.” It’s a slogan I’ve used for at...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Sep 18, 2020 | Asset Management, Planning & Scheduling

When a maintenance-work request reaches the desk of the planner, his or her first action item is to review the request and determine the priority of the work. This determination will influence whether the planner takes immediate action (Emergency Response) or queues...

by Tim Dunton, CMRP, CMRT | Sep 16, 2020 | Asset Management, RAM Tools & Methods

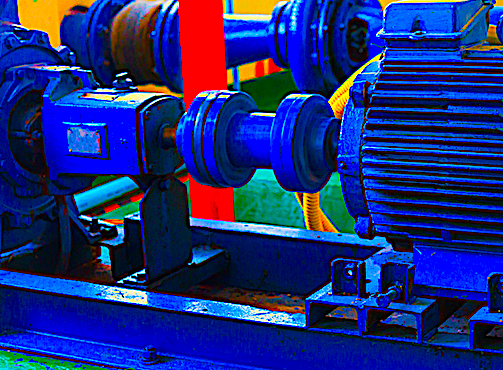

In a recent article (Aug. 28, 2020), we focused on the importance of correcting soft foot on the machines in our plants and facilities. Here, we focus on the proper ways to check for and eliminate it. As we discussed previously, soft foot is the condition that exists...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Sep 6, 2020 | Asset Management, Newsletter Column

Those of us working in the world of manufacturing and facilities management are frequently called upon to find ways of improving maintenance. But maintenance-improvement practices come in many different forms. What are maintenance best practices? What’s under the...

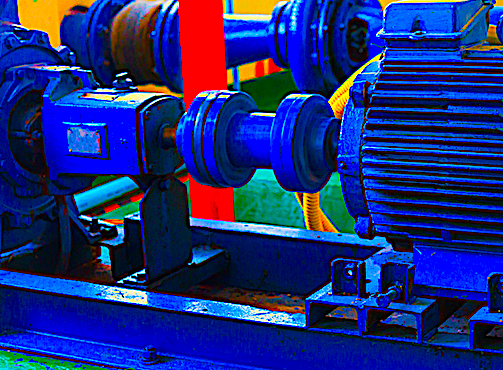

by Tim Dunton, CMRP, CMRT | Aug 28, 2020 | Asset Management, RAM Tools & Methods

Cursory soft-foot checks are often performed as means of “checking the box” at the start of an alignment process. If, however, we are to eradicate soft foot from the industrial landscape, these checks need to become an integral part of the alignment process and be...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Aug 23, 2020 | Asset Management, Newsletter Column

We live in an overly complex world with complex tools and programs to keep equipment and technology up and running. When we find ourselves up to our belt loops in perplexing reliability issues, we have an opportunity (make that ‘an obligation’) to learn...

by Tim Dunton, CMRP, CMRT | Aug 20, 2020 | Asset Management, RAM Tools & Methods

In last week’s article for The RAM Review (August 14, 2020), we discussed some of the tools needed to implement precision maintenance. This week we focus on what is, perhaps, one of the most important tools. Documenting results and what was done on a job is crucial in...