As maintenance and reliability professionals, we know that the life of bearings and other components will be reduced through misalignment. Still, there’s a question: What is the impact associated with misalignment, meeting basic alignment tolerances, and precision alignment? In this article, we will discuss percentages related to several potential failure points based on data collected from a 1-hp, 1765-rpm, 460V, 1.5 Amp motor operating at several load points. We will then compare this to a much larger motor that’s operating with a misalignment.

The data in each case was collected with an Electrical Signature Analysis (ESA) system that provides a measurement of watts by defect (spectral analysis of power). The percentage of additional greenhouse gas emissions (GHG) above total expected GHG is included in the analysis.

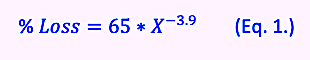

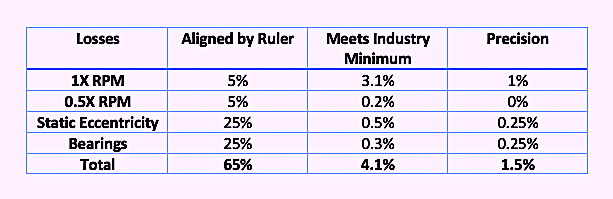

The first thing was to take the test motor and evaluate it after using a ruler to align a direct-drive coupling and measuring the load. The power spectra were measured and losses specific to 0.5 and 1 times rpm, static eccentricity peaks, and bearings were identified in watts lost at the defect frequencies. This work was performed in a lab so that specific defects could be isolated. The second test was alignment performed to minimum industry specifications. The last test performed was to “precision alignment,” which we define for this article as 25% of the tolerances for a standard tolerance. The results of all tests were calculated, as shown in Equation 1, and are presented as percentages in Table I. (The curve for Equation 1 is shown in Fig. 1.)

Table I. Percent Losses From Alignment.

Fig. 1. Percent losses and severity of misalignment:

1=alignment with a ruler; 2=alignment with industry tolerances;

and 3=precision alignment.

When calculating the opportunity to reduce emissions by alignment, it was found that this opportunity follows the energy losses curve exactly as a percentage of the total energy used. For instance, on a larger motor operating on a variable frequency drive, vibration and ESA data identified misalignment and soft foot of a 600-hp, 460V electric motor operating 6,000 hours per year, at 40 Hz, with demand of 90.5 kW. This would translate to 543 Megawatt-hours per year at 0.707 Tons CO2 per MWh, or 384 Tons CO2 per year.

Total losses of the 600-hp motor were detected as 14%, with a majority (11.1%) related to bearing losses. The approach of correcting to a standard alignment would reduce emissions from 14% to approximately 4% (or by 10%). The shift to a precision alignment would reduce those losses to 1.5% (a reduction of 12.5%). In the end, this represents a reduction of 38.4 Tons CO2 per year through a standard alignment, or a reduction of 48 Tons (or an additional 10 Tons of reduced CO2) through precision alignment.

From an energy-impact standpoint, the losses would be a reduction of 54.3 MWh/year with a standard alignment and 67.9 MWh/year with precision alignment. If we consider $0.10/kWh usage, a standard alignment will generate an energy-cost reduction of $5,430 and precision alignment will generate a reduction $6,790. These assumptions, though, don’t take into account the self-feeding losses as components fail and the demand charges.

From a reliability standpoint, the energy losses in each area would feed the degradation of components. This means that the 11.1 kW losses feeding into the bearing stresses in our 600-hp electric motor are translating directly into heat due to friction. The friction is the driver toward failure, as it also degrades lubrication quickly.

Overall, the impact on energy losses in an electric motor varies exponentially with misalignment. Application of precision alignment will greatly improve the overall reliability, energy costs (immediately measurable), and resulting greenhouse-gas emissions. This supports the expectation that a minimum of 14% energy reduction is achievable through the application of a maintenance program. Substantially greater reductions can be accomplished with a precision-maintenance program, which also has the potential to be self-supporting.TRR

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Maintenance and Reliability Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: reliability, availability, maintenance, RAM, electricity, incoming power, electrical-power generation, electric meters, Electrical Signature Analysis, ESA