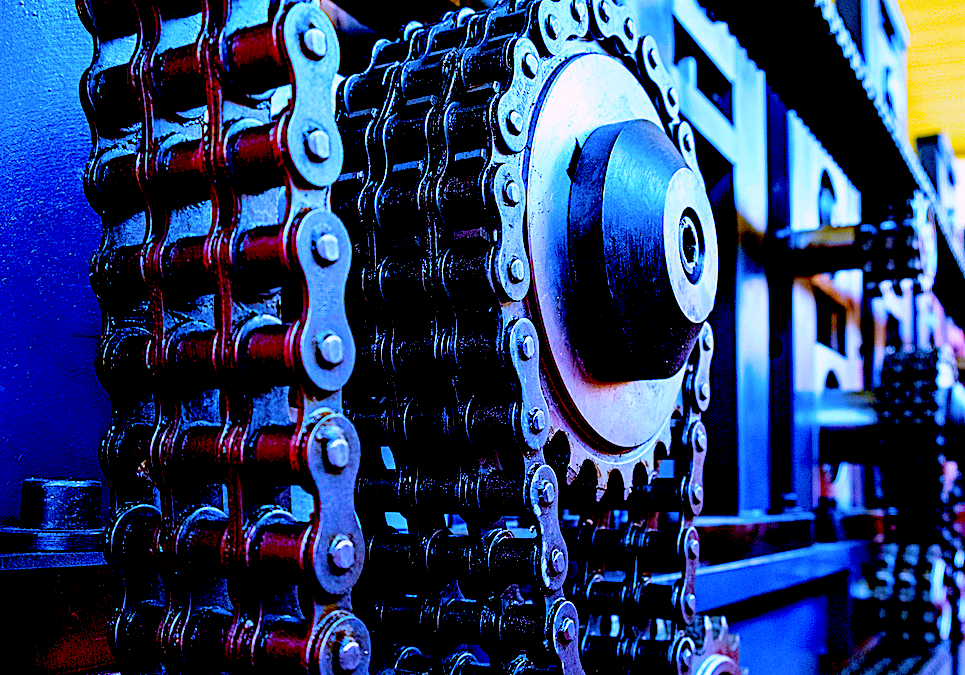

When maintained correctly, a set of roller-chain sprockets will outlive several chain replacements. Unfortunately, many maintenance departments operate under a policy that requires sprockets to be replaced every time the chain is replaced. While this is not necessarily a bad strategy, it will incur needless costs for time to prematurely replace and align sprockets that could still have ample operational life to give.

The key to maximized sprocket life lies in three areas: sprocket quality, setup, and lubrication.

Purchasing agents don’t always have the same agenda as maintainers. Often, they are incentivized or mandated to find component equivalents at lower cost. In the case of sprockets, purchasing an unmatched sprocket from a different manufacturer than the chain may result in a lower-cost, universally sized sprocket that may fit OK, that could have been manufactured from a lower-quality grade steel with non-hardened teeth. The result would be a reduction in the operational life of both sprocket and chain set.

Rule 1: Always purchase the sprocket and chain from the same manufacturer that designed, the components (with the correct steel choices) to operate as a system. If an OEM match is not possible, at a minimum, you must specify hardened teeth.

To ensure maximum chain life, when replacing sprockets, they must be accurately aligned to the shafts and to each other so as to deliver uniform chain load across the face of the sprocket and chain roller. Similar to sheave pulleys, sprockets can be misaligned in the horizontal plane resulting in a “toe in-toe out” angular misalignment; misaligned in both horizontal and vertical planes resulting in offset misalignment; or, in the worst case, a combination of angular and offset misalignment. In all misalignment scenarios, sprockets and chain will wear prematurely, as well as andsuffer from transmission-power losses that will require extra energy to overcome. In addition, to make sure sprockets are balanced correctly, always use the specified key of the correct length.

Rule 2: Always align replaced sprockets before starting for the first time using laser alignment or dial indicator alignment tools.

Chains rollers both roll and slide as they make their way across the sprocket teeth valleys. To reduce wear causing friction between the two mating surfaces lubricant must be introduced externally on to the roller surface of the chain. The delivery method, amount, and type of lubricant used will depend on the transmission design, ambient working condition and environment conditions.

Rule 3: Always consult with your lubrication provider or a lubrication consultant to determine the correct lubricant and delivery method to use.

GAUGING WHEN TO CHANGE SPROCKETS

Because of load, speed and ambient conditions, sprockets will eventually wear to the point of requiring replacement. As stated earlier, if well maintained, a sprocket should outlive several chain replacements.

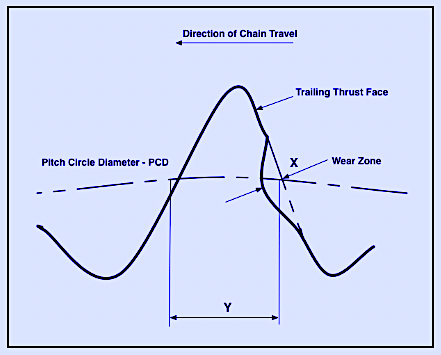

As the chain travels over the sprocket, the chain rollers thrust against the trailing edge of the sprocket tooth, this is called the “thrust face” and it is this face we must regularly examine for wear. In the accompanying sprocket-tooth diagram (below), the curved dotted line represents the pitch circle diameter (PCD). The PCD is easy to physically identify on the sprocket as the tooth above the PCD is usually set at a different face angle that the tooth below the PCD and is often shinier that the rest of the sprocket. The PCD is the contact point of roller and sprocket and the area that we measure and where we look for wear.

Sprocket-tooth wear

Referring to the diagram, note that dimension X represents the actual depth of wear, and dimension Y represents the working width of the tooth at its critical contact or “working” point. Once dimension X reaches 10% of dimension Y, (X = Y / 10) the sprocket is ready for replacement. For example, if dimension Y = 20mm (5/8 inch), the sprocket is optimally replaced when the wear dimension X = 2mm (1/16 inch).

To avoid stopping the machine and physically measuring and calculating the thrust-face wear on each PM inspection, at installation try marking a change indicator mark on the sprocket as follows:

1. Choose a tooth and mark clearly at the base of the tooth with white or yellow paint to identify the change indicator tooth

2. Measure the Y dimension at the PCD

3. Calculate the X dimension

4. Establish the direction of travel

5. On the trailing edge of the marked tooth thrust face where it intersects the PCD, lightly scratch or marker a small reference mark

6. At 90 degrees (perpendicular) to the reference mark, measure in the X dimension and scratch or mark an x or dot

7. Using a center punch and hammer, indent the wear point mark on the sprocket

With the wear point now clearly identified, the actual tooth wear can now be viewed with the equipment running using a simple strobe light. If the chain guard must be removed for inspection, consider reworking the guard with an open “tell tale” inspection port or partial replacement with expanded metal mesh / see through plastic for unobstructed viewing while operational. Alternatively, some higher quality sprockets can now be purchased with tell-tale replacement marks already stamped in place.

Knowing when to replace a sprocket is an element of condition-based maintenance and precision based maintenance. Both are essential in any RAM-based maintenance approach.TRR

ABOUT THE AUTHOR

Ken Bannister has 40+ years of experience in the RAM industry. For the past 30, he’s been a Managing Partner and Principal Asset Management Consultant with Engtech industries Inc., where he has specialized in helping clients implement best-practice asset-management programs worldwide. A founding member and past director of the Plant Engineering and Maintenance Association of Canada, he is the author of several books, including three on lubrication, one on predictive maintenance, and one on energy reduction strategies, and is currently writing one on planning and scheduling. Contact him directly at 519-469-9173 or kbannister@theramreview.com.

Tags: reliability, availability, maintenance, RAM, lubrication, roller chains, chain sprockets, power transmission, conveyors, material handling