V-belts serve as the coupling method for a large percentage of equipment in the plant. Unfortunately, in my experience, V-belt maintenance is often trivialized. This two-part series focuses on a few precision-maintenance practices that can significantly improve the reliability of your belt-driven equipment, including V-belt tension, pulley/sheave alignment, V-belt inspection and inventory management for V-belts.

Here, in Part I, I we look at tensioning and alignment. Next week, in Part II, we’ll look at V-belt inspections and storage. Note that many of these suggested practices are applicable to synchronized belts and, to a lesser extent, chains.

V-BELT TENSIONING

Proper tension is essential to ensure reliable operation of belt driven equipment. Too much tension places an excessive load on the drive-end bearings of both the driving and driven components. Insufficient tension causes belt slippage which wastes energy and significantly increases the rate at which V-belts wear. If a 100-kW motor is 80% loaded and operates 7,500 hours per year, the system is consuming 60,000 kWh of electricity annually. At a slippage rate of 5% and assuming $0.06/kWh, $1,800 is lost in energy cost for which no productive output is generated. From an environmental perspective, the nonproductive energy waste produces more than 21 metric tons of atmospheric CO2, which carries a social cost of carbon of nearly $950 per year. Energy savings alone will often produce an attractive ROI for precision V-belt maintenance.

Measuring belt tension is relatively simple. While this can be done with spring- or deflection-type tensiometers, I believe sonic tensiometers are faster, easier to use and more accurate.

Sonic tensioners have an acoustic pick-up. When a V-belt is plucked it vibrates and produces an acoustic emission. Each belt has an appropriate frequency : If it’s too loose, the detected frequency will be too low. Conversely, the detected frequency will be too high if a belt is overt-tensioned.

None of the tensioner types are very expensive. Many V-belt manufacturers include them in their catalogs.

The biggest challenge in proper V-belt tensioning is that it involves two interventions. After the belt (or belts) are installed and tensioned, re-tensioning is required after 24 hours. That’s because the belts seat into the pulleys/sheaves during run-in and may relax a bit too much. This re-tensioning task is often omitted, but it’s essential. (Note: when a machine requires multiple belts, it’s best to install them as a matched set.)

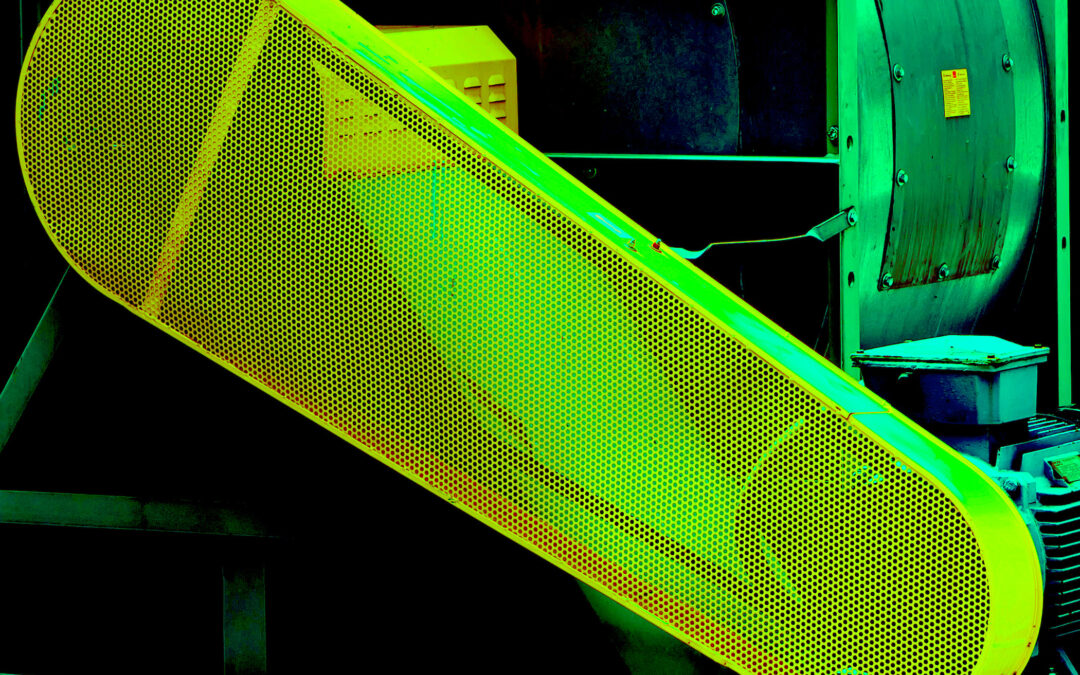

PULLEY/SHEAVE ALIGNMENT

To run properly, the pulleys/sheaves in V-belt-driven equipment must be properly aligned to eliminate horizontal-parallel-offset misalignment, vertical-angular misalignment, vertical-horizontal misalignment, and combination misalignment. While V-belts are a flexible type of coupling, pulley/sheave misalignment increases the rate of wear, puts strain on the bearings, and produces noise and vibration.

As with any alignment, it’s necessary to eliminate any soft foot before starting the alignment procedure. Doing so will ensure the machine is connected solidly to its base and foundation and that the machine, base and foundation function as a single mass. Once soft foot is eliminated, one can quickly complete the alignment using laser-alignment gear that’s specifically designed for pulley/sheave alignment.

That type of laser-alignment gear is also relatively easy to use. Typically, personnel first correct for vertical-angular misalignment, then horizontal misalignment, and, finally, horizontal-parallel-offset misalignment.

WORDS TO THE WISE

Belt-driven equipment, and especially the V-belts themselves, usually don’t get the type of care and feeding they deserve from our asset-management initiatives. With a little bit of attention and a few straightforward tools and techniques, we can increase the reliability of belted equipment and, in the process, boost production uptime. Just as important, we can often cost-justify any related expense on energy savings alone.

Check out next week’s edition of The RAM Review with Part II (the conclusion) of this V-belt series.TRR

ABOUT THE AUTHOR

Drew Troyer has 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 250 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees, and is Master’s degree candidate in Environmental Sustainability at Harvard University. Contact him directly at 512-800-6031 or dtroyer@theramreview.com.

Tags: asset management, precision maintenance, reliability, availability, maintenance, RAM, V-belts, belt-driven equipment, maintenance management, energy efficiency, energy savings, sustainable manufacturing