V-belts serve as the coupling method for a large percentage of equipment in the plant. As I noted in Part I of this two-part series, in my experience, the maintenance of V-belts often has been trivialized.

In that first article (see link below), the importance of proper V-belt tensioning and alignment was emphasized. Here, in Part II, we turn our attention to some simple inspections for V-belts and inventory-management best practices. Again, as mentioned in the first article, some of these suggested practices are applicable to synchronized belts and, to a lesser extent, chains.

Click Here To Read Part I Of This Two-Part Series

V-BELT INSPECTIONS

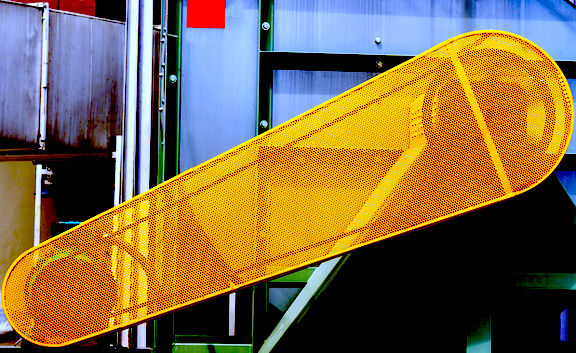

Once these belts have been properly tensioned, there are several run-time inspections that can be accomplished with a simple strobe light. To complete these inspections, safety-protective guarding must have inspection hatches or be screen-type covers, which are usually my preference since they can facilitate cooling of the belts. (NOTE: The life of a V-belt is typically reduced by half for every 10 C-degree increase in temperature. Thus, the cooler the better.)

Once belts are visible, set your strobe light to a frequency that makes them appear to stop. Then look for signs of wear, cracking, or fraying, which indicate that a belt has reached the end of its useful life.

After inspecting the belts themselves, turn your attention to the pulleys to check for slippage percentage. You’ll need the diameter of the pulleys and a strobe light to do this.

First, using the strobe light, determine the rpm of the driving pulley. Multiply that speed by the ratio of the diameters of the driving and driven pulley. For example, if the driving pulley is 10 cm, it’s turning at 1500 rpm, and the driven pulley is 20 cm, the driven pulley should be turning at 750 rpm. If the strobe light reveals that the driven component is turning at 667, you have belt slip of 83 rpm, which, when divided by the theoretical speed of 750 rpm indicates just over 11% slippage. (Ref: see Tim Dunton video link below.)

Plugging the above slippage number into the energy-loss equation discussed in Part I of this series, would show a waste of $3,984 in energy, for which there are no production results. The carbon emissions impact of this increases to just under 47 tons of CO2 emissions and a social cost of carbon (SCC) of just over $2,100. That’s a big deal.

Another trick in strobe-light inspections of systems with multiple V-belts is to mark a line across all of the belts when the machine is stopped, then look at separation of the lines during operation. This method can let you see if the slippage is greater or lesser for any particular belt or belts. At this point, It’s also a good idea to check the pulleys/sheaves for runout (running out of round) with dial indicators. (Ref: see Tim Dunton video link below.)

STORAGE PRACTICES

Another issue that I commonly observe is poor storage of belts in a site’s warehouse or storeroom. The fact is, belts degrade in storage. The rate of that degradation is a function of temperature. To be more precise, the rate of degradation is doubled with every 10 C-degree increase in temperature. Therefore, it’s best to store your V-belts in a cool place.

The common practice of hanging V-belts on a rack can also be problematic: When a new shipment of these belts arrives, storeroom staff typically hang the new additions at the front of the rack. Then, when a work order comes through, they simply pull the required belt(s) from the front of the rack to kit the job. This is called a “last-in, first-out” (LIFO) inventory system. To counter this situation, we need racks that allow storeroom personnel to push new shipments of belts on one side and pull them for kitting from the other side, thus creating a “first-in, first-out” (FIFO) inventory system.

RECAPPING THE BOTTOM LINE

To restate those “words to the wise” from the previous installment of this short series, belt-driven machines and, especially, the V-belts doing the driving, often don’t receive the attention they deserve in asset-management initiatives. In Parts I and II, we’ve focused on some details of that missing attention, including best-practice V-belt tensioning and pulley/sheave alignment, straightforward V-belt inspections, and recommended storage practices that minimize shelf-degradation of belts at a site.

These simple, inexpensive techniques can help an operation increase the reliability of its belt-driven equipment and boost its production uptime. Moreover, the added attention to a site’s V-belts can often be cost-justified on energy savings alone.TRR

Click On The Following Links For The Referenced Tim Dunton Videos

“Strobe Light Belt Slip Test”

https://kvgo.com/Example/belt-tension-slip

“Dial Indicator Runout Inspection”

https://kvgo.com/Example/tightening-pulleys-dials

ABOUT THE AUTHOR

Drew Troyer has 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 250 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees, and is Master’s degree candidate in Environmental Sustainability at Harvard University. Contact him directly at 512-800-6031 or dtroyer@theramreview.com.

Tags: asset management, precision maintenance, reliability, availability, maintenance, RAM, V-belts, belt-driven equipment, maintenance management, energy efficiency, energy savings, sustainable manufacturing