The challenge with detection of rotor issues in synchronous machines, i.e., motors and generators, so I’ve been told, is that such machines have no slip. If that argument were to hold true, you would not be able to detect rotor defects in synchronous machines. In my experience, though, the opposite is true. When defects do occur in the rotating fields of a large synchronous machine under load, they stick out. With rotating-field defects, the machine will slip out of its synchronous mode and then be kicked back in again, causing a signature.

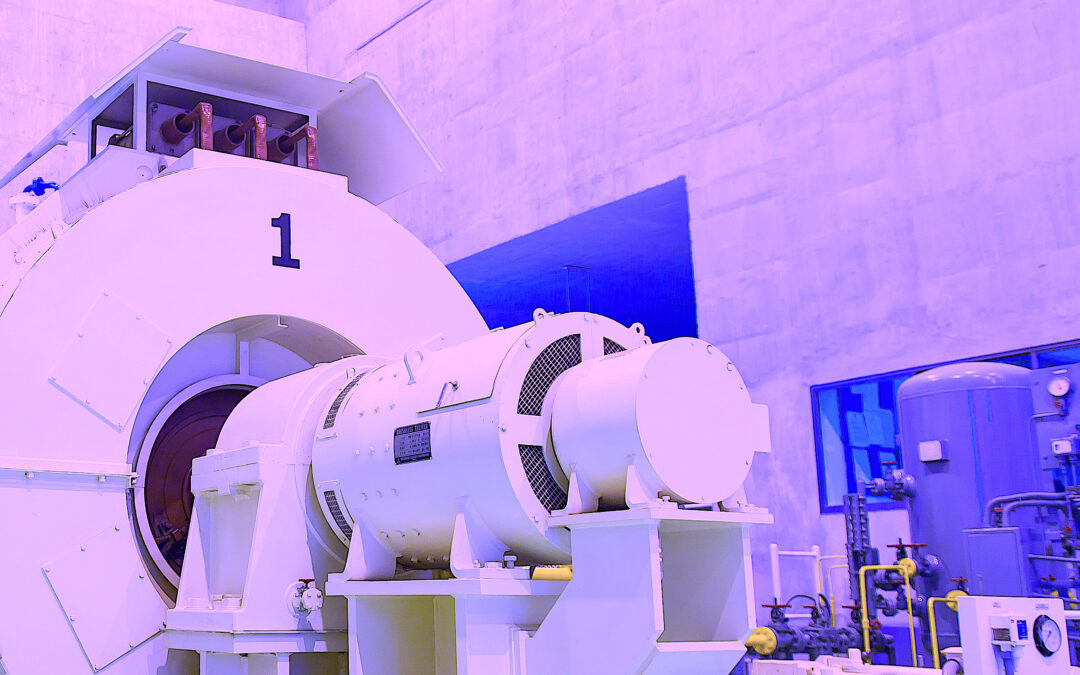

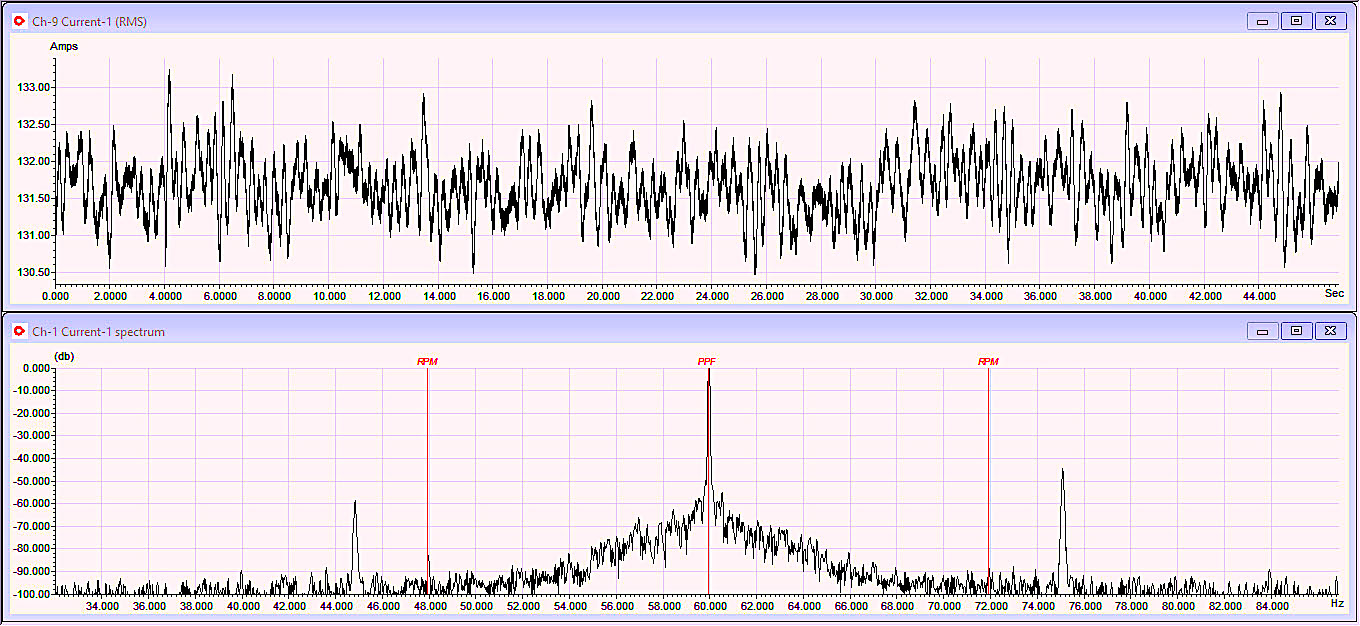

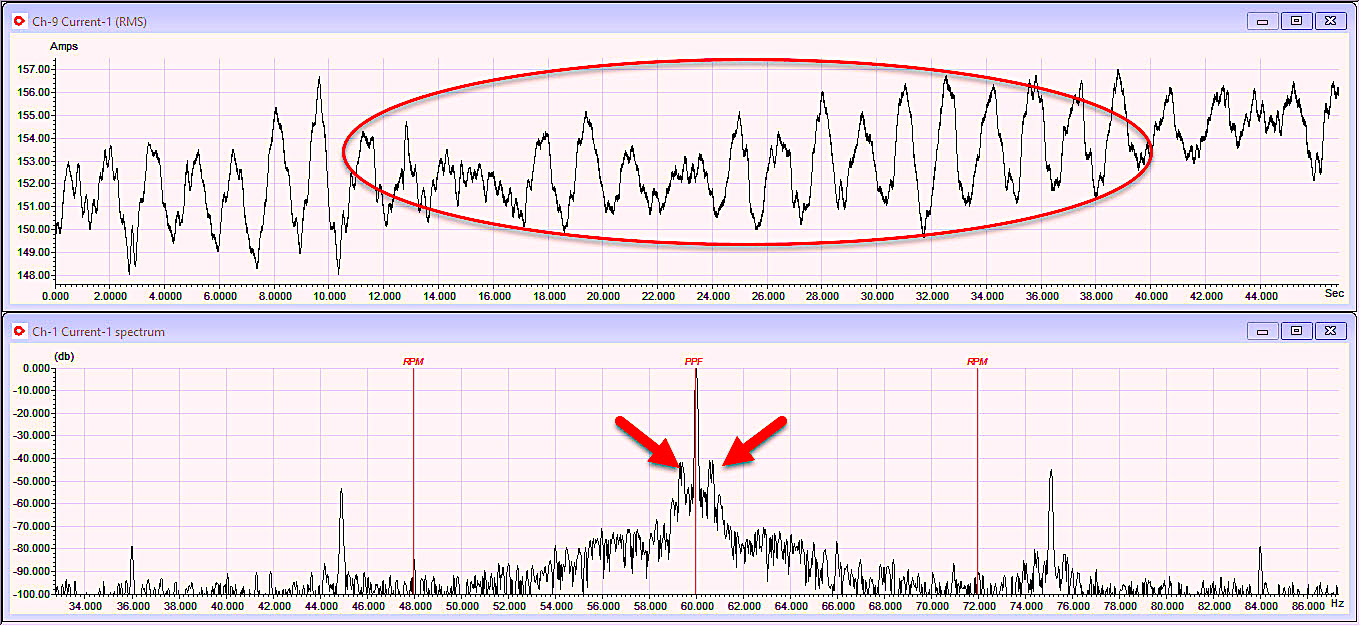

We can use Electrical Signature Analysis (ESA) to detect faults dynamically and Motor Circuit Analysis (MCA) for evaluating the rotor statically. First, we’ll compare a good and bad rotor with ESA by looking at the low-frequency “good test” (Fig. 1) in comparison to the low-frequency “failed test “(Fig. 2).

Fig. 1. Good signature from a 1,500 -hp, 720 rpm synchronous motor.

In Fig. 1, we can see “noise” around the 60Hz line frequency, but no specific peaks. This situation is related to turbulence or cavitation, be it from a pump or compressor. In Fig.. 2, we see regular changes to the RMS (root mean square) current (top part of image) and specific peaks (red arrows) surrounding the line frequency that look like Pole-Pass Frequency (PPF). This, in fact, is a PPF signature, because of potential damage to the rotor fields that would cause the unit to fall out of synchronous and then pop back in once the ammortisseur windings come into play. In some cases, there would be an additional 1X rpm reading and sidebands around line frequency of the number of poles squared.

Fig. 2. Synchronous motor with failing field circuit (shorted).

There are several ways to confirm a rotor-field defect, including: insulation-to-ground test; pole-drop tests; and MCA testing. For all of these tests, the rotor fields must be disconnected from the excitation system to avoid potential damage.

An insulation-to-ground test is usually performed first, as a grounded field will also cause the same type of result. With the pole-drop test, as performed in accordance with IEEE Std. 115 (“IEEE Guide: Test Procedures for Synchronous Machines”), an AC voltage is applied across all of the fields at once and voltage is measured across each set of field coils. The coils should be within 5% of the average. Outliers should be set aside as damaged/shorted. If the rotor is still inside the stator, the shaft position should be considered, and the stator grounded.

For in-place testing, an MCA coil test is usually more than sufficient to identify any defects in a synchronous rotor. In a low-voltage test of this type, the full circuit may be tested and compared to a prior test or compared to an identical motor. In both cases, the position of the rotor is critical in comparison, as the stator winding will appear as the secondary of a transformer and the relationship between the field coils and stator coils can affect test results.

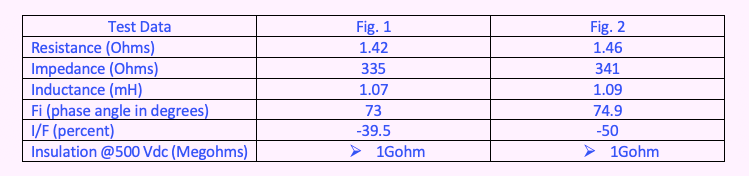

Note: When comparing two machines, it is sometimes necessary to test each one in multiple rotor positions. As shown in Table I, the test results comparing Fig. 1 and Fig. 2 confirm that Fig. 2 has at least one shorted field.

Table I. MCA Data from Fig. 1 and Fig. 2 Synchronous Motors.

Table I. MCA Data from Fig. 1 and Fig. 2 Synchronous Motors.

Based on the differences noted in Impedance, Fi, and I/F, some of the readings differ significantly from the others. MCA provided the second qualifying test to confirm that action should be taken to perform corrective measures, rewinding the rotor. Having a baseline test of the unit should also be considered. That way, data is directly comparable when it comes to troubleshooting.TRR

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Maintenance and Reliability Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: reliability, availability, maintenance, RAM, electric motors, generators, synchronous machines, pumps, compressors, motor testing, generator testing, Electrical Signature Analysis, ESA, Motor Current Signature Analysis, MCSA