Voltage unbalance and its most severe form, single phasing, cause up to 14% of power-quality-related motor failures.

It’s important to understand that maximum current unbalance is not defined in standards for electric motors in their operating environment, due to potential variations in motor design and circuit-impedance unbalance. Voltage unbalance, however, is defined in standards such as the National Electrical Manufacturers Association (NEMA) Motors and Generators Standard 1 (MG-1), which includes the direct impact on the operating life and characteristics of the electric motor through 5% unbalance.

Voltage unbalance is relatively easy to calculate. It requires the measurement of the phase-to-phase voltage of the supply to the electric motor.

The first step is to add all three voltages together and divide by three, which provides the VA (Average Voltage), then take the furthest voltage of the three from that voltage as a positive number and divide by the VA and multiply by 100%.

EXAMPLE:

If you have Va-b = 465 V; Va-c= 480 V; and, Vb-c= 467,

then (465 V + 480 V + 467 V)/3 = 471 VA,

which results in ((480 V – 471 V)/471 V) * 100% = 1.9%.

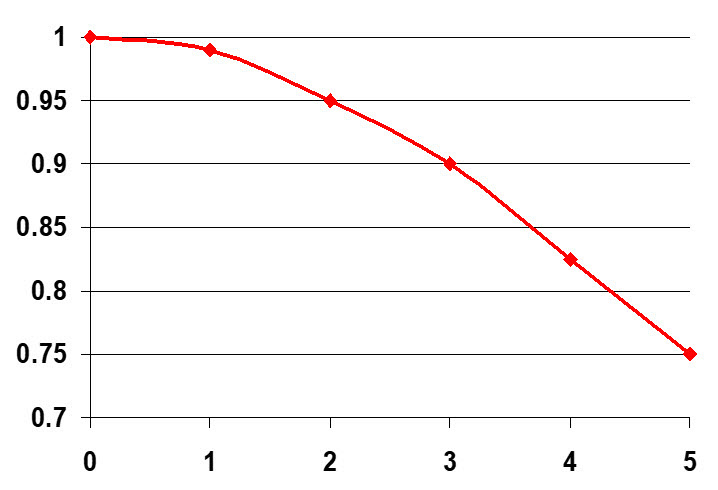

When applied to Fig. 1, the horsepower is mulitiplied by the voltage-unbalance derating factor, or 0.95 for this example. In effect, a 10-hp motor would have to operate as a 9.5-hp motor.

Fig. 1. Voltage-unbalance derating factor

While many mistakenly use current unbalance to determine the condition of an electric machine, such values can only be used to trigger an investigation. Another trigger would be loud electrical humming or electrical growling noise, which would indicate a possible single-phasing condition.

The single-phase condition involves the complete loss of one phase. A lightly loaded motor may run for an extended period of time, as the phases may not draw enough current to trip a standard overload. Electronic overloads are more common now, and can be used to detect voltage unbalances and single phase conditions.

Other than utility issues, such as loss of only one phase coming into a facility, other conditions that can cause phase balance include:

-

- damaged conductors and loose/open connections;

- starter contacts worn or overloads failing;

- improper transformer taps;

- transformer problems;

- too many single phase loads on one phase of transformer(s);

- power-factor-correction-capacitor problems; and,

- circuit-impedance problems.

Once a voltage unbalance is detected, it becomes important to identify the cause. However, if you do observe a current unbalance with a low voltage unbalance, you can see if it can be corrected, or identify the cause, by rotating and rechecking the current. This is performed by moving phase A to phase B, phase B to phase C, and phase C to phase A, which does not change the direction of rotation.

Re-check the current, and if the unbalance stays on the same motor phase, you’ll know it is related to the motor. If it rotates with the phase rotation, it is supply-related.

On smaller motors (under 20 hp), you may see the phase current balance after the phases are rotated. Motors in sizes through 300 hp may be wound in such a way that a small current unbalance might occur without measureable voltage unbalance.

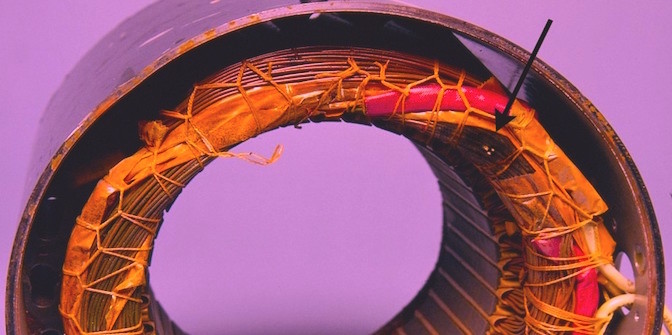

Fig. 2. Winding failure following greater than 5% voltage unbalance for ~36 hrs.

The failure of a motor due to voltage unbalance or single phasing is very specific. As shown in Fig. 2 above, windings overheat alternately with those that do not, leading to a motor with alternating burned and unburned windings. The exact pattern depends on the motor connection, but the appearance (see arrow) is similar regardless. The excess heading in these conditions will reduce the motor life significantly and cause the unit to operate with lower efficiency.TRR

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email howard@motordoc.com or info@motordoc.com and/or visit motordoc.com.

Tags: induction motors, VFDs, power quality, single phasing, electrical systems