Incorrect settings in a variable-frequency-drive (VFD) application have an impact on the windings of an electric motor. If a drive is not set correctly, or not tuned when straight volts/hertz settings aren’t used, stresses occur between the turns in a winding. In some cases, this will appear as small Partial Discharges (PD), and in others it can manifest as increased leakage between turns. When these conditions occur, they introduce small current discharges that affect the air-gap magnetic field of the motor. This article focuses on the use of Electrical Signature Analysis (ESA) to detect the problem.

RESEARCH OVER TIME

A published study on this topic, was presented at the 2020 Institute of Electrical and Electronics Engineers (IEEE) Electrical Insulation Conference, under the title, “Evaluation of Stator and Rotor Inter-turn Stress with Electrical Signature Analysis in Variable Frequency Drive and Wind Generator Applications.” [1] That study was pursued following prior research performed on discharges in a vacuum. [ 2] Discharges associated with windings evaluated by an Electrom iTIGII PD surge tester (iTIGII) in vacuum-chamber testing were observed. Then a field-study was performed on windings in 10 flywheel storage motor-generators running in near-vacuum, using both the iTIGII and an Electrical Signature Analyzer (ESA). Where there were signs of PD in six of the ten 0.5 MW flywheel storage machines, a specific signature associated with “winding shorts” was observed. A review identified some issues with both the settings on the VFDs and the filters associated with the machines.

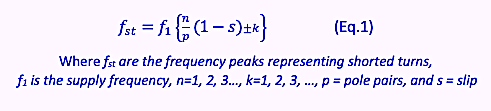

The discussion of the signatures associated with an inter-turn short and related research has been around for some time. The first identification of this type of short in an IEEE paper came from General Electric in 1997 [3], which noted negative sequence currents as shorts developed in a motor on a VFD. The first publication of the associated formula for detection was by Joksimovic and Penman, in Oct. 2000, in an IEEE paper, “The Detection of Inter-Turn Short Circuits in the Stator Windings of Operating Motors” [4] that introduced the spectral equation below (Eq. 1).

Historically, work related to this issue was primarily performed by university and corporate researchers in laboratory environments with induced faults, as it had been determined that winding shorts would occur too rapidly for detection prior to failure. And, while a literature search turned up a number of such studies being conducted in the years following 1997, none looked beyond actual arc-shorts between conductors.

Following the observations on the flywheel study, we performed a review of historical data related to machines that had experienced both bearing-discharge failures (bearing fluting) and winding faults on VFD applications and identified a correlation, which justified additional research.

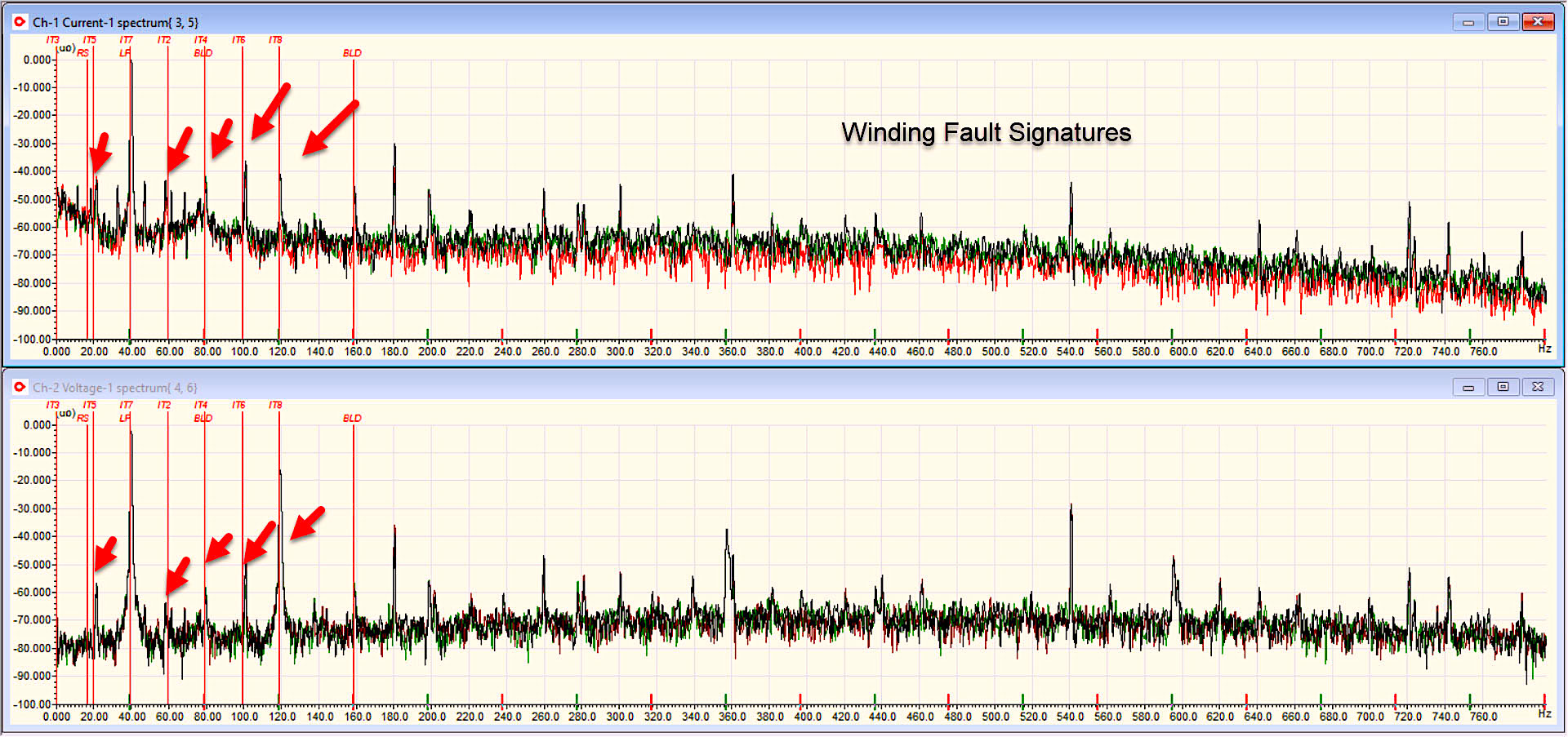

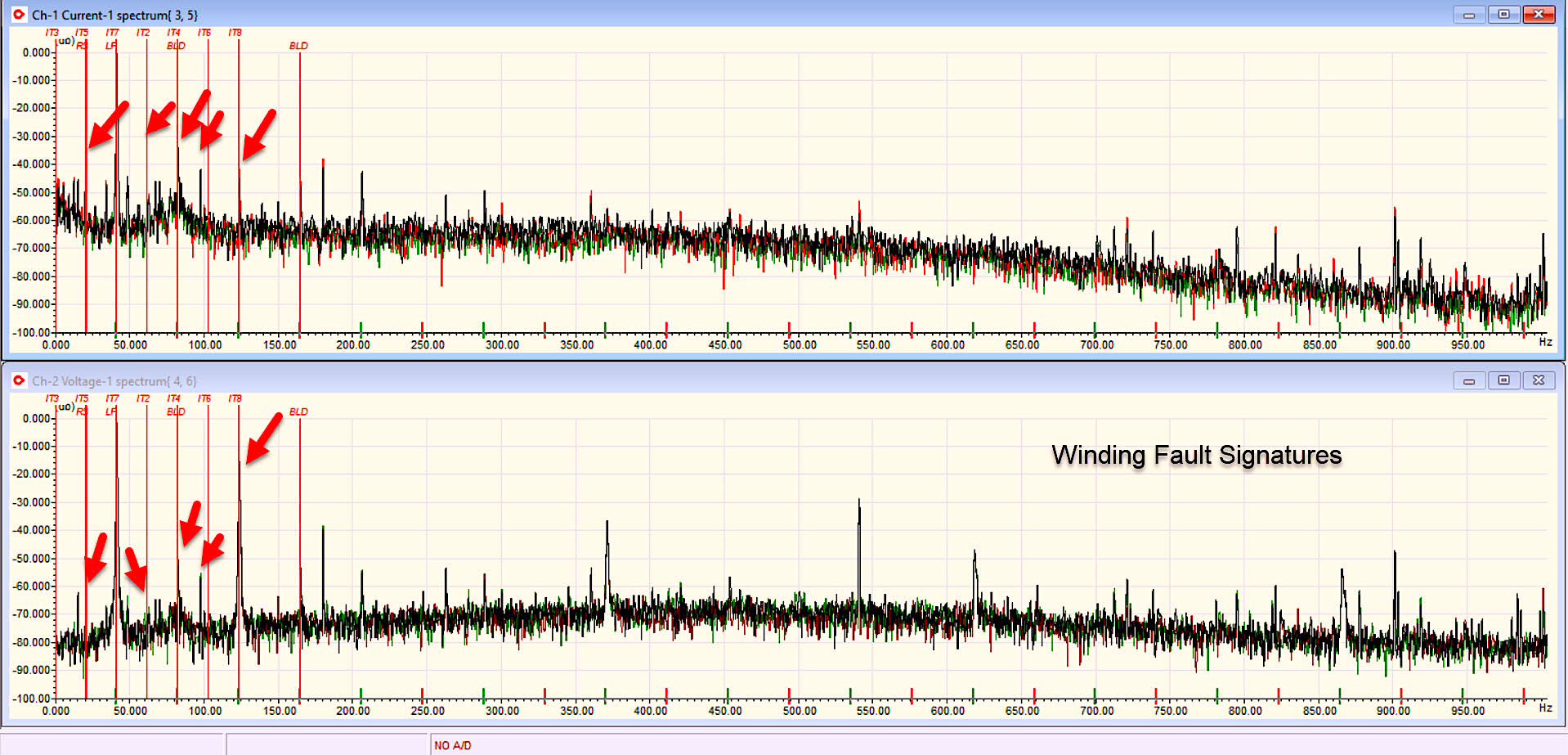

The next step was the identification of existing conditions in three 600 hp, 460 Volt, 4-pole electric motors. Initial testing results showed as Fig. 1, which were also close to several bearing frequencies, and definite calculated winding stress peaks were found. It was determined that if we had not been looking for these frequencies, they might have been erroneously identified as being associated with the bearing peaks. The drives were then tuned correctly, which led to results like those shown in Fig. 2.

Fig. 1. Winding Stress Peaks associated with drive

that was set incorrectly (operating at 40 Hz).

Fig. 2. Winding Stress Peaks decreased significantly in same

operating conditions after drive was set correctly (40 Hz).

The study was then performed on a larger population of motors (67 units), ranging in size from 10 hp to 300 hp. Nineteen of those motors were found to have the winding-stress signature. All 19 had incorrect drive settings. The remaining motors (48), which had correct drive settings, did not appear to have any issues. Changing the drive settings eliminated, or significantly reduced, the stress signatures. (Note: The 2020 IEEE paper coming out of that study reflected the first technical use of the term “winding stress” to describe this class of early detection.)

CONCLUSION

The importance of distinguishing the previously described “winding short” signature in ESA as “winding stress” cannot be overstated. When reviewing data related to the stator, a winding-stress signature can identify the severity of a defect. For example, slot sparking in high-voltage motors will also show as a winding-stress defect, which means a signature related to the stator winding and a winding-stress signature would indicate stator coil movement with sparking.TRR

REFERENCES

1. H. W. Penrose, “Evaluation of Stator and Rotor Interturn Stress with Electrical Signature Analysis in Variable Frequency Drive and Wind Generator Applications,” 2020 IEEE Electrical Insulation Conference (EIC), Knoxville, TN, USA, 2020, pp. 274-277, doi: 10.1109/EIC47619.2020.9158738.

2. H. W. Penrose and M. B. Dreisilker, “Evaluation of Offline Partial Discharge in Vacuum Environments,” 2019 IEEE Electrical Insulation Conference (EIC), Calgary, AB, Canada, 2019, pp. 364-367, doi: 10.1109/EIC43217.2019.9046618.

3. G. B. Kliman, W. J. Premerlani, B. Yazici, R. A. Koegl and J. Mazereeuw, “Sensorless, online motor diagnostics,” in IEEE Computer Applications in Power, vol. 10, no. 2, pp. 39-43, April 1997, doi: 10.1109/67.582451.

4. G. M. Joksimovic and J. Penman, “The detection of inter-turn short circuits in the stator windings of operating motors,” in IEEE Transactions on Industrial Electronics, vol. 47, no. 5, pp. 1078-1084, Oct. 2000, doi: 10.1109/41.873216.

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: reliability, availability, maintenance, RAM, electric motors, drives, motor testing, Electrical Signature Analysis, ESA