A manufacturing client recently asked me a seemingly difficult question: Does a simple, universal, inexpensive, easy-to-implement maintenance strategy that’s capable of substantially increasing machine reliability and availability actually exist? My answer wasn’t complicated: “Yes, and it’s existed since the advent of the industrial revolution: clean and lubricate.”

SOME BACKGROUND

Cleaning provides much more than an aesthetic appeal. A clean machine demonstrates to the world that operations and maintenance care for the asset. A regular cleaning regiment ensures that dirt cannot contaminate 1) the product, and 2) the bearing surfaces. In addition, much has been written about the benefits of working in a clean environment and the ease of performing maintenance troubleshooting and repair on a clean machine versus a dirty machine.

Lubrication is the lifeblood of a machine, without which, moving parts would fail in mere minutes. With elevated friction levels comes elevates energy requirements to overcome the friction. Simply put, when machinery employs sliding or rotating components it will require metered lubrication on a constant basis.

From new, a machine’s lubrication-delivery system can range from the most modest design incorporating simple zerk-style grease fittings at each bearing point to the infinitely more complex engineered, integrated, and automated lubricant-delivery system. Remarkably, the complexity or cost of the machine has no influence on the lubrication system design supplied by the original manufacturer. Engineered lubrication systems are most often offered by the OEM as a client option, most often allowing the decision to be client driven based on initial purchase price and not on life cycle costing.

The lubrication-system design (if one can call a grease nipple in a bearing a system a “design”) cited above represent the extremes in lubrication design and approach. Fortunately, from one extreme to the other and with all system designs in between, maintenance has the ability to tune lubrication-system setups to improve and optimize their lubrication approach. Depending on the design mechanics of the system, tuning adjustability can be found in three major places: the metering devices, the pump, and the pump-control system.

Metering Devices

If a machine has only zerk fittings at the actual bearing points, they can be easily upgraded to a metered system for very little cost. Lubrication-delivery lines are simply connected from each bearing point to a central engineered progressive divider block placed in an easy to access location. A grease gun is now locked on to a central zerk fitting on the block, and lubricant is pumped into the block until the meter pin cycles in and out indicating each point has received an exact metered amount. The system can be further upgraded with an automated pump, reservoir, and controller to provide lubricant-delivery consistency and flexibility. This can be actioned immediately or at a later date when funds permit.

Similar to progressive-divider metering devices, single-line meter and control units are nonadjustable. They depend on upfront engineering by the system supplier that is usually provided free of charge by the lubrication-system supplier prior to delivery to the machine builder or end user. Setup adjustability is performed through pump output calibration, pump actuation timing, and/or by performing a re-engineering of the metering piston discplacement size and replacement.

Systems that already employ adjustable metering devices, such as those found in single-line, positive displacement injector (PDI) systems (oil or grease); dual-line injector systems (oil or grease); or pump-to-point box-cam systems (oil only), allow plant personnel to change the amount of metered lubricant charge delivered to specified lubrication points. These system types are less expensive to design, as they require little or no initial design engineering, thereby placing the injector-calibration setup responsibility on the end user. Unfortunately, this can easily lead to over- or under-lubrication metering if the user isn’t familiar with the equipment or doesn’t understand how to calculate bearing-lubricant requirements. In addition, maintainers and machine operators can also blindly tinker with metering settings if they feel a bearing requires more or less lubricant—a situation that now moves from adjustability to “tamperability,” which can easily lead to over/under-lubrication and premature bearing failure.

Tuning these systems necessitates calculating the hourly bearing requirement and determining the minimum-to-maximum lubricant output shot per cycle for each injector size/type. The accumulated total amount of lubricant for all injectors is the amount that must be pumped through the delivery system every hour, and is the calculation amount used to set up the pump controller.

Making injector systems tamper-proof requires controlled access to the metering devices and can accomplished in numerous ways. The simplest control method requires the injectors to be grouped together and housed in a key-accessed lock-box allowing access to designated lubrication or reliability personnel.

Lubrication Pumps & Controls

Pumps come in many configurations and sizes and can be powered manually, electrically, or pneumatically. In each case, the pump’s delivery rate can be adjusted either on the pump itself, or through a pump controller.

In a simple, manual-grease system a grease-gun acts as the pump and metering device, while control is regulated by the grease-gun user and the scheduled preventive-maintenance (PM) instruction. If choosing to stay with this precarious approach, a degree of optimization and setup can be obtained. This requires a two-step process in which the grease-gun’s displacement must be determined to ascertain the number of shots required to meet the bearings’ calculated needs. After that’s been determined, the frequency of application must be controlled by the PM schedule. The number of grease gun shots or the PM schedule is used to fine tune any increase or decrease in the lubrication amount or frequency. This relies heavily on the maintenance scheduling consistency.

Automated lubricant-delivery systems are much more accurate, consistent, and easier to set up and control than manual systems. As a result, bearings run cooler (due to less friction), require less energy, and have as much as three times the service life of their manually lubricated counterparts. In short, return on investment from the relatively small purchase and implementation cost of an automated system is quickly realized.

Manual pumps are mechanically actuated with a lever arm connected to a positive displacement piston. The output delivery is adjusted by restricting the length of the piston stroke with an adjustment at the lever cam.

If reciprocating or rotary machine motion is available, the lever arm of the manual pump can be replaced with a power-takeoff pitman-arm linkage attached to the motion device. The shaft attachment point is offset from the center to produce a reciprocating (up and down) arm motion that produces a rocking motion at the pump shaft. This emulates the back-and-forth motion of the manual lever arm. By changing the length relationship of the pitman-arm attachment point and arm, the degree of arc will change and speed up or slow down the number of pump strokes per hour.

Pneumatically or electrically powered lubrication pumps are sized according to the system output requirement per hour. For effective lubrication, smaller amounts of lubricant, delivered on a frequent basis, e.g., every 10, 15, or 20 minutes, are preferable to a large amount that’s delivered hourly. This approach allows the designer to use a smaller, less expensive output pump. The pump, in turn, is connected to a controller that provides program adjustment through an on/off timer that actuates power to the pump giving the ability to adjust total delivery through the number of actuations or lubrication cycles per hour.

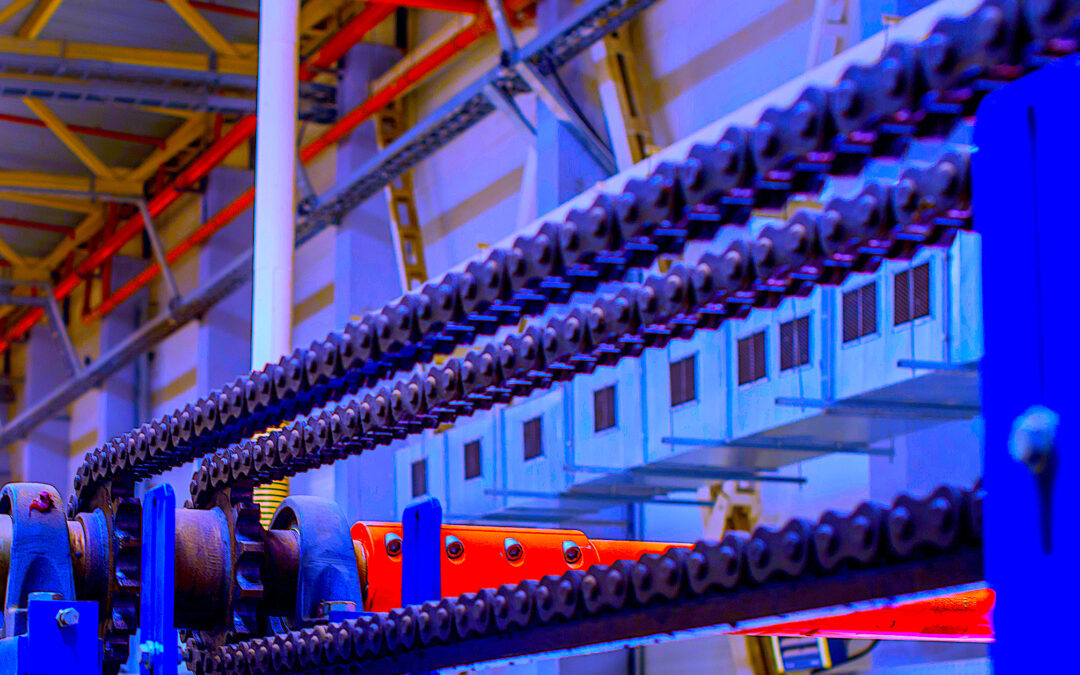

Pump-lubrication cycles can also be controlled in other ways, including with counters that calculate the number of machine or production operations, or by a condition signal, such as an amperage-draw meter that indicates an increase in energy draw from the machine system motor (due to a rise in mechanical friction that’s most often caused by lack of lubrication). This popular control mechanism is used in automotive-assembly plants to measure the amperage of conveyor-drive and take-up motors that activate and deactivate conveyor chain and pin lubricators.

MORE BEST PRACTICES

Regardless of its design, a lubrication-delivery system should be minimally evaluated on an annual basis to assess its effectiveness. Evaluations should include reviews of bearing-failure incidents, lubricant usage, changes in bearing running temperatures and energy draw, as well as checks for physical signs of over-lubrication and system neglect.

Spending a little time cleaning your machinery and getting to know and correctly set up your lubrication systems can deliver enormous gains in machine reliability, availability, life-cycle expectancy, and energy efficiency. With those benefits in mind, consider this question: Can you afford to ignore your lubrication systems? The answer, much like the one in the opening paragraph, isn’t complicated: “No, you can’t.“TRR

ABOUT THE AUTHOR

Ken Bannister has 40+ years of experience in the RAM industry. For the past 30, he’s been a Managing Partner and Principal Asset Management Consultant with Engtech industries Inc., where he has specialized in helping clients implement best-practice asset-management programs worldwide. A founding member and past director of the Plant Engineering and Maintenance Association of Canada, he is the author of several books, including three on lubrication, one on predictive maintenance, and one on energy reduction strategies, and is currently writing one on planning and scheduling. Contact him directly at 519-469-9173 or kbannister@theramreview.com.

Tags: reliability, availability, maintenance, RAM, maintenance management, lubrication, lubricants, metering devices, lubrication pumps, pump controls, lubrication delivery systems