Supply-chain interruptions are still with us. In fact, for many business sectors, there seems to be almost no end in sight. Add to these interruptions the rising prices of goods and services. As a result, there will be many opportunities for decisions that undermine reliability improvements and contribute directly to equipment failures. We have experienced these types of costly supply-chain/economy-induced equipment failures in past recessionary times. Consider the following example from a real-world manufacturing operation.

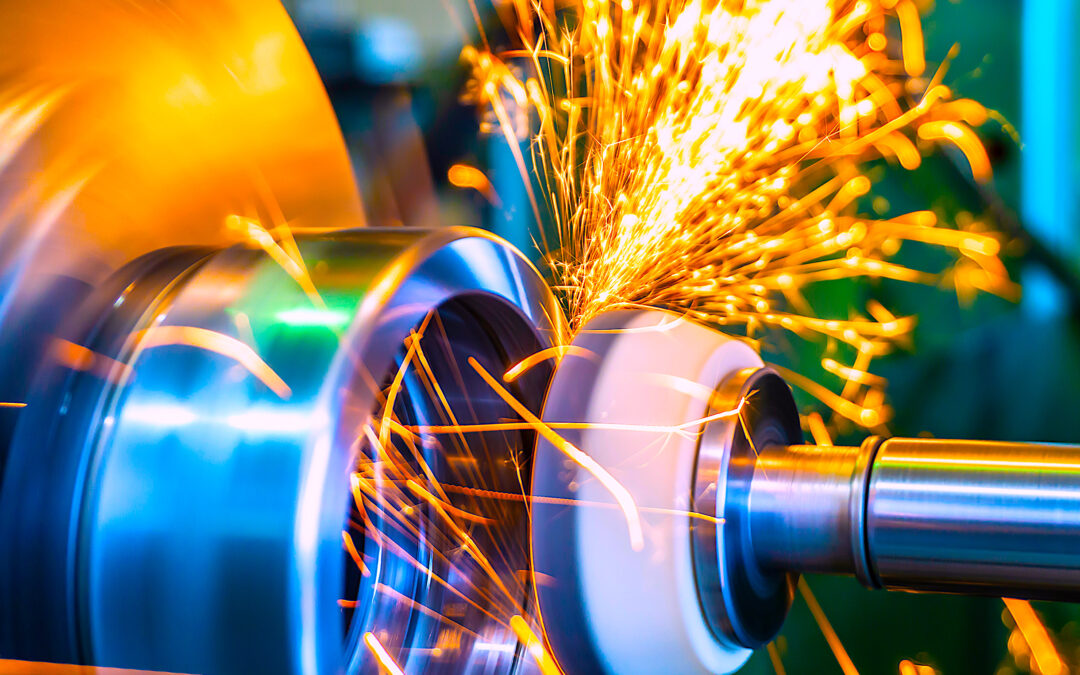

While the company’s global business was booming and orders for its domestically manufactured products were increasing, the business was aggressively trying to reduce the cost of raw materials and boost equipment uptime to reduce the overall cost of manufactured parts. During a plant assessment, we learned of bottlenecks in the small-crankshaft-machining line that top management labeled “equipment problems.” One machine was exhibiting chronic failures of a high-speed spindle. The other “problem” was an increase in processing time and defects.

Spindle failures on the machine in question had been diagnosed by the site’s maintainers and engineers as “a bearing problem.” Unfortunately, the bearing supplier couldn’t ship replacements on an as-needed basis and delivery times were increasing. To alleviate the problem, the decision was made to remove several rolling elements to allow room for more lubrication in the bearings and prevent galling and pitting. While this approach worked for a while, the problem returned, along with machining irregularities.

Following a brief root-cause analysis discussion and observation, we noted several inconsistencies that caused the bearing failures and ultimately led to unplanned downtime:

1. The spindle’s lube oil was stored at the machine in an open container.

2. The fine-mesh screen in the oil-reservoir-fill-opening was missing.

3. The spindle’s oil reservoir contained fine metal particles.

The increasing processing time and defect rate was another matter. The crankshaft-machining line contained six machines (including the one with the spindle bearing problem). It started with rough machining of castings and ended with finish grinding.

A rapid decline in the quality of the small castings was noted by the first-stage rough-machine operators. Some parts were too rough to clamp in the fixtures and others “didn’t look quite right” after being machined, at which point they were scrapped. Alas, the supervisors basically said, “Get over it and make parts.”

So, make parts the operators did, through the next four machining stages. At the final grinding stage, the finish diameter still didn’t meet quality specifications. That’s why approximately 10% to 15% were rejected when the batches were sent for quality inspection. This was a significant increase from the previous 2% defect average.

Another brief root-cause analysis discussion revealed that a new casting supplier had been selected several months prior. What changed with the new castings? Some exhibited small pits and a casting-mold mismatch. Those defects resulted in parts that couldn’t be machined or ground to meet quality requirements. As for why a new supplier was chosen, company buyers found they could save a few pennies per casting, which would help reduce manufacturing cost.

The casting issue was ignored because top management saw savings in the cost of raw materials. Shop-floor supervisors, in turn, were charged with making more parts. This led to machining of parts with observed defects at the very beginning of the process. Had the spindle-oil-contamination issue been prevented, the bearings would not have failed, and the bearing-supplier issue might not have become a problem.

The lesson for RAM pros from this story is that we should always be mindful of external supply-chain issues. What’s more, we should remain ever vigilant in preventing those issues from clouding our reliability mindset and approaches to assuring optimum equipment performance.TRR

ABOUT THE AUTHOR

Bob Williamson is a long-time contributor to the “people-side” of the world-class-maintenance and manufacturing body of knowledge across dozens of industry types. His vast background in maintenance, machine and tool design, and teaching has positioned his work with over 500 companies and plants, facilities, and equipment-oriented organizations. Contact him directly at 512-800-6031 or bwilliamson@theramreview.com.

Tags: reliability, availability, maintenance, RAM, asset management, supply chain interruptions, bearings, spindles