by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 23, 2021 | Asset Management, RAM Tools & Methods

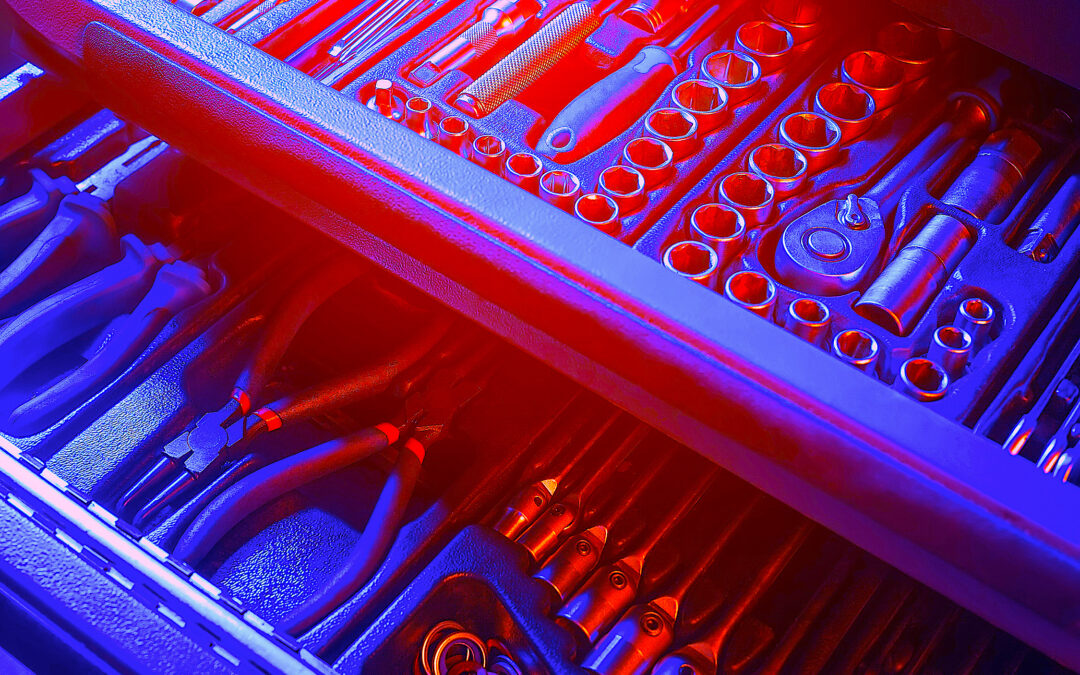

In the maintenance world, there are two types of inventory that must be managed. The first, which most people know as Maintenance, Repair and Overhaul (MRO), consists of spare or replacement parts. These items can be held on site in specialized physical inventory...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 16, 2021 | Lubrication Corner, Maintenance Management

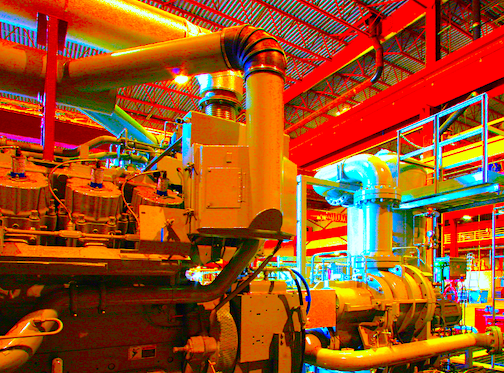

A manufacturing client recently asked me a seemingly difficult question: Does a simple, universal, inexpensive, easy-to-implement maintenance strategy that’s capable of substantially increasing machine reliability and availability actually exist? My answer...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 10, 2021 | Newsletter Column, RAM Tools & Methods

While driving my car several weeks ago, I felt a slight vibration in the steering wheel. I initially thought it might be due to snow buildup in one of the front wheels, but a visual check revealed clean wheels. During my next drive, though, the vibration became...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Jan 3, 2021 | Asset Management, RAM Tools & Methods

A little over a year ago (Nov. 18, 2019), I wrote a newsletter column titled, “The Most Wonderful Time of Year” (see link below). In it, I highlighted how maintenance departments often go on shopping sprees with unspent budget dollars at the end of the...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Dec 19, 2020 | Asset Management, Lubrication Corner

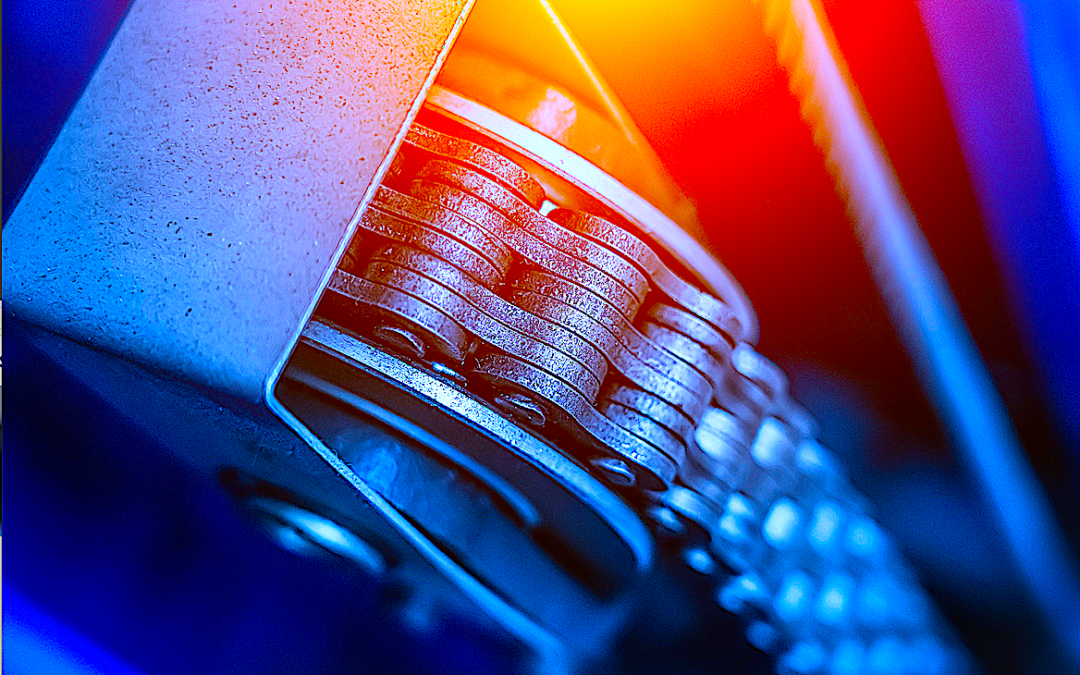

In my Dec. 12, 2020, article, “ Improve Hydraulic System Reliability For Just Pennies A Day” (see link below), I used the term “creep to failure.” It describes mechanical systems that continue to work, albeit inefficiently, for long periods of time,...

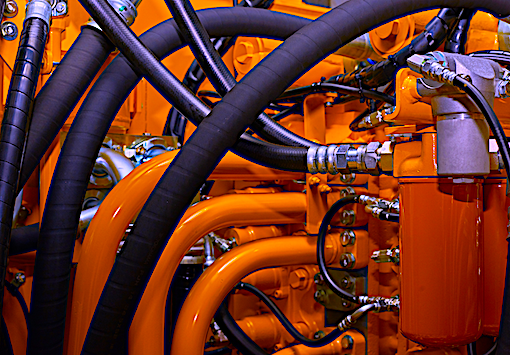

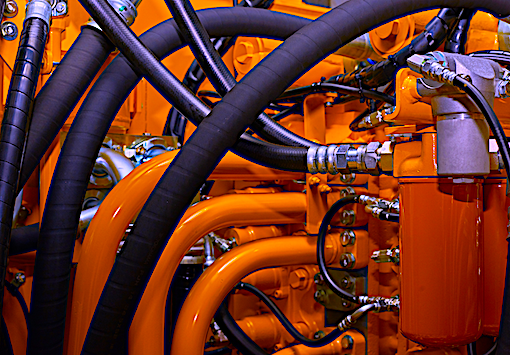

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Dec 12, 2020 | Lubrication Corner, Maintenance Management

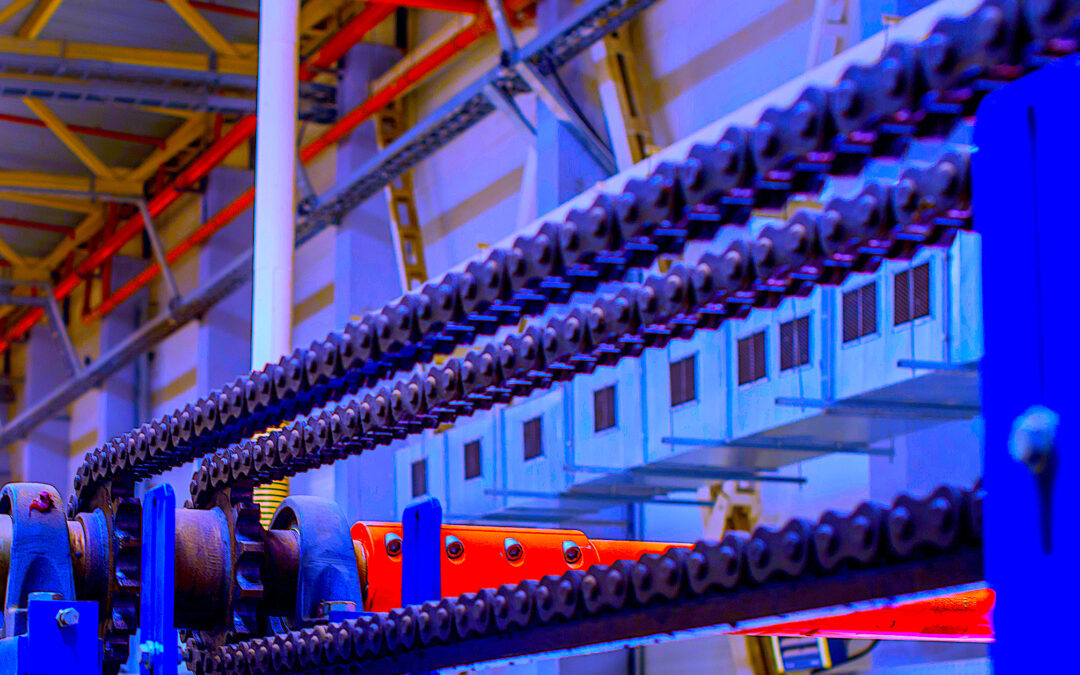

Despite their complexity, hydraulic systems are forgiving in nature. In most cases, they can perform well for a long time before any major or catastrophic failure occurs. Unfortunately, this “creep to failure” quality can promote apathy in production and maintenance...

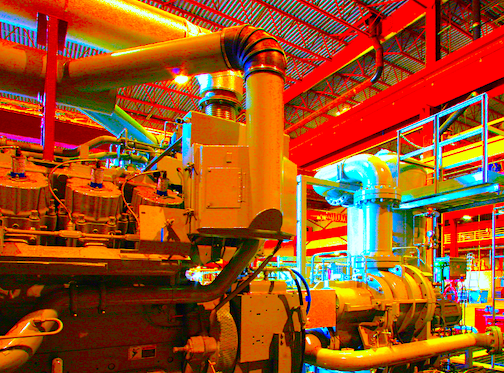

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Dec 6, 2020 | Newsletter Column, Plant Operations

Industrial workplaces, for the most part, are reasonably well-lit areas with lighting that allows unhindered movement throughout open plant-floor spaces. In closed-room environments, fixed ceiling lighting originally specified and installed by the building contractor...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 28, 2020 | Asset Management, RAM Tools & Methods

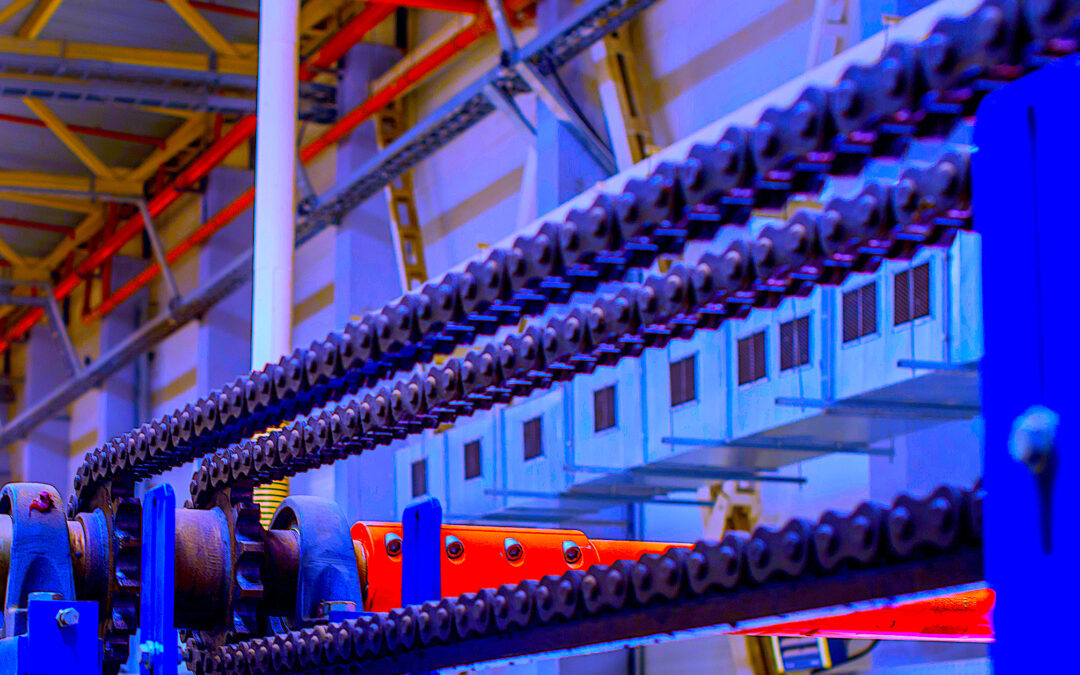

Once a piece of equipment or a building has been built, installed, and commissioned, it is customary to hand over the caretaker keys to the maintenance department. Regrettably, in many organizations, this ends up being the first opportunity that maintenance team...

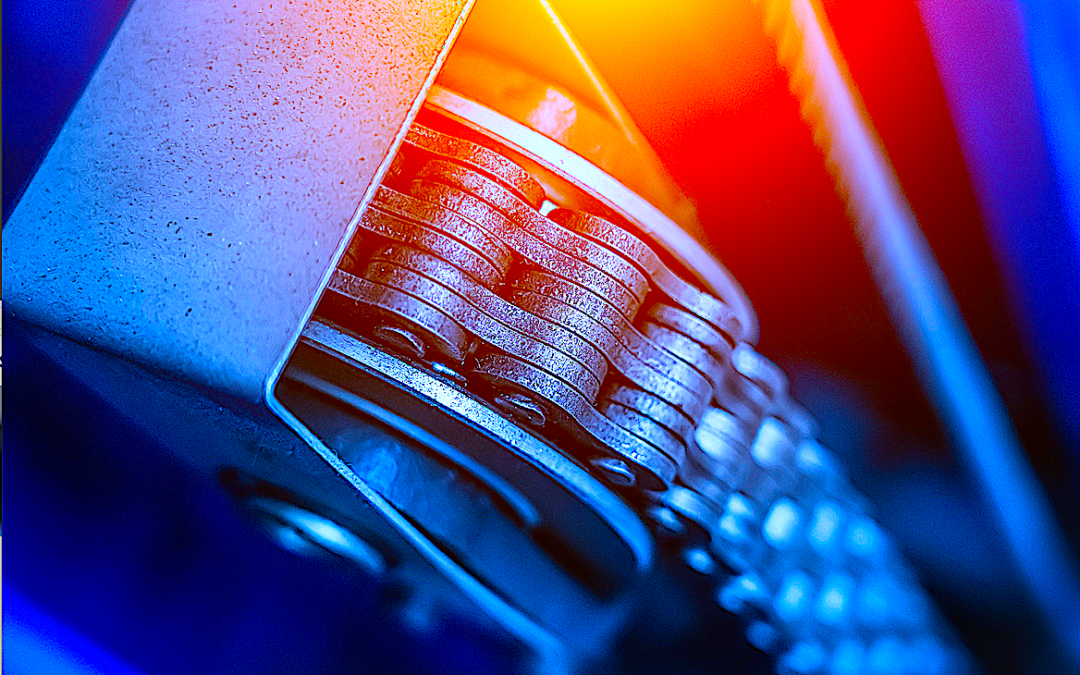

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 20, 2020 | Lubrication Corner, RAM Tools & Methods

All bearings are destined to eventually fail. While ineffective lubrication practices are, arguably, the greatest contributing factor in such failures, the root cause(s) are rarely investigated due to production and maintenance turnaround demands. It’s...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Nov 8, 2020 | Newsletter Column, RAM's Human Factor, Workforce Issues

In North America, the primary written language used in maintenance and asset management is English. Unfortunately, the English language tolerates the use of many imprecise words that can cast doubt on their intended meaning and lead to poor interpretation and results....