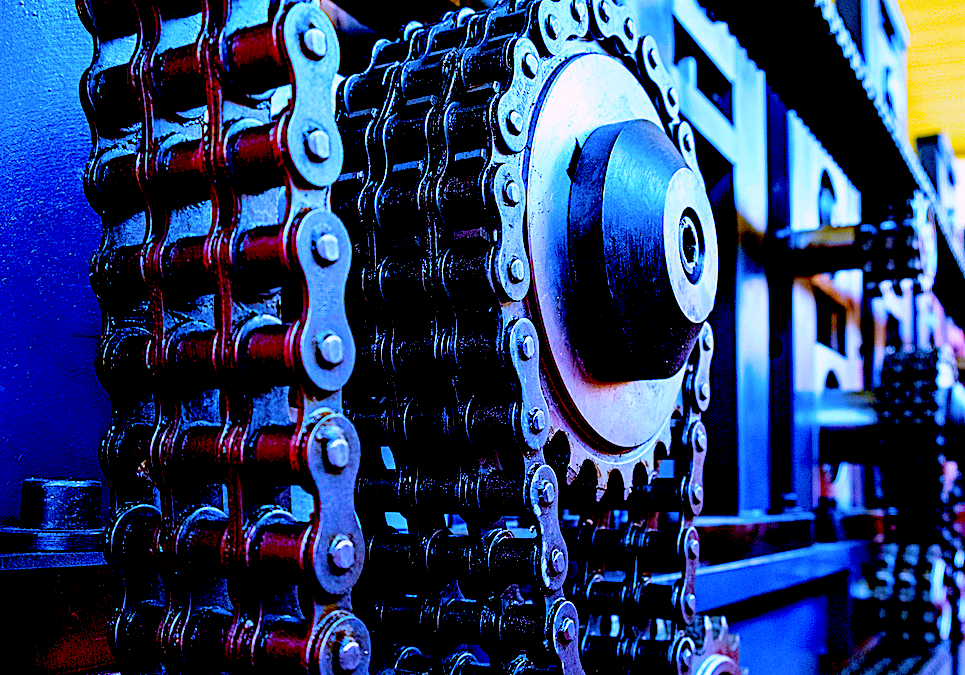

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 30, 2020 | RAM Tools & Methods

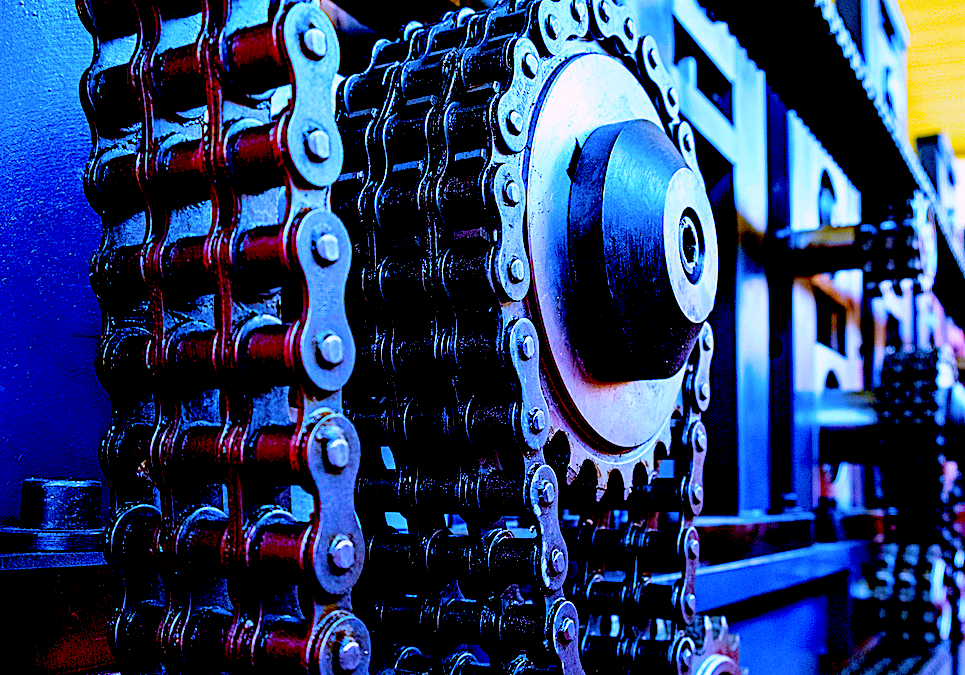

When maintained correctly, a set of roller-chain sprockets will outlive several chain replacements. Unfortunately, many maintenance departments operate under a policy that requires sprockets to be replaced every time the chain is replaced. While this is not...

by Tim Dunton, CMRP, CMRT | Jul 25, 2020 | Asset Management, RAM Tools & Methods

Many reliability practitioners think of precision maintenance as merely “maintaining machines the right way.” In their view, as long as technicians are trained and given the latest shiny tools, they will be successful. While training and tools are...

by Heinz Bloch, P.E., Editor | Jul 18, 2020 | RAM Tools & Methods, The Bloch Files

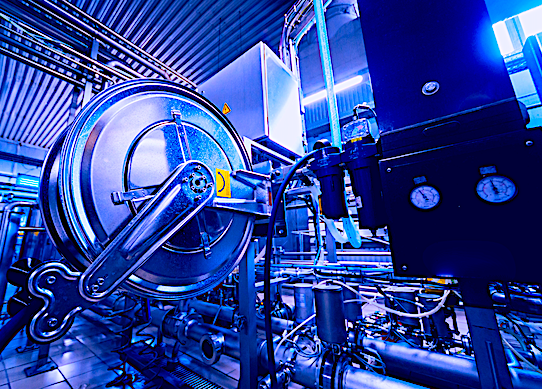

My article for The RAM Review last week (July 13, 2020) focused on “C.A.R.E.,” an acronym that stands for “Clear Direction and Support,” “Adequate Detail,” “Recognition and Reward,” and “Empathy.” As I noted...

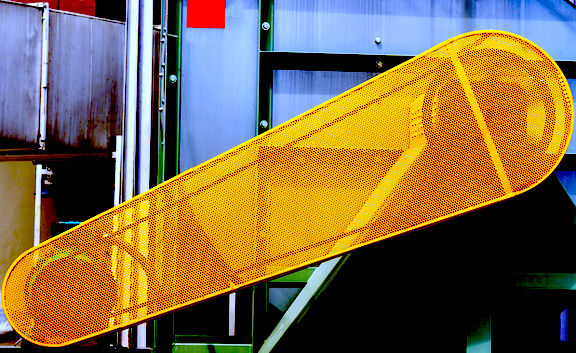

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 17, 2020 | RAM Tools & Methods

A maintainer’s personal spare time has always been a precious commodity. Most often, that time is divided into family responsibilities and homework assignments. And, if we’re re lucky, it’s balanced out with a bit relaxation time for pursuit of hobbies,...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jul 4, 2020 | Plant Operations, RAM Tools & Methods

Consider the following remarks from the real world. Do they sound familiar or, more precisely, have you heard similar comments around your operations (or a client’s)? “Recently, our top executives announced that our cost of manufacturing still wasn’t what it...

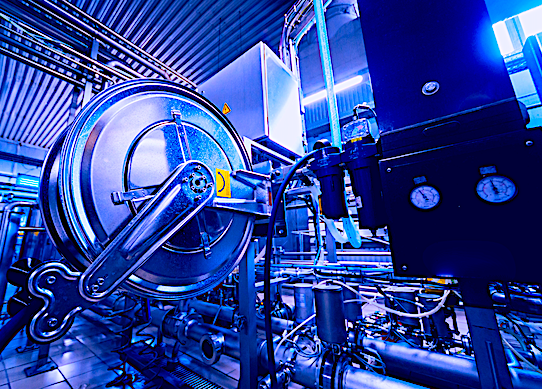

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jul 3, 2020 | Lubrication Corner, RAM Tools & Methods

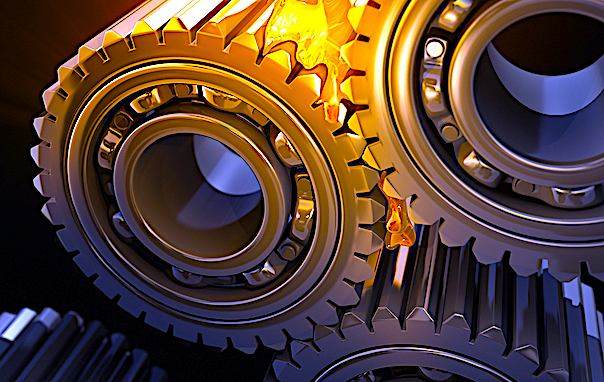

In the maintenance world, tools are indispensible in that they allow a maintainer to perform and complete work in a safe, consistent, and efficient manner (see article “Using the Right Tool for the Job”). When we think of tools, most will immediately picture a...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Jun 27, 2020 | Asset Management, RAM Tools & Methods

Technology has changed behavior patterns in industrial operations tremendously. Some changes have been good and others not so good. As an example of the latter, I’ve observed that managers and engineers spend the majority of their time on computers and in meetings,...

by Bob Williamson, CMRP, CPMM, MIAM, Editor | Jun 26, 2020 | Plant Operations, RAM Tools & Methods

“Maintenance” alone cannot make equipment and processes reliable. Often, a maintenance department is reacting to problems caused by decisions and/or actions of other departments. Further, in high-reliability plants, the maintenance department is NOT a “supplier” of...

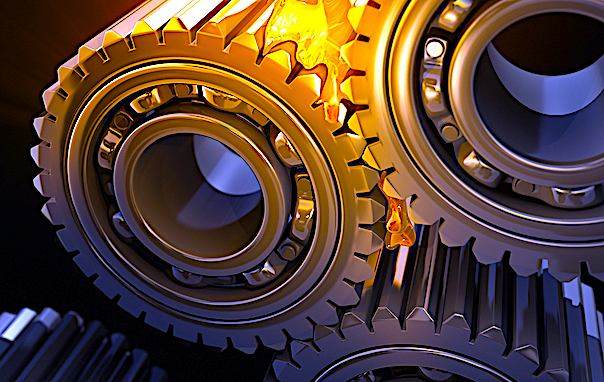

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Jun 20, 2020 | RAM Tools & Methods, The Sustainable Plant

V-belts serve as the coupling method for a large percentage of equipment in the plant. As I noted in Part I of this two-part series, in my experience, the maintenance of V-belts often has been trivialized. In that first article (see link below), the importance of...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jun 19, 2020 | Maintenance Management, RAM Tools & Methods

Every good tradesperson knows that use of incorrect and inferior quality tools can result in inferior work. That said, no definitive study has been performed on resulting costs (the direct costs incurred through broken tools and broken fasteners, and indirect costs...