Developing objective and effective work instruction is a science. The quality of work performed by a maintainer when following a planner’s instruction will vary greatly depending on the objective requirement set within each line of instruction. If direction is vague, e.g., “grease all bearings,” the result will differ considerably based on the maintainer’s knowledge of grease types and the amount to be dispensed into the bearing. Furthermore, if the planner modifies the directive slightly to state, “grease all bearings as required,” the end result will vary even more as the maintainer now has to decide if the bearing actually requires grease. This type of directive is deemed subjective and more of a reminder than instruction.

Lubrication is a science, and we know that mixing lubricants (grease types), over- greasing, under-greasing, or not greasing a bearing at all when needed can have a decided effect on the life of the bearing, the machine it serves, and the consequence of its failure. This is also true for all fluid top-ups/changeouts, filter changes, belts, pulleys, chain and sprocket lubrication, adjustment and changeouts. The items involved in these activities are all crucial engineered consumables that form the basis of most PM work. Their life cycles and performance depends almost entirely on how the maintenance-instruction set is interpreted and carried out. Words do matter.

THE POWER OF OBJECTIVELY WRITTEN CHECKLISTS

In Atul Gawande’s book, The Checklist Manifesto – How To Get Things Right, he describes how the power of instructional language, delivered in a simple, correct checklist format was heralded as the “the biggest clinical invention in thirty years”.

Gawande was tasked by the World Health Organization (WHO) to find a solution that would reduce the amount of post surgical complications and deaths due to surgeries performed on the wrong person or body part, and to post surgical foreign bodies mistakenly left inside patients. In answer to this phenomenon, Gawande implemented a beautifully simple set of hospital checklists now credited for helping save tens of thousands of lives, pain and suffering worldwide over the past 20 plus years. If you ever had to go to an emergency room, how many times did staff members ask your name and what you were in for as they held a checklist?

Gawande didn’t reinvent the wheel when he came up with his objective-checklist system. He modeled it after the Boeing flight-checklist system designed in the 1930s after the fatal crash of the manufacturer’s futuristic Model X299 airplane.

That crash occurred on October 30, 1935, at Wright Patterson Air Force Base, in Dayton, OH, where Boeing was to show off its prototype model X299 to the United States Army Air Corps (USAAC). The event was part of a flight competition between Boeing, Martin, and Douglas aircraft companies. On the line was a contract for delivery of 65 of the winning-model planes. The Boeing X299 was considered a “shoe-in,” as it was bigger, faster, had twice as many engines (4), twice the range of the competitors’ models, and could carry five times the army’s requested payload.

Boeing was relying on their veteran test pilot, Major Ployer P. Hill, to fly the aircraft in a simple circle and flyby maneuver. The plane took off smoothly that morning and rose sharply to 300 feet. At that point, however, it suddenly stalled, lost control, and crashed, killing Hill and a crewman on board. Because the Boeing X299 did not complete the competition requirements, it was disqualified.

Ironically, the initial cause of the X299 crash was thought to be a maintenance issue (some written accounts still make that claim). A subsequent crash investigation, though, revealed the cause to be a simple pilot error: The vastly experienced Hill had simply forgotten to release a new locking mechanism on the rudder and elevator controls that kept the powerful engine draft in check while the plane was on the ground. What happened after the investigation changed the course of the aviation industry and much more.

Normally, such a crash would have resulted in more intensive pilot training. ButBoeing decided to take a new and innovative approach to the problem in which it simplified the training process while simultaneously overcoming any pilot ineptitude and ignorance through development of a simple pilot checklist. Due to the complicated nature of the aircraft, the checklist was to ensure that any future pilot would go through the same exacting preflight, taxiing, takeoff, and landing processes every time the aircraft flew—a checklist procedure so successful that it is modeled almost a century later on every aircraft flying today (planes that are infinitely more complex than those from the 1930s).

Despite the collective disappointment of Boeing and the military, the Army was impressed enough to take another look at the bidding-process rules and found a loophole that allowed it to purchase 13 of X299 aircraft for evaluation purposes. This led to the aircraft seeing military service a short while later, under its new name, the Boeing B-17 “Flying Fortress.” Arguably the greatest bomber in aviation history (almost 13,000 of which were built), the B-17 saw much of its service over Germany and the Far East. It also left a checklist legacy that continues to result in safer flights today.

In both the WHO and USAAC examples, checklists proved they could provide protection against elemental errors that affect the health and life of the checked asset, item, thing, or person. In essence, checklists turn already experts into experts who perform consistently and flawlessly every time!

PM MAINTENANCE CHECKLISTS

In preparing work instructions, there are two distinct methods. The first is for Preventive. Predictive, and Legislated work that is pre-planned and designed to repeat multiple times over a calendar period utilizing the same job plan and instruction set.

When dealing with highly trained individuals such as pilots, surgeons, and maintenance professionals, the idea of working with and adhering to a simple checklist is seen as a difficult sell. According to Gawande, many consider use of such a simple tool to be embarrassing. Overcoming that type of bravado and misguided thinking requires a checklist to be written in a concise manner that does not challenge or insult the professional requirement of the work.

According to Daniel Boorman, the developer of checklists for all of Boeing’s aircraft over 20+ years, the secret of a good one is in how it’s written. Using simple and exact language that is familiar to the profession, a well-designed checklist will fit the flow of work, encourage the user to read each point out loud, and allow the user to detect potential failure prior to occurrence. Boorman advocates use of two types of checklists (“DO-CONFIRM” and “READ-DO”) and recommends choosing the appropriate style for the task.

The DO-CONFIRM checklist allows users to perform work from memory and experience, and then causes them to stop and confirm each work task was carried out. In the READ-DO checklist, which Boorman likens to a recipe, users check off each task as they carry them out.

Maintenance professionals are probably most familiar with the operator checklist written in a DO-CONFIRM style as it is used as a due-diligence check and commonly performed in TPM (Total Productive Maintenance) or 5S environments.

As the skilled workforce diminishes, maintenance departments are increasingly tasked to do more with less. Coping successfully with this transition means applying innovative strategies and tools to ensure work is performed consistently and faster. One such strategy has been the adoption of checklists based on successful healthcare- and aviation formats for maintainers and operators, for planning and work-execution purposes.

Figure 1 shows a typical Generic PM instruction to perform a basic inspection of an industrial air compressor written in a subjective manner most maintainers will recognize.

Fig. 1. Typical air-compressor PM instruction set.

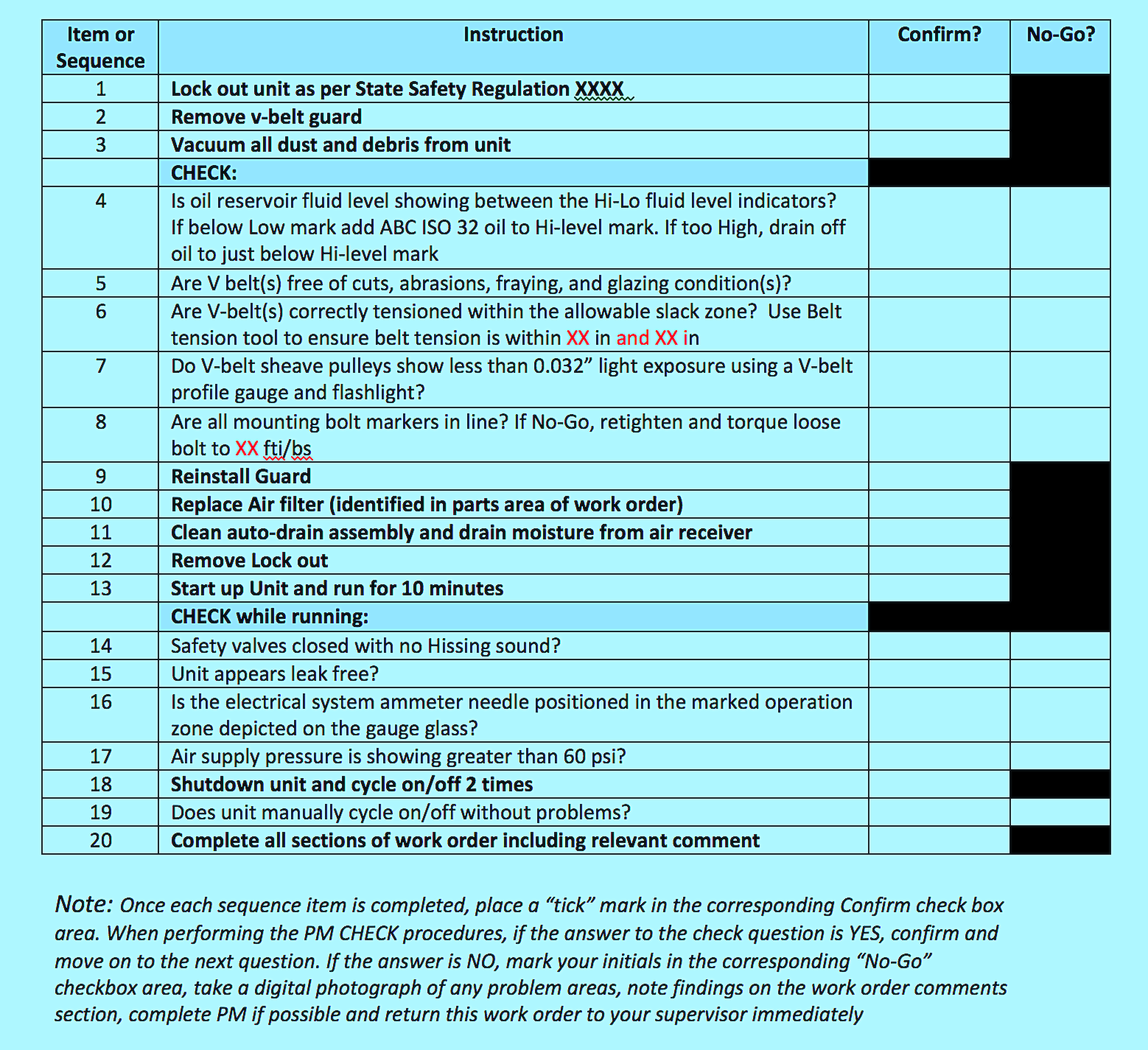

In Fig. 2, we see the same requirements objectively written in a checklist format that is a combination of the DO-CONFIRM style (see instructions shown in bold type with only a confirm check option) and a CHECK-DO style similar to READ-DO (see instructions in non bold type that have both a confirm and a No-Go option). This work-order style delivers more explicit details in what must be checked, and follows a natural workflow or sequenced events.

When there are engineered decisions to be made and adhered to, i.e., lubricant types, air pressure ranges, etc., instructions are specific. Note; the instruction does not tell the maintainer how to remove or install the guard, lubricate or make adjustments, only what to look for to take action.

Whenever a check is required in the CHECK section of the instruction set, a No-Go box is provided to advise the supervisor, planner, and reliability engineer that additional work has already taken place or needs to take place to remedy the problem found. The note text on the bottom of the checklist advises the maintainer of the checklist procedure to follow.

Fig. 2. Revised air-compressor PM instruction set in a checklist format.

Both types of work instructions expect the same result. The difference in how they are written is evident, and it is apparent as to which instruction set will achieve consistent results every time, regardless of which maintainer performs the work. Once a PM work instruction is completed it can be considered for use as a template and modified for similar asset types and renamed. In the Fig. 2 example, the PM can be adjusted for similar but different styles of compressors and renamed as a new template.

NON-PM MAINTENANCE CHECKLISTS

The second type of work order using a checklist format is the non-PM repair, corrective, or demand style, designed for work that’s planned in advance. This type of work is more likely to be unique in format and machine specific. Unlike the PM-style work instruction, a non-PM checklist will be predominantly a DO-CONFIRM style.

Unlike the PM template, the majority of non-PM work is unique, requiring a different work instruction for every job. However, savvy planners get to know what work tends to be similar and/or repetitive and will classify job plans into categories by work type, machine or asset type, location, etc., and build a job-plan library that they can search, review for similar work, and use a previous or similar instruction set as a starting template to build a new work instruction, thereby saving considerable time. Many asset- management-program software packages already have this job library or job bank feature.TRR

Editor’s Note: Click The Following Links for Recent Work-Order-Related Articles by Ken Bannister:

“Maintenance Work Orders: The Request” (April 10, 2020)

“Understanding, Classifying, and Tracking Work” (June 5, 2020)

“Make Work Orders Work” (August, 15, 2020)

“Make Work Orders Work: The Job Plan” (August 20, 2020)

ABOUT THE AUTHOR

Ken Bannister has 40+ years of experience in the RAM industry. For the past 30, he’s been a Managing Partner and Principal Asset Management Consultant with Engtech industries Inc., where he has specialized in helping clients implement best-practice asset-management programs worldwide. A founding member and past director of the Plant Engineering and Maintenance Association of Canada, he is the author of several books, including three on lubrication, one on predictive maintenance, and one on energy reduction strategies, and is currently writing one on planning and scheduling. Contact him directly at 519-469-9173 or kbannister@theramreview.com.

Tags: reliability, maintenance, availability, RAM, work management, work order, job plan, work instruction, checklist, data collection, maintenance workflow, asset management