Noise and vibration are measurable losses in the operation of a rotating system, and they can be directly identified in electric motors. As noted in Considering The Direct Energy And Environmental Impact Of Misalignment | THE RAM REVIEW, there are definitive energy losses and greenhouse-gas (GHG) impacts due to misalignment. But what about the losses associated with electric motors? In the following two examples, we will first look at a 1-hp-, 1,800-rpm-motor laboratory test with isolated unbalance to exact minimum specifications. Then we’ll review a field test of a 125-hp, 586-rpm motor. We selected the lower speed motor as I’ve constantly heard about how tolerant low-speed units are to unbalance. This one was also balanced to minimum specification per NEMA MG1, which also meets the rotor balance G2.5 specification of ISO 1940, as noted in Regarding Your Electric Motors: Unbalance and Bearing Life | THE RAM REVIEW.

Even in lighter loads, the unbalance 1X rpm, and any harmonics associated with unbalance, have an impact on rotating components, especially bearings. This situation involves the transfer of rotating energy to these components, which is measured in watts or kilowatts. As we’ve discussed in past articles, the relationships from these losses are found in both energy costs and GHG emissions, as direct and immediate measurements, and related losses increase as the components degrade.

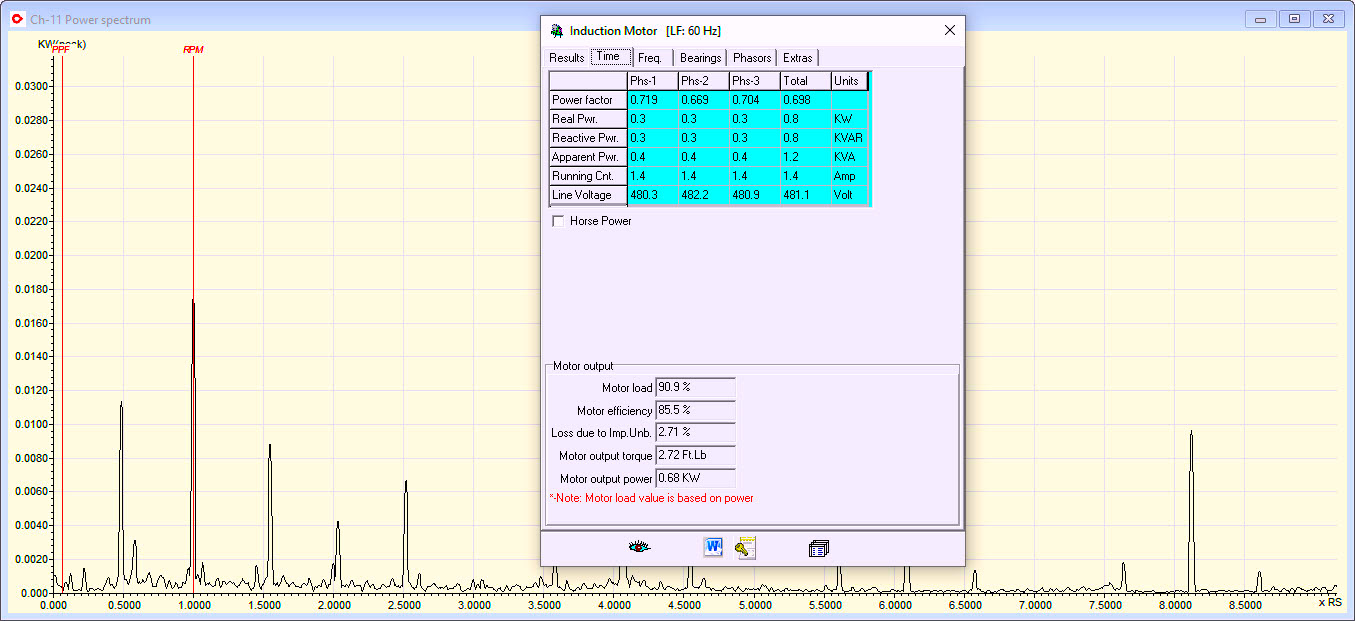

EXAMPLE 1

Our first case is the 1-hp, 1,800-rpm motor in a laboratory with specific conditions introduced. The total input power is 800 watts, and the shaft output is 680 watts. This leaves 120 watts as losses between input power and the shaft. Electrical Signature Analysis (ESA) measurements identify 17.6 watts (2%) of the total energy is associated with the unbalance, as shown in Fig. 1.

Fig. 1. Losses associated with a 1-hp electric motor. RPM relates to unbalance.

If our motor were operating at this average load for 6,000 hours in one year, then the following would apply at $10/kW demand, $0.10/kWh, and 0.707 tons CO2/MWh (all values converted to kW):

Demand = 0.0176kW * $10 demand *12months = $2.10/year

Usage = 0.0176kW*6000 hours*$0.10/kWh = $10.60/year

GHG emissions = ((0.0176kW*6000 hours)/1000kW/MW)*0.707 tons CO2/MWh = 0.075 tons CO2

While the above may seem insignificant, it is a 1-hp motor. In addition to not receiving much in the way of attention, many small-sized units (and their losses and impact) add together very fast. Keep in mind, too, that the above calculation doesn’t include unbalance in driven equipment or other losses.

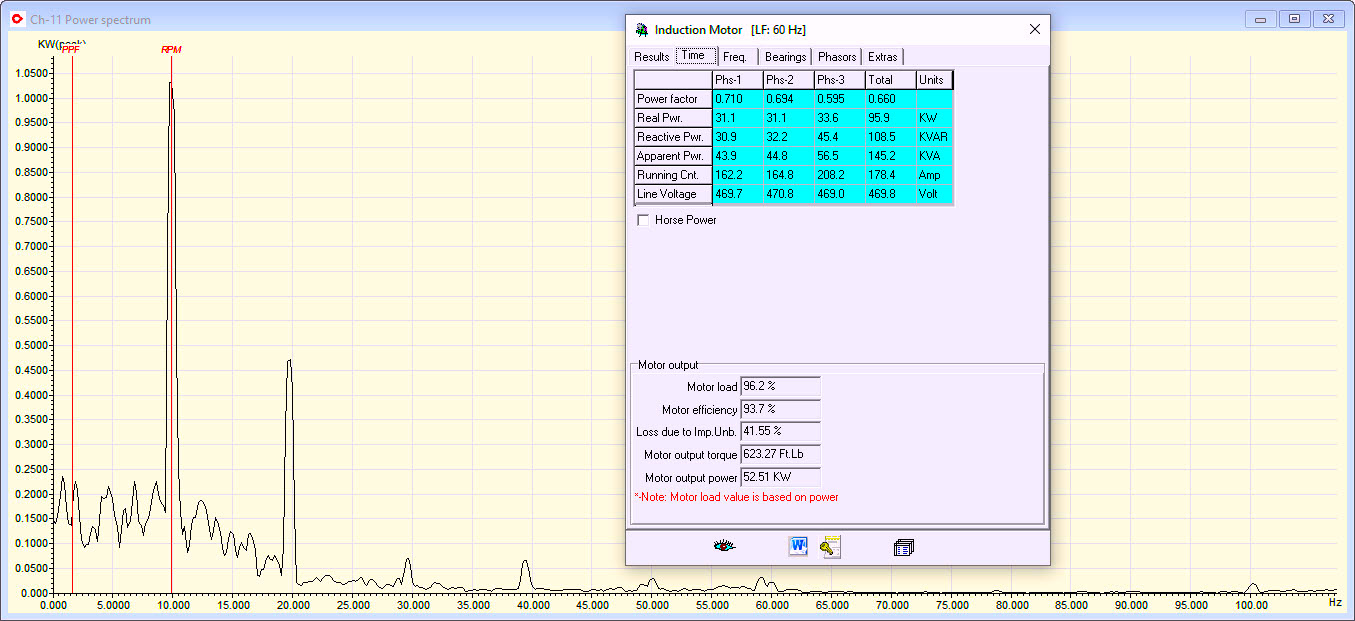

EXAMPLE 2

In our second case, we are evaluating a 125-hp, slow-speed (586 rpm) motor. As shown in Fig. 2, we have a power input of 95.9kW but a shaft power of 52.5kW.

Fig. 2. Losses associated with 125-hp low-speed motor unbalance.

There is a loose connection resulting in a phase impedance unbalance loss of about 41.6%. However, it is noted that there is a 1X RPM loss of 1kW with harmonics totaling just over 0.5kW. A separate vibration evaluation confirmed that this was unbalance and not misalignment. This represents a loss of 1.6% with the following results:

Demand = 1.5kW * $10 demand *12months = $180/year

Usage = 1.5kW*6000 hours*$0.10/kWh = $900/year

GHG emissions = ((1.5kW*6000 hours)/1000kW/MW)*0.707 tons CO2/MWh = 6.4 tons CO2

BOTTOM LINE

It is noted that the losses associated with unbalance go up exponentially in the same way as misalignment. Requiring a standard of ISO 1940 G1.0 increases bearing life by at least a factor of 10, as it relates to unbalance, while also reducing energy and carbon footprint.

When used in combination with other precision-maintenance methods and tools, the reliability of your electrical rotating equipment and loads can be improved at least 10 times versus just meeting minimum requirements. The use of tools such as ESA provides the ability to quantify the impact.TRR

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Maintenance and Reliability Professionals, Atlanta (smrp.org). Email him at [email protected], or [email protected], and/or visit motordoc.com.

Tags: reliability, availability, maintenance, RAM, electric motors, misalignment, unbalance, Electrical Signature Analysis, ESA, greenhouse-gas emissions