I frequently write about the tremendous opportunity we have to reduce costs and our environmental footprint by cutting industrial energy consumption. The U.S. Department of Energy (DOE) estimates that for most industries, energy consumption and associated greenhouse gas (GHG) emission can be reduced by 20% to 25% by simply implementing existing state-of-the-art technology. Nowhere is this more evident than in compressed-air systems.

According to estimates from DOE, a typical industrial site uses 10% of its electricity to operate compressed-air systems. There’s significant energy waste in this situation. Let’s explore an energy and GHG recovery plan for the compressed-air systems at your facility..

The first step is to find and fix your leaks, and for good reason: From 20% to 30% of a typical plant’s compressed air is lost to leaks. Once upon a time, leaks were tough to find. Back then, they had to become so large that they could be heard by the unassisted human ear. Or personnel had to slowly go through plants with spray bottles of soapy water to hunt them down, a very laborious process. Those days are long past.

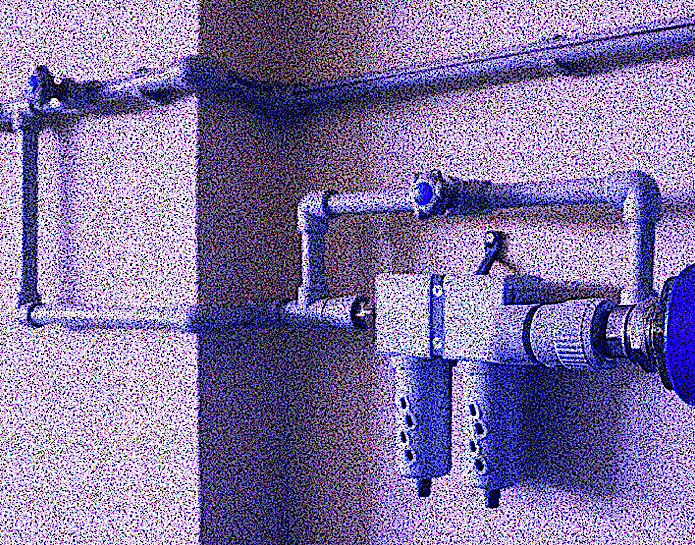

Small leaks produce turbulence, making them detectable in the ultrasonic range. A technician armed with an airborne-ultrasonic-acoustic-emission detector can quickly locate those leaks and fix them as found (often loose connectors), or tag and log them for future repair. Reclaiming the energy lost to leaks is easy money and should be your first step. But don’t stop there.

Variable Frequency Drives (VFDs) offer another opportunity to reduce energy consumption. With a VFD, you control the motor’s speed and can match the supply of compressed air to the demand and avoid waste. On the use side, install regulators so that you’re not oversupplying air to pneumatic tools, cylinders, and actuators.

Also, make sure that you properly size and maintain compressed-air filters. If those filters are undersized and/or full, energy will be wasted in the form of pressure drop and frictional losses.

Dedicate some of the savings from the easy projects, such as fixing leaks, to reconsider your compressed-air delivery-systems. Things such as undersized pipes and hoses and sharp bends in the delivery system introduce frictional losses. Size piping to ensure you have laminar flow with a low Reynolds number (<2000 – less is best) in straight lines of pipe or hose and sharp turns are avoided. The turbulence created in narrow passageways and sharp turns results in energy being converted to heat via friction.

In round numbers, a 100-kW air compressor operating at 80% load for 8,000 hours a year, with a 95%-efficient motor consumes about 674,000 kW of electricity per year. Assuming an energy cost $0.05 per kWh, the electric bill for that one compressor would be $33,684/year. Reducing this cost by 25%, as the DOE suggests, would save $8,421/year, and for very little investment. If your site had 10 of these compressors…well, you can do the math.

On a related note, those types of energy savings would reduce a plant’s carbon impact by about 120 metric tons (MTs). The prevailing view is that the social cost of carbon (SCC) is about $50 per MT. Eliminating leaks and inefficiencies for the air compressor in our example would yield nearly $6,000/year in reduced SCC impacts. Plus, maintenance costs would be reduced, due to reduced strain, wear, and tear on the plant’s equipment systems.

So, what’s stopping you? Implement a sprint project to get your air-compressor reliability under control today.TRR

ABOUT THE AUTHOR

Drew Troyer has over 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 300 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees. Drew, who also earned a Master’s degree in Environmental Sustainability from Harvard University, is very passionate about sustainable manufacturing. Contact him at 512-800-6031, or email dtroyer@theramreview.com.

Tags: reliability, availability, maintenance, RAM, compressed-air systems, air compressors, U.S. Dept. of Energy, DOE, energy efficiency, greenshouse gas, GHG, electric motors, variable-frequency drives, VFDs