by Ken Bannister, MEch (UK), CMRP, MLE, Editor | May 2, 2020 | Asset Management, RAM Tools & Methods

During a recent COVID-19-compelled social-distancing phone call with a colleague, our discussion turned to the topic of asset-management practices and their overall effect on equipment care and the maintenance workforce. My colleague then challenged me to identify the...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Apr 25, 2020 | Planning & Scheduling, RAM Tools & Methods

In the world of maintenance and asset management, equipment failure is an all too common occurrence. Unfortunately, setting in place a strategy and methodology to understand and learn from each equipment failure is not a common occurrence. It’s through an acute...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Apr 18, 2020 | Asset Management, Planning & Scheduling

Have you ever wondered what decision-making process drove previous maintenance administrations to set up your site’s asset-management program in the way that it currently runs? Program architects, in all realms of business, are notorious for poorly documenting...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Apr 10, 2020 | Planning & Scheduling, RAM Tools & Methods

A maintenance work order is developed in two distinctive stages. Stage One involves receiving, understanding, and accepting the “ask” or request for work from the maintenance client or stakeholder. This is commonly called a Maintenance Work Request (or MWR). Stage Two...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Mar 29, 2020 | Newsletter Column, Workforce Issues

The year was 1859. That’s when Charles Dickens released his 13th novel to the public. Widely regarded as a masterpiece of fiction, A Tale of Two Cities opens with what is, arguably, the most famous opening line in English literature: “It was the best of times, it was...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Mar 20, 2020 | Maintenance Management, RAM Tools & Methods

The global pandemic we’re now facing has put all of us, individuals and businesses alike, on an emergency footing. COVID-19 has already closed down or seriously affected the operation of most public facilities, and is likely to bring much of industry to a severe...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Mar 7, 2020 | Maintenance Management, RAM's Human Factor

As an asset-management consultant working with a new client, one of my first steps is to perform a Maintenance Operation Effectiveness Review (MOER) in which we review and quantify the current state of the maintenance organization to determine how effectively it...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Feb 27, 2020 | Asset Management, The Sustainable Plant

This fourth and final “Fingerprint to Footprint” series installment focuses on the collaboration between the maintenance and operations groups to understand and map out how each equipment piece, manufacturing-process line, and vehicle is operated on a day-to-day basis...

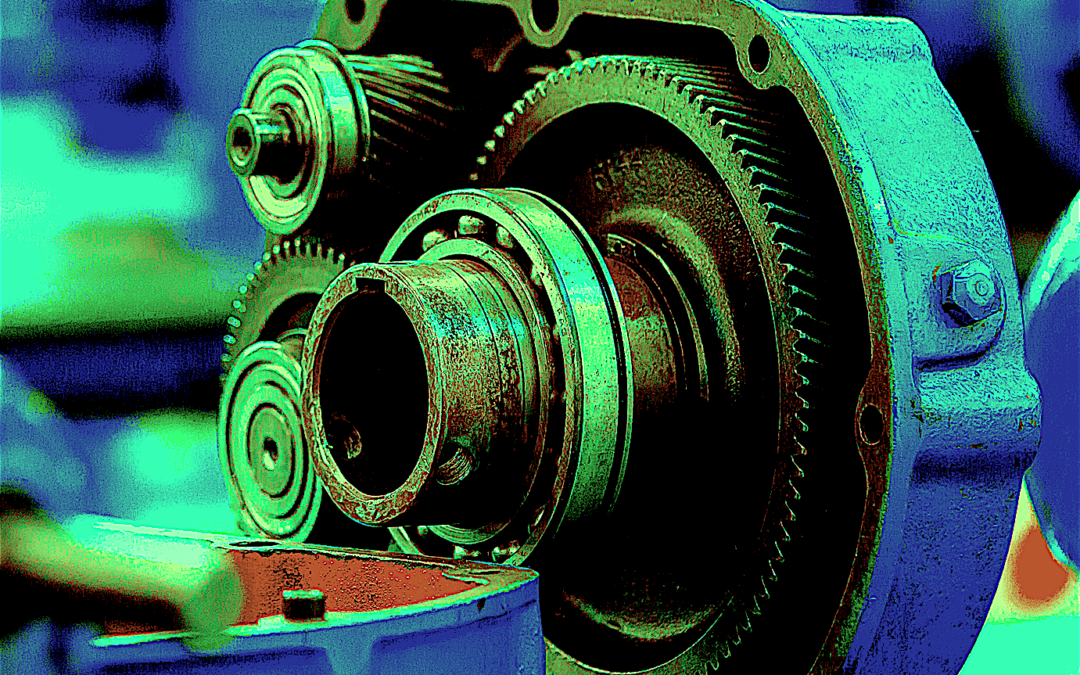

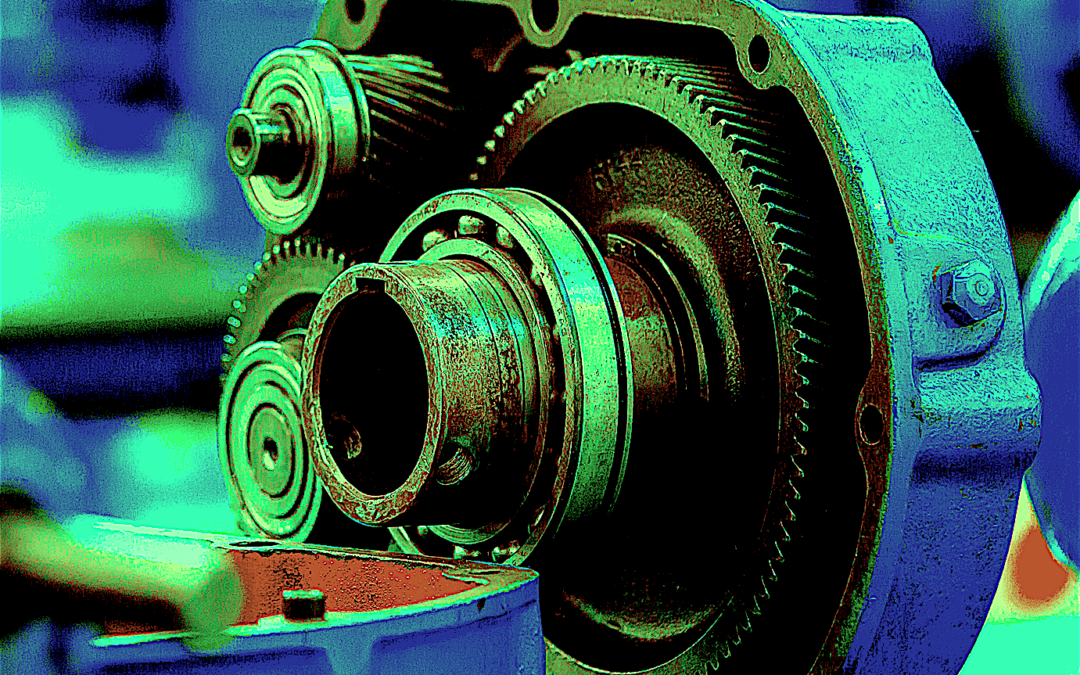

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Feb 14, 2020 | Lubrication Corner, Maintenance Management

There are few definitive studies on rolling-element bearing reliability /life that are based on industry uses and working conditions. There are, however, many claims that indicate the vast majority of such bearings never achieve their engineered-life rating (some...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Feb 10, 2020 | Newsletter Column, Safety Matters

One of the hallmarks of a best-practice maintenance organization is its preparedeness and ability to respond to emergency situations, whether they have occurred or could occur. The definition of an emergency is commonly understood to be a situation or occurrence that...