A reliability professional’s workday is almost entirely proactive. Such individuals are quasi “Fire Preventers;” they are not “Fire Fighters.” They use much of their available time to obtain answers to three questions:

1. Is an upgrade possible or do we have to live with what we presently have?

2. If upgrading is feasible, is the upgrade cost-effective?

3. Which innovative technology provider should be selected to implement a

combination of repair and upgrading at the next opportunity?

Needless to say, reliability professionals work with innovators and reward them for becoming the user’s technology resource. They assist reliability professionals in developing and explaining payback calculations. Together, they perform upgrade research on Beta-sites and document their experience. Both participate in analyzing the field experience at other client sites; this can be done without breaching confidentiality.

The two parties often join in making a presentation to the reliability professional’s management. At many Best-in-Class (BiC) companies, making such presentations is considered part of a structured MQA (“Machinery Quality Assessment”) process, the cost of which should be included in the user-purchaser’s budget. The MQA activity largely contributes to decades of future machinery reliability. Accordingly, BiCs include the money for MQA in their up-front budgets. Details are given in some of the texts you’ll find in the downloadable PDF of the book list that typically follows my weekly articles for The RAM Review (specifically References 1 through 4 below).

MQA AND NEW MACHINES

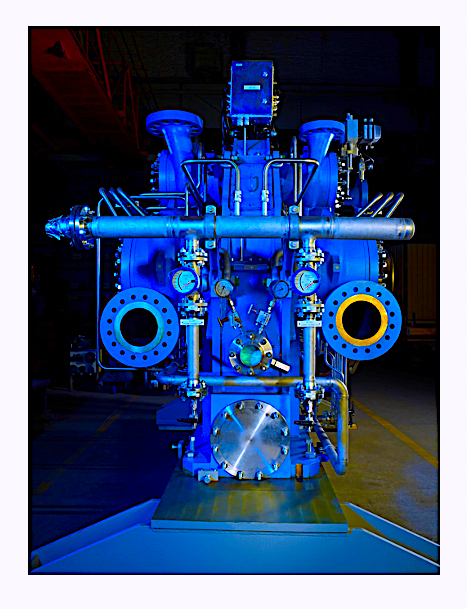

As a brief example of MQA for large and important machines, let’s consider the super-sized integrally gear-driven compressor from MAN Energy Solutions (man-es.com) shown in Fig. 1.

Fig. 1. Large integral-gear-drive, 8-stage turbocompressor.

Fig. 1. Large integral-gear-drive, 8-stage turbocompressor.

(Source: MAN Energy Solutions, Augsburg, Germany)

When the purchaser’s representative examined the design drawings and bills-of-materials for a similar multi-stage machine at the compressor manufacturer’s factory, he realized that, although specified for clean gas service, not all stages were equipped for dry gas seals. He negotiated a solution whereby space would be “designed-in” to allow retrofit of such seals after one of the leading seal providers had accrued enough experience to qualify as a seal supplier. In other words, space was incorporated in the machine layout to accommodate what was, then, a non-existent seal design to be discussed during an unspecified future Inspection and Repair Shutdown (IRD) event that might present itself years down the road. And, indeed, that occurred: roughly six years later.

It should be noted that MQA is a well-planned activity for which the cost (usually no more than 5% of the asset’s price) is budgeted and allocated. At BiC (Best-in-Class) companies, machines ranging from important 10-kW process pumps to huge 75- MW turbo-compressor trains are reviewed, analyzed, and critiqued by engaging in well thought-out Machinery Quality Assessment.

MQA AND EXISTING MACHINES

While originally devised for large machines that are about to be built, the MQA approach has also been used to evaluate existing fluid machines or the critical components, such as mechanical seals, which, by themselves, reflect one of the most difficult reliability issues in a process plant.

Using mechanical seals as our example, let’s consider how reliability professionals would obtain the product that best meets their facility’s reliability focus. As a general rule, the single-sourcing of any critical component is acceptable for some products. However, single-sourcing should be discouraged for engineered mechanical seals and similar products where you purchase application engineering know-how.

Instead of single-sourcing, three or four competent suppliers or cooperative manufacturers should be invited to offer superior mechanical seals, propose the right rolling element bearings, offer only service-optimized gaskets, and so forth. Successful networking among one’s peers makes us well informed; it will ultimately benefit both seller and buyer.

COMING UP

In my next article for The RAM Review, the focus will be on use of the MQA approach to identify superior mechanical seals for a difficult process pump in an existing plant. A subsequent article will then look at MQA and the important issue of seal-flush plans.TRR

SPECIFIC MQA REFERENCES

1. Bloch, H.P., and F.K. Geitner, Compressors: How to Achieve High Reliability and Availability, (2012) McGraw-Hill Publishing, New York, NY, ISBN 978-0-07-177287-7

2. Bloch, H.P., and F.K. Geitner; Maximizing Machinery Uptime, (2006) Elsevier Publishing, Oxford, UK, and Cambridge, Massachusetts, USA; ISBN-13: 978-0-7506-7725-7

3. Bloch, Heinz P., Petrochemical Machinery Insights, (2016) Elsevier Publishing, Oxford, UK, andCambridge, MA, ISBN 978-0-1 2-809272-9

4. Bloch, H.P., Pump Wisdom: Problem Solving for Operators and Specialists, (2011), John Wiley & Sons, Hoboken, NJ; ISBN 9-781118-04123-9

Editor’s Note: Click Here To Download A Complete List Of Heinz Bloch’s 22 Books

ABOUT THE AUTHOR

Heinz Bloch’s long professional career included assignments as Exxon Chemical’s Regional Machinery Specialist for the United States. A recognized subject-matter-expert on plant equipment and failure avoidance, he is the author of numerous books and articles, and continues to present at technical conferences around the world. Bloch holds B.S. and M.S. degrees in Mechanical Engineering and is an ASME Life Fellow. These days, he’s based near Houston, TX. Email him at heinzpbloch@gmail.com.

Tags: reliability, availability, maintenance, RAM, machine-quality assessments