My recent series of discussions in The RAM Review (see links below) have focused on the topic of workforce-development strategies and planning. As I’ve mentioned before, workforce development is not merely training. In this article, I discuss how competency building can be the ultimate approach to a strategically developed workforce, not just for today, but well into the future of our industrialized world.

What do we mean by “competency?” Simply put, a competency is what an employee must be able to accomplish on the job, the desired results or outcomes resulting from training and experience on the job over time.

Workforce training, though, is NOT necessarily competency building. But training in knowledge, skills, and abilities (job tasks) form the basis for building competence. It takes a lot more than knowing about the different types of pumps and how they work to qualify a person to correctly remove and replace a specific pump in your plant. Workforce development must result in competency building, if a business is to benefit from its “training programs.”

Let’s climb one level higher to “strategic workforce development.” At this level, the employees’ development is focused on building the necessary competencies for assuring reliable performance of the company’s critical assets. That’s workforce development focused on the ingredients for business success, versus “training” in the hopes of improving business performance. Remember this: Workforce development with a strategic intent that builds employee competence will always benefit the business.

EXAMPLE: COMPETENCY BUILDING WITH A STRATEGIC INTENT

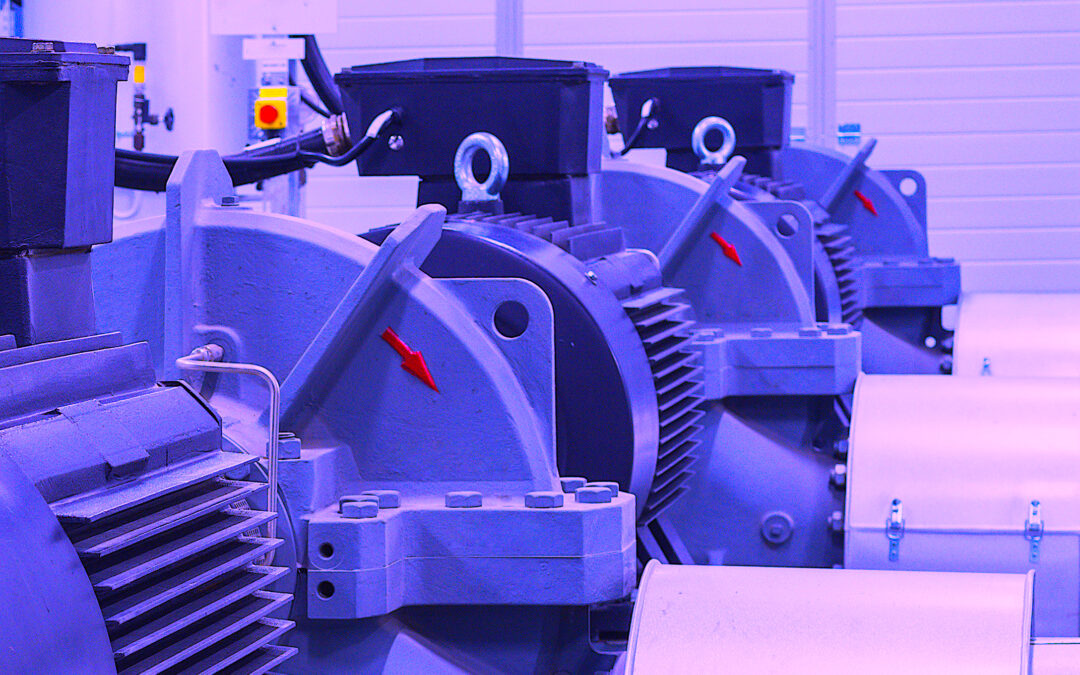

Looking at a critical manufacturing-process line XYZ, we find a variety of motors, pumps, valves, piping, tanks, sensors, controllers, and the like. All these elements must perform together as a single system as designed to achieve the production goals of the business. However, in this case, there’s been an increasing recurrence of reliability issues with the process line in recent months. Production reports indicate a slight increase in minor glitches, slowed production, and restarts. Looking at work-order histories and recent spikes in process-line failures, we discover a spate of pump problems. What changed?

The short answer? Not much. Process line XYZ operates the same amount of time each day, week, and month. The process stream utilizes the same raw materials, utilities, temperatures, pressures, and flows as it was designed to run. Apparently, nothing changed in the process parameters.

What about maintenance? Process line XYZ depends on routine preventive maintenance (PM) inspections and lubrication. A twice-yearly line shutdown for repairs and replacements is part of the maintenance protocol. The maintenance routines have not varied. The types, sources and manufacturers of materials, supplies and pumps have not changed either.

What about the people side of the process line? The same operators, supervisors, and process-control technicians have worked line XYZ for that past 5 to 10 years. The same maintenance mechanical, electrical, and controls technicians have worked on the line for years as well. Well almost. The new mechanical technician (let’s call him Joe) came to the company with a powerful background as a proven performer. But Joe was junior on the maintenance crew. That’s what changed!

Long story short, this new employee was very capable and experienced. But his weakness was in pumps. Specifically, the types of pump installations in the XYZ process line. Being junior on the crew, Joe was assigned to remove and replace several ABC pumps during the previous bi-annual shutdown. The pumps were being replaced with in-kind units, including the necessary couplings and gaskets. What could go wrong with that?

Simply put, the new Joe did not have the required competence to remove and replace THESE pumps, in THIS specific process line. The good news? We now know exactly where to focus his next-steps developmental training.

Removing & Replacing ABC Pumps On The XYX Line

Let’s begin this section by stating the competency, the desired outcomes from this specific employee-development process. To be qualified, Joe should be able to “Remove an ABC pump from service in process-line XYZ, replace with in-kind, and restore to full operation safely, according to company policy, procedures, and OEM recommendations within 2 hours.”

What knowledge, skills, and abilities (KSAs) are required for Joe (or any other employee, for that matter) to achieve this level of competence? Think of these KSAs as job-performance requirements, such as job tasks. However, the competency statement above is more than an accumulation of job duties and tasks. The stated competency requires a mix of tasks and an advanced level of synthesizing multiple tasks coupled with guided experience on process line XYZ and pumps ABC over a period of time.

Now let’s consider a list of the job tasks that would normally set the foundation for the specific competency of removing and replacing the ABC pumps on process line XYZ. Use observable verb statements for each task.

To remove and replace pumps, an employee must be able to do the following:

-

-

-

- Follow lock out-tag out-try procedures.

- Use maintenance work orders.

- Use OEM installation bulletins.

- Select and using hand tools.

- Identify pressure sensing devices.

- Identify and selecting threaded fasteners.

- Tighten & torque threaded fasteners.

- Install flange gaskets.

- Align shafts with lasers.

- Select and install couplings.

- Identify pump types and functions.

- Identify pump lubrication & methods.

- Check pump rotation.

- Check for pump soft foot and compensate.

- Check for pump vibration.

- Detect and correct pipe spring.

- Identify pump damage & failure modes.

- Perform pump prestart maintenance.

- Verify proper pump operation.

-

-

While this list is in random order and may not be complete, you get the idea. There are many, many tasks someone must master before learning to remove and replace pumps, especially ABC pumps on process line XYZ. But it’s more than learning. Competency requires the ability to perform the job flawlessly according to the competency statement above. Again, that’s the strategic intent of workforce (n this case, “employee”) development.

Developing An Employee Training & Qualification Plan

Let’s put the pieces together for a competency-building process that expands on the basic tasks and leads to an employee qualified to perform a critical job duty.

Step 1 – Specify the desired job-performance competency. “Remove an ABC pump from service in process line XYZ and replace with in-kind, restore to full operation safely according to company policy, procedures, and OEM recommendations within 2 hours.”

Step 2 – Reverse engineer the competency to identify the basic knowledge, skills, and abilities (tasks) required for the stated competency. (see the list started above)

Step 3 – Identify which tasks the selected employee (trainee) already knows and can perform. When in doubt ask for a performance demonstration.

Step 4 – Focus training & qualification activities on the known skills, knowledge, and ability gaps. Develop a training plan and schedule outlining what, when, where and who will be the coach/facilitator of training.

Step 5 – Utilize four-step OJT methods and qualify each task with a performance demonstration. (See my previous discussion “Making on-job training effective and efficient”)

Step 6 – Begin competency building to qualify the employee to “Remove an ABC pump from service in process line XYZ, replace with in-kind, and restore to full operation safely, according to company policy, procedures, and OEM recommendations within 2 hours.”

-

-

- Utilize four-step OJT methods repeating steps 3 and 4 through several pump

removals/replacements. - Qualify the employee at the “competency statement” level by a performance

demonstration on Process line XYZ and pump ABC.

- Utilize four-step OJT methods repeating steps 3 and 4 through several pump

-

WORDS TO THE WISE

All too often we have tended to short cut training, to look for a quick way out. Sure, there are many excellent training programs and materials including online learning packages. But that’s training. Workforce development is MORE than training, as I’ve discussed in this a many previous articles.

From an asset-reliability perspective, we should not expect an asset that was engineered, built, and installed with reliable performance in mind to operate reliably without equally purposeful workforce development. Workforce development with a strategic intent, i.e., competency building, is the people-side of asset reliability.TRR

PUTTING THE WORKFORCE-DEVELOPMENT PIECES TOGETHER

The RAM Review has published numerous discussions (by way of newsletter columns and feature articles) on the topic of training and workforce development. Here’s a list (with links) of several such items under my byline, including the first three installments of the current discussion. . . B.W.

“Strategic Planning For Workforce Development: Rethinking Is Required On All Fronts” (May 8, 2021)

“Strategic Planning For Workforce Development ” (May 2, 2021)

“Make On-Job Training (OJT) Effective and Efficient “(April 22, 2021)

“Develop A Skills-Training & Qualification Checklist” (April 17, 2021)

“Skills-Training Quick Start” (April 5, 2021)

“Ensure ‘On-Job Training’ Is ‘On-Job Learning’” (August 9, 2020)

“A Downside of Online Training” (July 17, 2020)

“Is Online Training All It’s Cracked Up to Be?” (July 12, 2020)

ABOUT THE AUTHOR

Bob Williamson is a long-time contributor to the people-side of the world-class-maintenance and manufacturing body of knowledge across dozens of industry types. His background in maintenance, machine and tool design, and teaching has positioned his work with over 500 companies and plants, facilities, and equipment-oriented organizations. Contact him directly at 512-800-6031 or bwilliamson@theramreview.com.

Tags: reliability, availability, maintenance, RAM, workforce issues, leadership, training and qualification, skills development