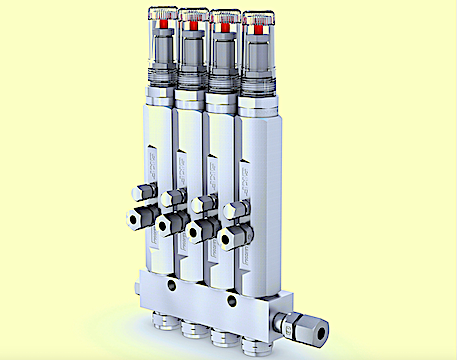

According to SKF, Gothenburg, Sweden and Lansdale, PA, its Lincoln SL-6 grease injector has been designed for ease of use and maintenance in mind. Among other things, the device is said to offer outstanding leak protection and service life, even with harsh EP (extreme pressure) greases. Innovations are focused on supporting a variety of equipment used in harsh environments, including trucks, excavators, and other mining and construction equipment.

The latest addition to SKF’s single-line lubricant injector family, the SL-6 can easily be retrofitted to existing single-line pump systems. Maintenance features include a highly visible red indicator pin, an adjusting screw requiring only basic tools, and a hex-shaped body which maximizes working space, making it easy to handle and work with.

The company notes that for optimally effective lubrication, the device’s vent speed is faster than that of any competitor. This is aided by a daisy-chain effect: as soon as each injector finishes venting, it helps the next one to complete its cycle by consuming grease from the main line.

Improved sealing capabilities reduce the risk of lubricant bypass. In the unlikely event of a failure, the injector’s closed structure channels bypass lubricant to the bearing. Repair is then possible by simply replacing two components.