As events occur throughout the economy and energy costs continue to rise, all opportunities for energy efficiency should be explored as part of an organization’s effort to be profitable. In operations that use large amounts of compressed air, such as packaging and food processing, the greatest savings can be found by dealing with leaks and general efficiency of the system. Even with higher-efficiency compressors and motors, the average for 1 horsepower of compressed air is 9 to 10 horsepower of prime mover.

A good leak program that includes leak-tag and airborne ultrasound has the potential to reduce associated costs by 30 to 40%. This means that for a larger packaging system operating with five 200-kW compressors at full load, the elimination of compressed air leaks could decrease the total from 1000 kW to ~600 kW and allow the shutdown of two of the compressors, i.e., result in reduced loading.

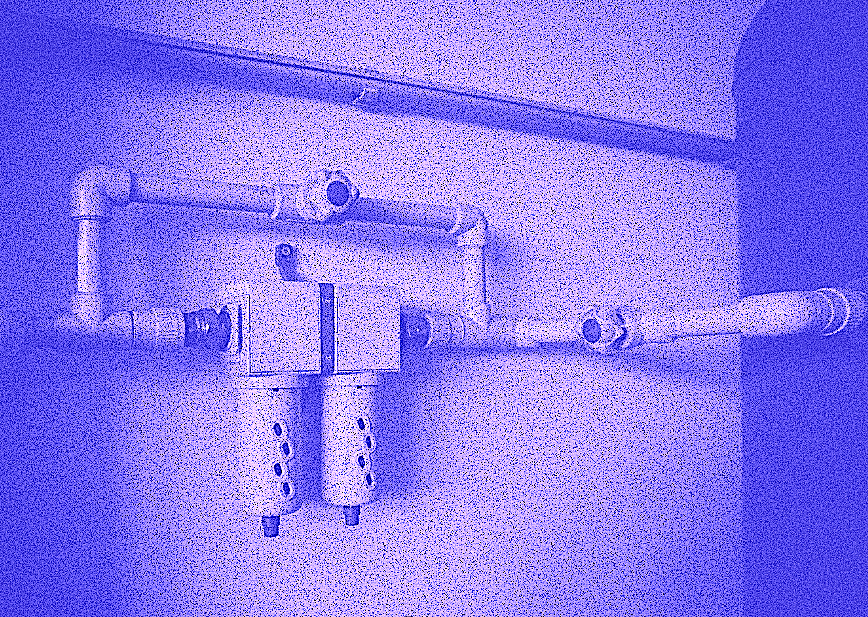

The widespread thinking across industry is that compressed air is free. It’s not. As noted by the U.S. Department of Energy (energy.gov) publication, Improving Compressed Air System Performance: A Sourcebook for Industry, leaks are present in couplings, hoses, tubes, fittings, pressure regulators, condensate traps, shutoff valves, pipe joints, disconnects, and thread sealants. A leak from a small opening (1/16-inch) at 100 psi wastes 6.5 CFM of compressed air, at an approximate cost of $1,050/year. That’s significant for an inaudible leak.

A good estimate for finding leakage can be performed during production downtime where compressors have start/stop or load/unload controls. When all end-use pneumatic equipment is turned off, the times to load and unload can be recorded. Where large T is the on-load time total in minutes and small t is the off-load time in minutes, we can see the percent of total leakage (%L) as percent lost CFM, as shown in Equation 1 (below).

%L = (T*100)/(T+t) Eq. 1

When we determine the CFM/kW, we can review the total cost associated with the losses. For instance, if we have a 200-kW screw compressor that produces 5.5 CFM per kW (1100 CFM) we can calculate the total kW per hour for lost CFM from Equation 1, as shown in Equation 2 (below). For example, if we note that we are losing 30% of the total (1100 * 0.3 = 330 CFM) to feeding leaks across 8,760 hours per year at $10/kWh we come up with the following:

Leak Cost = (330 CFM/(5.5 CFM/kW))* $0.10/kWh*8,760 hours = $52,560/year Eq. 2

Taking the direct and indirect impact of CO2 emissions into consideration, we see the following associated costs. They have the potential to increase the overall cost of our example leak from $52,560/yr to $82,320/yr.

1. Emissions at 0.707 ton/MWh (US EIA 2020 average for USA) =

525.6 MWh * 0.707 Ton CO2/MWh = 372 Ton CO2/yr

2. Social costs at $51/Ton (US EPA 2020 Value at 2.5%) =

372 Ton CO2/yr * $51/Ton = $18,972/yr

3. If involved in Cap and Trade with an average cost of $29/Ton carbon credit

(as in California at the time of this article) = $10,788/yr

In most of the cases where we’ve conducted energy surveys, including surveys of compressed air for packaging pneumatics, vacuum systems, and other production systems, application of a simple compressed air leak program has allowed us to take compressors off-line. In every case within industrial systems, the simple payback is the norm.TRR

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Maintenance and Reliability Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: reliability, availability, maintenance, RAM, compressed air systems, electric motors, energy efficiency