In the first two parts of this series on sustainable-asset-management practices (see links below), we examined how maintenance departments can implement energy-control strategies while using environmentally acceptable/friendly lubrication products. Here in Part III, we examine the practice of improving the lifecycle of industrial fluids.

Click Here to Read Part I of This Series (General Action Items)

Click Here to Read Part II of This Series (Lube Selection)

At any one time, a corporation could be stocking and using multiple unique lubricants and fluids that may include, among others: compressor oils, crankcase (motor) oils, gear oils, diesel oils, transformer oils, turbine oils, hydraulic oils, metalwork-cutting oils and fluids, and refrigerants. By improving a fluid’s lifecycle—while in storage and in service—less product is consumed, thereby reducing the financial impact on an organization and the stewardship requirements that come when dealing with used oils and fluids in a sustainable manner.

BEWARE THE ENEMY WITHIN

Simply put, lubricant and fluid contamination is, arguably, the number one reason for machine component wear, diminished lubricant/fluid life, and environmentally unfriendly waste oil. Unfortunately, poor cleanliness and maintenance practices are the enemy within and, accordingly, most responsible for contamination issues. By accepting this premise, maintenance teams will find it relatively inexpensive and easy to manage and overcome most contamination issues.

Contamination presents itself in both solid form (dirt) and fluid form (water and other lubricant/fluids). Once industrial lubricants and fluids are accepted and received into the plant, it’s up to the maintenance department to make sure they are stored correctly in a dedicated clean and dry area.

All fluids have a “best before date” that requires maintenance to practice stock rotation in a “First In, First Out” (FIFO) manner ensuring purchase quantities closely match usage patterns that rotate well in advance of expiry dates. Using expired fluids is unadvisable, as their quality and efficacy is likely compromised, which could accelerate machine wear. Expired fluids will also require a sustainable disposal strategy.

If lubricants and fluids must be stored outside, ensure they are protected from excessive cold and heat cycles that can form moisture (water) inside the storage container, and of course, from rain, which can creep through barrel bungs into the product upon opening or if the barrel is not positioned correctly for storage. Water in a lubricating fluid will quickly render it as waste oil and ineffective for lubrication purposes.

Handling and transferring lubricants and fluids from bulk to dispensing containers/reservoirs, requires clean, dedicated equipment for each lubricant/fluid to ensure solids contamination (dirt) is not inadvertently introduced into the fluid before use in the machine. Fine-tolerance bearing surfaces and radial lip seals do not take kindly to lubricants carrying abrasive bodies to the wear surface, yet we continually grease nipples without first cleaning the grease gun and the nipple, leave off reservoir lids and breather caps on hydraulic systems, leave off lubricant container lids, store barrels of lubricants in the outside extremes of weather to rust and collect water, use non-dedicated and dirty lubricant transfer devices.

All lubricants, fluids, and their corresponding dedicated transfer equipment need to be clearly labeled to ensure cross contamination from other incompatible lubricants and fluid does not occur. Conduct a review of your maintenance department housekeeping practices to see if they are focused on keeping contamination in check.

Once lubricant is in a machine reservoir, it is up to the filtration circuit or device to take out moisture and dirt before the lubricant enters the bearing surfaces. Therefore, filters should be changed regularly and, in the case of recirculative lube or hydraulic systems, pressure alarms should be employed to ensure filters do not go into bypass when clogged, which can introduce dirty oil directly into bearings or hydraulic components that eventually cause systems to leak, thus requiring leak and spill-control measures.

Oil leaks and spills are never easy to deal with. Spilt oil and leaked oil and automatically classed as waste oil and must be dealt with in a sustainable manner. Simple prevention through improved fluid handling and regular filtration monitoring will increase fluid life, reduce bearing failure and its associated costs, and result in a more sustainable workplace.

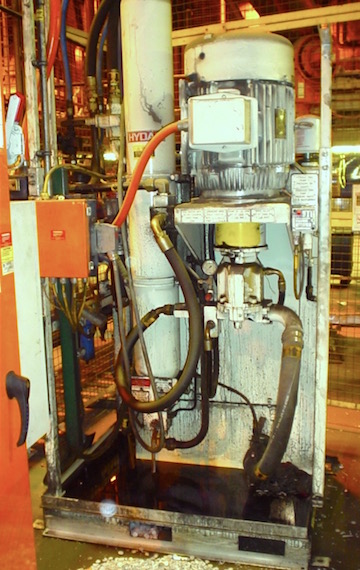

The following photo depicts a 1-yr.-old hydraulic machining station that wasn’t cared for in an appropriate manner. The many seal failures that resulted led to a symphony of leaks, as evident the amount of waste fluid that accumulated in the “catch area” at the base of the machine. In this case, the maintenance department performed a hydraulic fluid “top up” every few days and drained the catch reservoir on a weekly basis.

This 1-yr.-old hydraulic machining station was not maintained appropriately. Resulting seal failures led to countless leaks, as evident by the amount of waste fluid in the “catch area” at the base of the unit.

DISPOSE, RECYCLE, REUSE APPROPRIATELY

In a sustainable workplace, all expired, spilled, leaked, cross-contaminated, and used oils and fluids must be managed in a sustainable manner.

Used oil is generally defined as oil that has been refined from crude oil or any synthetic oil that has been used and, as a result of such use, is contaminated and unsuitable for its original purpose due to the presence of impurities, i.e., water or dirt, or the loss of original properties, i.e., loss of additives. At the same time, used oil is actually “good stuff.”

Like virgin stock oils, used oil should be thought of as a resource that can be reprocessed in situ, employing an industrial filter cart to clean and polish the oil while in the machine reservoir. Or, used oil can be shipped to an recycler where it can be treated through settling, dehydration, filtration, coagulation and centrifugation to remove contaminants and, if needed, refortified with its required additive package and placed back into service—all at a fraction of the cost of new oil, with no disposal-management and associated fees.

According to Safety Kleen Corp., North America’s largest recycler of crankcase oils, “It takes 85% less energy to re-refine motor oil than to produce it from crude stock. In addition, oil re-refining reduces greenhouse gases and heavy metal emissions when compared to burning used oil as a fuel.” Note: For purposes of recycling, it’s important that used oil not be contaminated with hazardous waste. Thus, it must be by manifested and stored separately from all fluids, solvents, chemicals, spilled, and other incompatible products.

Working with a reputable used-oil and oil/fluid disposal company can help a maintenance department fully understand applicable local State and Federal laws surrounding the documentation, handling, and disposal requirements for all classifications of spent fluids and lubricants; determine if a recycle program is cost efficient for a site, and meet the requirements of any in-house or self directed sustainability program.TRR

ABOUT THE AUTHOR

Ken Bannister has 40+ years of experience in the RAM industry. For the past 30, he’s been a Managing Partner and Principal Asset Management Consultant with Engtech Industries Inc., where he specializes in helping clients implement best-practice asset-management programs worldwide. A founding member and past director of the Plant Engineering and Maintenance Association of Canada, Bannister is the author of several books, including three on lubrication, one on predictive maintenance, and his latest, Energy Reduction Through Improved Maintenance Practices (Industrial Press). He’s also writing a new book on planning and scheduling. Contact him directly at 519-469-9173 or kbannister@theramreview.com.

Tags: asset management, lubrication, energy management, sustainability, Green, reliability, maintenance, availability, climate change, used oils, fluids, hydraulics, filtration, contamination control, disposal, recycling