From Massimiliano Giffuni

Reliability and Maintenance Specialist

T.A. Cook (tacook.com)

In the process industry, static equipment represents the vast majority of mechanical assets at a manufacturing site. Most of these assets were designed for a roughly 20-year service life. How is it that in some plants, these assets have been reliably performing for over 40 years without replacement? The short answer is inspections. In this article, T.A. Cook’s Massimiliano Giffuni categorizes risk-based inspections as powerful tools that have evolved with technological advancement and can provide major cost savings.

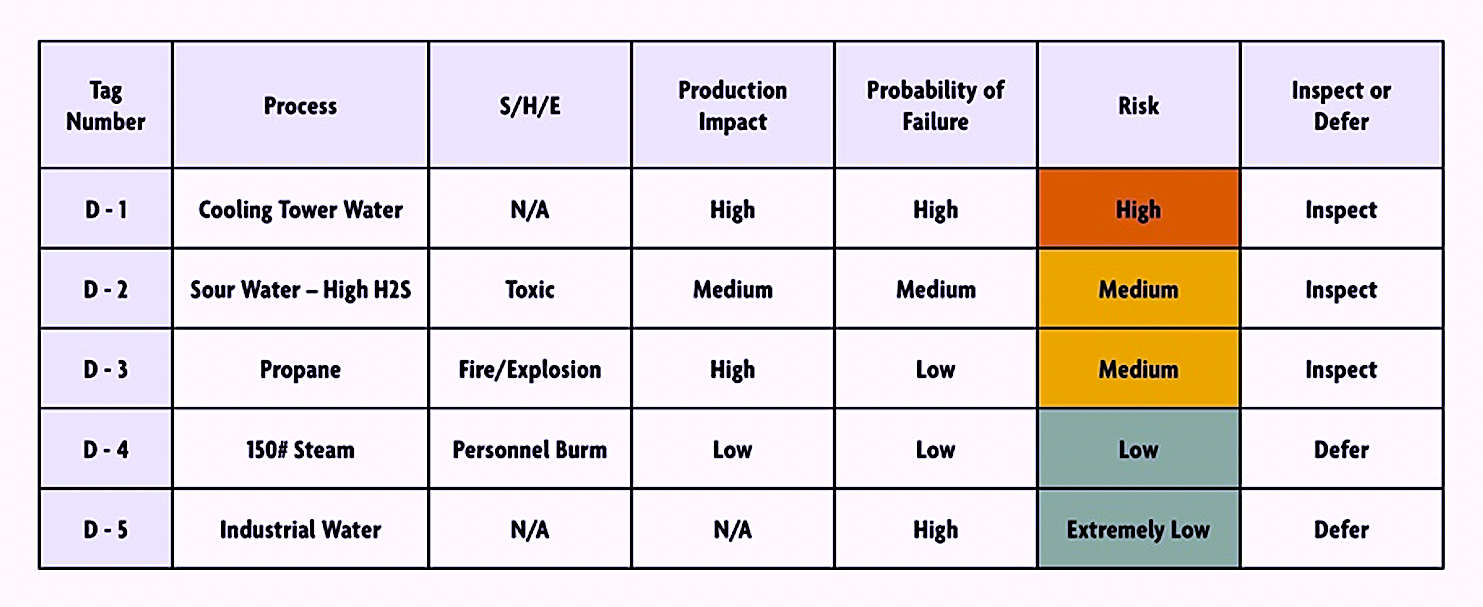

In a hypothetical scenario, a manager has five pressure vessels coming due for their time-based inspection intervals in 2021. Unfortunately, it costs $1.5k per inspection, and the budget is $5k, so what can you do? Utilize the advantage of a risk-based inspection (RBI) approach.

As outlined in the table below, the risk of asset failure is now understood for the five vessels for safety, health, and environmental (S/H/E), and production, in combination with their probability of failure. With the implementation of RBI, the manager can now select the three vessels to prioritize for inspection in 2021 and defer the other two until the budget allows.

In this scenario, the benefits of RBI are clearly understood. However, manufacturing sites do not have just five static vessels to maintain. Rather, they have thousands of equipment items with decades of being in service, including, piping, towers, tanks, and heat exchangers, among others. RBI is a standardized process involving a qualified team of individuals that understand the ways in which the equipment can fail and study the consequences of a failure. By implementing a process that can be replicated across a site, the annual budget can be prioritized to come up with the best return on investment that results in the greatest risk reduction across all of the assets.

Inspection of static equipment by itself does not replace, repair, or build thickness back. If used effectively, inspection can provide an understanding of the condition of the asset and give the owner a chance to become proactive via their risk- management criteria in RBI.

“If used effectively, inspection can provide an understanding of the condition

of the asset and allow the owner a chance to become proactive

via their risk management criteria in RBI.“

In this, owners must not let RBI manage them. Rote application of RBI can become little more than an administratively cumbersome form of time-based inspection. Best use of RBI requires management to have a strong understanding of the RBI methodology and how to get the most out of it. There are several critical items to consider. For starters, program managers must ensure they have the proper data quality and extent to get the most “credit” for their inspection actions. Without the right data, RBI becomes time-based inspection.

Furthermore, managers must have a strong understanding of and involvement in the RBI methodology in order to balance inspection extent (and cost) against the risk-mitigation value that it provides. For example, it is often possible to sufficiently quantify the risk at an acceptable level without going to a full strip-and-inspect approach for all towers and vessels. The trick is to optimize the risk-quantification benefit against the cost of inspection extent.

Overall, inspection of static assets, if managed correctly through RBI, can yield significant costs savings in the form of:

1. Reducing probability of failure via correct inspection effectiveness. With a clear understanding of risk targets and the damage mechanisms present, the user can perform the necessary inspection scope to obtain the effectiveness that results in an acceptable risk reduction. Performing an extensive, rather than targeted inspection is costly and often not necessary.

2. STO Worklist optimization. Online inspections and historical data can provide information to an STO team to confidently remove unnecessary repairs/replacements and internal inspections of assets.

3. Online monitoring for proactive repair/replacement. Inspection can monitor the overall health of the asset and find potential failures before loss of containment scenarios, at the worst, and more ideally, before damage is so extensive as to require replacement rather than repair.

4. Extend traditional time based inspection intervals. Quality inspection data can give the owner of the asset the tools necessary to extend/defer the next inspection. Savings through deferrals can be used elsewhere across the plant for higher-risk activities.

5. Extend the life of the asset. Inspection is often more cost-effective than replacing an asset altogether. Inspection data can raise flags that would allow engineering evaluations to take place to increase the life of the asset, i.e., fitness for service calculations, addition of injection points to mitigate damage-mechanism corrosivity, proactive clamp installations.

“Performing an extensive, rather than targeted inspection

is costly and often not necessary.”

Inspection is a powerful tool used to maintain the reliability of static assets. When utilized correctly with RBI, it not only can reduce the overall risk of a manufacturing plant. It can, at times, yield significant savings. With the right understanding of risk and damage, inspection can provide a story for the owner to move from a corrective mode to a proactive mode, which can lead to safer plant operations and a reduction in maintenance spend.

CLICK HERE FOR MORE INFORMATION ABOUT T.A. COOK

OR VISIT

tacook.com/en/expertise/reliability-management/