by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Feb 2, 2020 | Asset Management, The Sustainable Plant

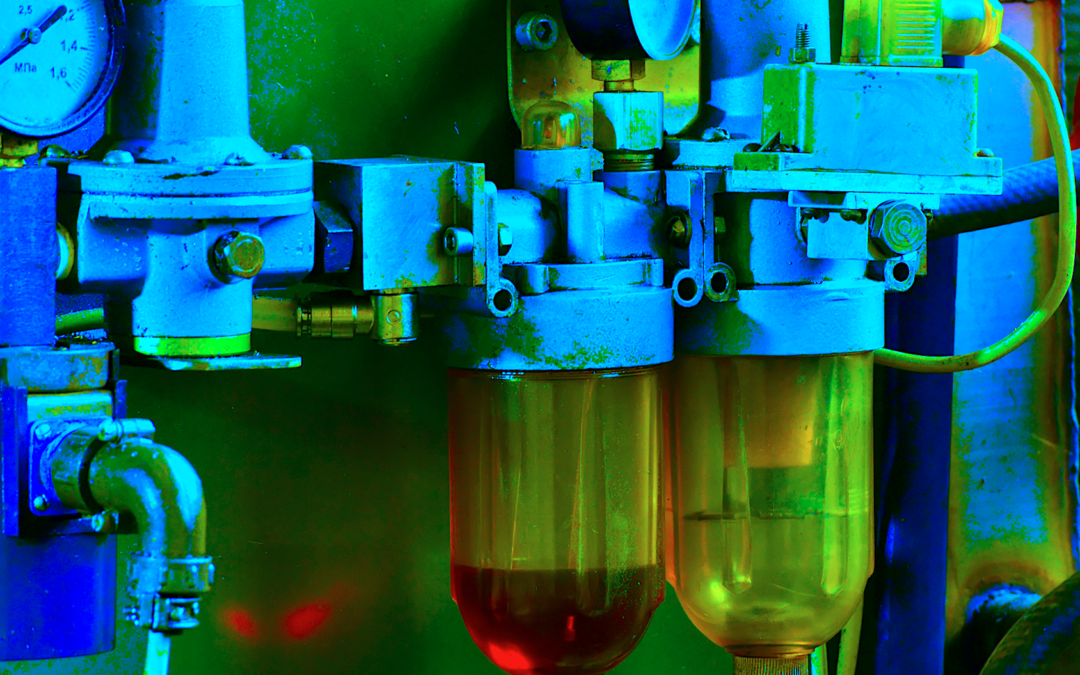

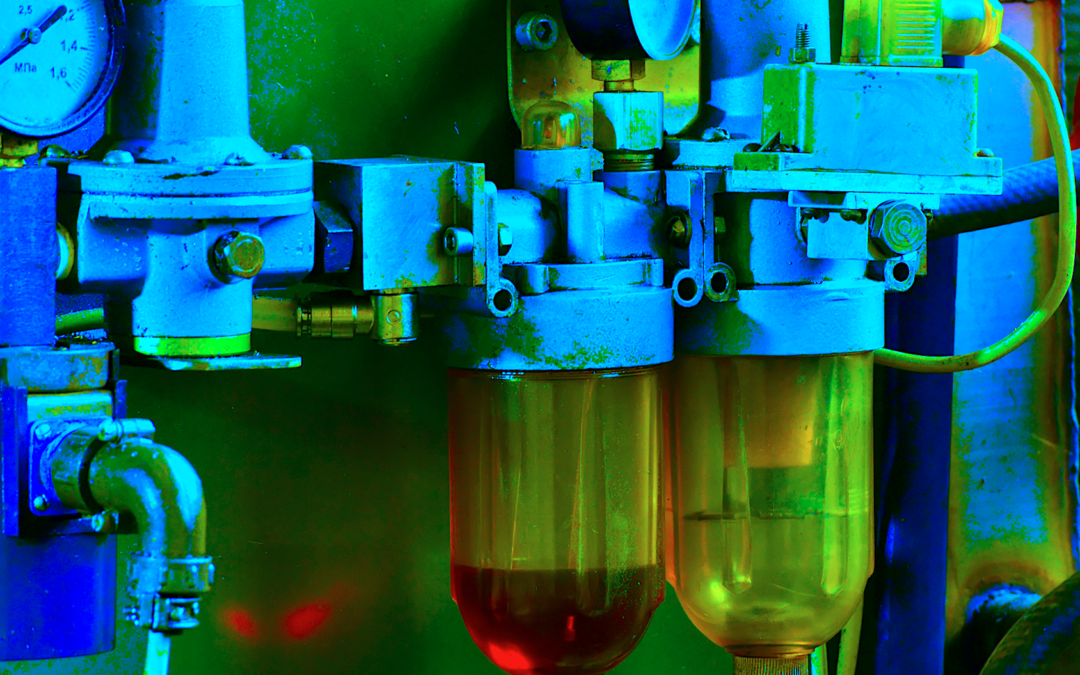

In the first two parts of this series on sustainable-asset-management practices (see links below), we examined how maintenance departments can implement energy-control strategies while using environmentally acceptable/friendly lubrication products. Here in Part III,...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 18, 2020 | Asset Management, The Sustainable Plant

In Part I of this “Fingerprint to Footprint” series (published Jan. 3, 2020), we examined how a maintenance department can easily adopt an energy-control strategy as part of its proactive-maintenance program. Here, in Part II, we discuss a common example of that type...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 3, 2020 | Asset Management, The Sustainable Plant

There’s little doubt that the 2020s are destined to be the decade of a true awakening. Sustainable action focused on containing and reversing the adverse effects of climate change on the planet and our daily lives can no longer be put off. Seemingly endless—and...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Dec 16, 2019 | Asset Management, Newsletter Column, The Sustainable Plant

As the second decade of the 21st century draws to a close, we find ourselves, as individuals and businesses, facing what is arguably the greatest challenge in the history of civilization: the reduction of global warming. The influence of the RAM community on the...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Dec 7, 2019 | Maintenance Management, RAM Tools & Methods

Power transfer from electric motors or engine-drive pulleys to driven shafts by way of chains and sprockets or v-belts is an application of legacy systems that are still very relevant in today’s plant. While these types of driver-driven transmission systems are...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 30, 2019 | Maintenance Management, RAM Tools & Methods

In my Nov. 24, 2019 article for The RAM Review, I focused on the “relationship” factor with regard to what a maintenance department actually controls and what it merely manages. That’s an important distinction when it comes to understanding the...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 24, 2019 | Maintenance Management, RAM Tools & Methods

For a maintenance department to understand the “who” and “what” factors in equipment or process failures, it first must understand what the department actually controls and what it simply manages. There’s a big difference, one that involves the relationships a...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 18, 2019 | Newsletter Column, RAM Tools & Methods

In the retail world, November is celebrated for its “Black Friday” shopping events, during which old stock and “nice to have” luxury items are purchased at what seem to be fire-sale prices by enthusiastic consumers, just in time for the December holiday season. Taking...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 8, 2019 | RAM Tools & Methods

Don’t be misled. “Data” does not equal “information.” Real “information” in areas of reliability, availability, and maintenance (RAM) is derived from the collection of relatable or valuable data that can then be used to make fact-based, management decisions. The...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 25, 2019 | Lubrication Corner, The Sustainable Plant

The search for the right environmentally friendly lubricant (EFL) is an ongoing pursuit in many plants. The results of such quests can differ greatly, depending on an organization’s understanding of the type of product it is actually seeking and how it is to be used....