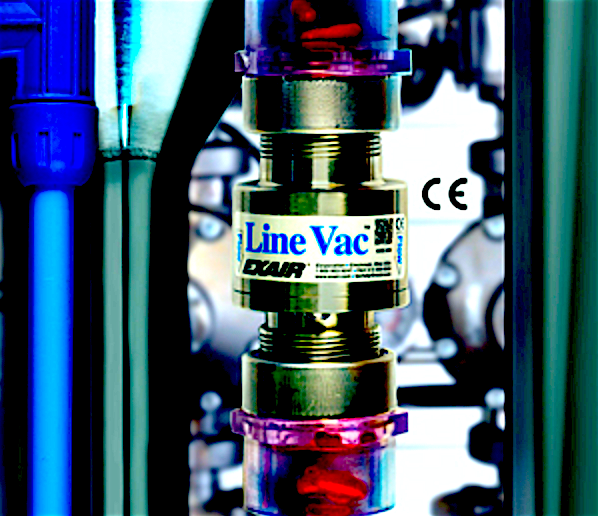

Type 303 Stainless Steel 2-1/2 NPT Threaded Line Vac Air Operated Conveyors from EXAIR, Cincinnati, convert ordinary pipe into a conveying systems. Applications include scrap trim removal, material conveying, part transfer, fiber tensioning, and filling operations.

According to the company, the new offering is appropriate for food, chemical, pharmaceutical, and medical processes, or wet and corrosive environments that require the benefits of 303SS, including high resistance to chemicals and corrosion, the ability to withstand tough temperatures, long service life, and low maintenance. Given its size, this recently released Line Vac model is well suited for moving bigger parts and larger volumes of material over long distance than other versions.

EXAIR’s Threaded Line Vascs work by ejecting a small amount of compressed air to produce a vacuum on one end with high output flows on the other end. Response is said to be instantaneous. Regulating the compressed air pressure provides infinite control of the conveying rate.

The company notes that because these Threaded Line Vacs are designed to attach to standard plumbing pipe couplers, it’s easy to build a complete system using readily available common pipe and fittings.