As wildfires rage in the Western United States and storms strike coastal regions of the Atlantic and Gulf of Mexico with greater frequency and ferocity, human activity-induced climate change has become an increasingly common conversation topic. Of great importance to readers of The RAM Review is the simple fact that consumers are preferentially purchasing from sustainable companies, and investors are preferentially backing sustainable companies. Sustainability is good business, but you need a game plan. Establishing a current baseline for sustainable manufacturing is a move in the right direction.

In my July 19, 2020, article for The RAM Review, I introduced readers to ASTM E3096 –“Standard Guide for Definition, Selection, and Organization of Key Performance Indicators for Environmental Aspects of Manufacturing Processes.” Here, I dive deeper and challenge you to begin defining your organization’s current state of key performance indicators (KPIs) for sustainable manufacturing. By doing so, you can begin to identify opportunities for improvement.

GUIDANCE ON GETTING STARTED

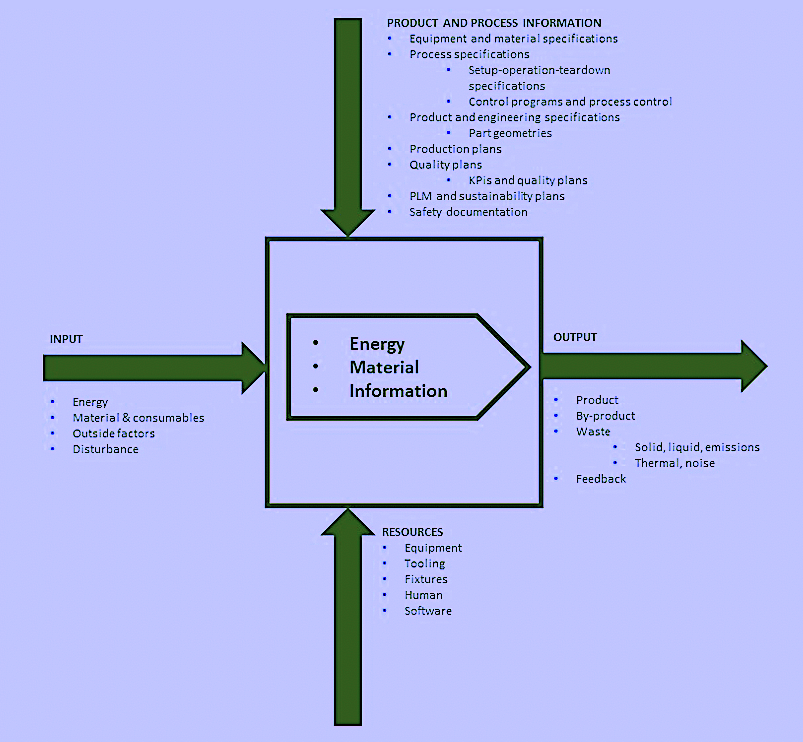

ASTM E2986 – “Standard Guide for Evaluation of Environmental Aspects of Sustainability of Manufacturing Processes,” offers an excellent guideline for assessing the environmental impact of a manufacturing or process plant. The focus is on materials use, reuse, and recycling; water use, treatment, and effluent; and, of course, energy consumption. ASTM E3012 – “Standard Guide for Characterizing Environmental Aspects of Manufacturing Processes” does a great job at characterizing these material flows in a simple graphic (Fig. 1). Engineers should be able to characterize the material, energy, and water flows for their plants by utilizing a similar simple graphic. This a is great way to get started with the analysis of your sources and use of materials, water, and energy because it puts a frame around things.

Fig. 1. A simple material, energy, and water flow graphic per ASTM E3012-20.

CREATING A SUSTAINABILITY KPI

Once the general material flows are defined, ASTM E3096 becomes your tool of choice. This standard provides the guidelines for quantifying and attributing these material flows on a per unit of production basis so that you can monitor performance. When undertaking any improvement initiative, it’s sensible to clearly define the purpose for any proposed change and to define what constitutes success. The KPIs selected to reflect change help by objectifying performance, i.e., we can define our baseline performance and mark our progress along the improvement route. Additionally, KPIs facilitate communication about what we’re doing, why we’re doing it, and how far we’ve progressed.

I really like the structure and flow of ASTM E3096. It provides clear guidance on how to create a system of KPIs for sustainable manufacturing and provides some very concrete examples, many of which will be applicable to most manufacturing and processing plants. At a minimum, each KPI must reflect some aspect of environmental performance in the plant (usually related to energy, materials, and/or water. Your KPIs also must be operational, quantitative, and easy to understand.

As is the case with any metric or KPI, sustainable manufacturing KPIs must have a clear definition and standardization of units. For example, energy may be defined in kilojoules (kJ), water in liters, solid material in kilograms (kg), emissions to air in kg or metric tons (mt), and so on. I suggest that you utilize standard international (SI) units as much as possible when creating sustainable manufacturing KPIs to simplify interchangeability and unit conversion.

ASTM E3096 suggests that when creating a sustainable manufacturing KPI it should support an objective as defined in ASTM 2986; section 5.2. In theory, I prefer setting specific objectives and then creating metrics that will support decisions in pursuit of those objectives as a serial process. In practice, however, I often find the reverse is more productive. Sometimes, it’s easier to start measuring different aspects of performance that you know to be related to the overarching mission, and then clarify your specific goals as you clarify the definition of your KPIs. Indeed, while ASTM E2986; section 5.2 calls for setting goals, the next section (5.3) clearly states the need to define your performance indicators, which is the focus of ASTM E3096. As you set forth to establish your sustainable manufacturing policies and plans per the ASTM standards, it’s a good idea to have ASTM E2986, ASTM E3096, and ASTM E3012 in front of you the entire time. That’s because each addresses different aspects of the more global initiative.

KPI PRIORITZING, RANKING, WEIGHTING

Section 5.4 of ASTM E3096 calls for prioritizing, ranking and weighting the KPIs relative to your goals. The standard calls for expert opinion in the ranking of these elements. Expert opinions can help, but I would rather allow for an environmental life-cycle assessment (LCA) of inventories and impacts to drive this decision. This process is guided by ISO14040 “Environmental management – Life cycle assessment – Principles and framework,” and ISO 14044 “Environmental management – Life cycle assessment – Requirements and guidelines.” I briefly assessed these ISO standards for the LCA process as it pertains to ISO 55000 and asset management in my Sept. 5, 2020, article for The RAM Review. The LCA process enables us to objectively define the environmental impacts associated with a product and/or a process based upon a standardized library of impacts. That, in turn objectifies the process of assigning weights and priorities to your sustainable manufacturing KPIs.

SUSTAINABILITY KPI EXAMPLES

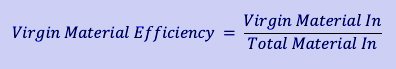

The Appendix of ASTM E3096 provides some nice example KPIs to get you started. For instance, the standard defines a metrics for virgin material as a function of total material. While not comprehensive, this metric provides some insight into our objective of reusing and recycling material.

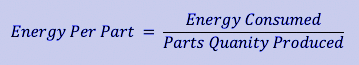

Another KPI example provided in the ASTM E3096 standard is energy per part produced, which could be converted to any unit of production, such as metric tons. The equation in the standard is given as:

As you can see, this KPI can be a bit tricky if your plant utilizes multiple energy sources. Electricity is pretty simple: We would just use kilo-Watt hours (kWh). If, however, the process also utilizes, say, natural gas, you’ll need to convert, as I’ve previously cautioned, to standardized units. For example, a cubic meter of natural gas equals 8.816 kWh of electricity and 31,716 kJ of energy because one kWh of electricity equals 3,600 kJ of energy. Reducing to a single unit for measuring energy usage when setting up the metrics is probably your best bet.

These are just some examples of potential sustainability KPIs discussed in ASTM E3096. There is so much more to discuss pertaining to the ASTM standards for sustainable manufacturing. These standards are being improved and expanded upon by the ASTM E60.13 technical committee, of which I’m a member.

THE BOTTOM LINE

Rest assured that we’ll continue to explore sustainable manufacturing in future issues of The RAM Review, and I’ll be sure to keep you up-to-date on a wide range of topics related to it. After all, sustainability performance is driving investment decisions and consumer purchasing decisions at a rapidly growing pace. In addition, organizations with the best sustainability performance tend to be more profitable because they’re more energy-efficient and utilize materials more sparingly. My advice: Don’t get caught playing catch-up in the pursuit of sustainability at your plant. Act now!TRR

ABOUT THE AUTHOR

Drew Troyer has 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 250 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees, and is Master’s degree candidate in Environmental Sustainability at Harvard University. Contact him directly at 512-800-6031 or dtroyer@theramreview.com.

Tags: reliability, availability, maintenance, RAM, environmental sustainability, sustainable manufacturing, ASTM, energy efficiency, safety, climate change, sustainable investment, sustainability performance, key performance indicators, KPIs, ASTM E60.13 technical committee, ISO 55000, ISO 14000, ASTM E3096, ASTM E2986, ASTM E3012-20