It’s too bad I cannot share all the details of a consulting experience that dates back a few years. Doing so is often thwarted by clients who first make a competent advisor sign a non-disclosure agreement and, occasionally, a non-defamation clause.

In this instance, I had spoken with a client whose facility had initially “saved” a few dollars by not using the right equipment protection. Managers had originally been advised to install oil mist in the storage yard as a hedge against potential storage duration lasting many months. But this recommendation was disregarded. Later, when it became clear plant construction had to be deferred for an indefinite time, the decision to ignore that previous recommendation backfired.

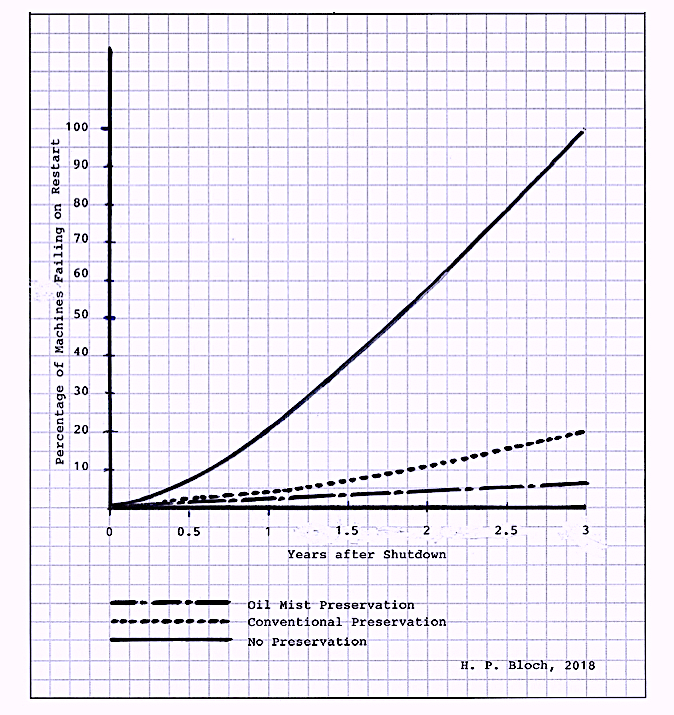

After about three years of unprotected outdoor storage, the numerous fluid machines in question were finally ready to be installed. By this point, though, the client had become justifiably concerned that many premature bearing failures would result and follow the trend curves of the author’s text Optimized Equipment Lubrication, Oil Mist Technology and Standby Preservation (see Fig. 1).

Fig. 1. Without preservation, expect 100% of bearings will show evidence of corrosion attack.

Fig. 1. Without preservation, expect 100% of bearings will show evidence of corrosion attack.

While it was now too late to take protective measures, the company again asked for advice. The managers didn’t like it when I began mapping out the types of prudent risk-reduction strategies that would minimize the number of post-commissioning operating interruptions.

My recommended strategies required dismantling a portion of the fluid machines that had sat in all kinds of weather for about three years. Retired machinists and mechanics were to be hired as inspectors and uncompromising supervisors. The total anticipated effort required this operation to spend more than two million dollars.

I believe that reliability professionals must aim for Best Available Technology. If they don’t see this as their role, they have no business calling themselves “Reliability Professionals.”

It’s clear that competent advisors are often brought in after the damage is done. All too often, however, the initialinvolvement is left to incompetent opinion-voicers. Of course, they’re held in much more esteem because they always support “the boss.” That is until the proverbial chickens come home to roost. . .TRR

Editor’s Note: Click Here To Download A Full List Of Heinz Bloch’s 24 Books

ABOUT THE AUTHOR

Heinz Bloch’s long professional career included assignments as Exxon Chemical’s Regional Machinery Specialist for the United States. A recognized subject-matter-expert on plant equipment and failure avoidance, he is the author of numerous books and articles, and continues to present at technical conferences around the world. Bloch holds B.S. and M.S. degrees in Mechanical Engineering and is an ASME Life Fellow. These days, he’s based near Houston, TX.

Tags: reliability, availability, maintenance, RAM, fluid machines, oil mist preservation, bearings, equipment storage