Honeywell, Houston, TX, has announced the release of its Immersive Field Simulator (IFS), an advanced industrial-training solution that incorporates 3D technology with operator-training simulation to create a collaborative learning environment for operators and technicians. The new, virtual-reality (VR) and mixed reality-based tool combines Honeywell’s Immersive Competency (IC) solutions with the company’s expertise in operator-training simulation (OTS).

HOW IT WORKS

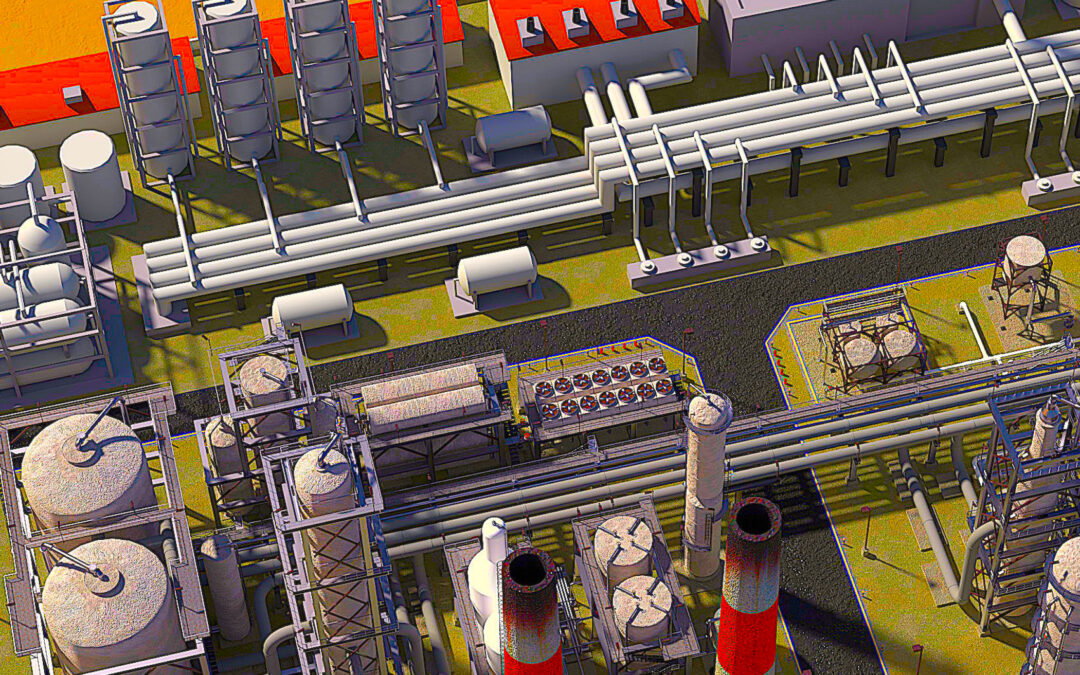

Providing a virtual replica of the physical plant integrated with a digital twin of the process, the IFS allows field and panel operators to practice and train together on different plant-operation and safety scenarios in a safe, simulated environment. According to the company, experience shows that students using VR technology can learn significantly faster than in a classroom.

With avatars representing virtual team members, the tool offers a smooth, virtual walkthrough to familiarize workers with the plant. The cloud-hosted, device-agnostic platform featuring flexible 3D models grows with the user as plant operations change. Customizable to meet specific instructional needs, the IFS lets project-team members and plant subject-matter experts easily create tailor-made training modules.

Honeywell notes that through the ability of the Immersive Field Simulator to enable “learning by doing,” the tool can help increase knowledge retention, minimize situations that result in operational downtime, and improve competencies across a variety of areas.

CLICK HERE to Learn More by Visiting Honeywell’s Competency Management Program