According to SKF, its HYDROCAM hydraulically operated bolt-tensioning solution can provide far greater accuracy than alternative methods by eliminating uncertainty over the performance and the long-term reliability of couplings. The company notes that damage to bolts and associated structures is avoided, installation is faster, operation of equipment is optimized, and maintenance needs are minimized.

Conventional bolt-tightening methods that depend on torque applied by hand or torque tools can damage threads and flange faces, leading to re-machining and added downtime. Bolts may also become loose over time and need re-tightening. While heat induction offers an alternative method, it requires specialist contractors and additional cost.

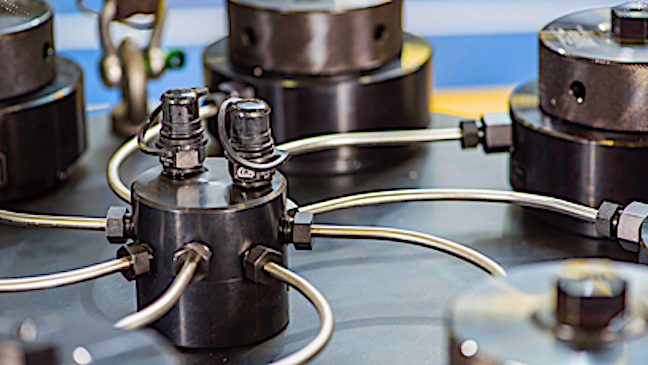

HYDROCAM tensioners are said to overcome those problems by axially stretching bolts and studs, using a pre-determined residual load to create a high-integrity fixing that be mounted and removed quickly and safely without damage. The solution can be supplied as a single tool or incorporated into a multi-tensioner for homogenous tightening. In most applications it’s intended to be reused with multiple fittings, but can also be permanently incorporated into the nut assembly.

Manufactured by Pilgrim, a fully owned SKF company, the HYDROCAM offering comes ready for use with the tensioner unit, power pack and all relevant fittings. The power pack can be hydraulically, electrically or hand operated.