A number of products have come out of the National Institutes of Standards and Technology (NIST) Department of Commerce project on Manufacturing Machinery Maintenance. Among them is a set of software tools that provide the ability to benchmark. For this article we’ll explore the “NIST Manufacturing Cost Guide,” which is the benchmarking software tool developed as part of the Manufacturing Cost Project.

This “Manufacturing Cost Guide” tool was discussed during an interview with NIST program manager Douglas Thomas, in the Nov. 19, 2020, installment of The RAM Review Podcast. In fact, that software is presently available by clicking on this link: Software Tools | NIST. It’s meant to be a tool for estimating costs in the U.S. manufacturing industry and related supply chain (Fig. 1).

Fig. 1. Front end for NIST’s “The Manufacturing Cost Guide” software tool built in Excel.

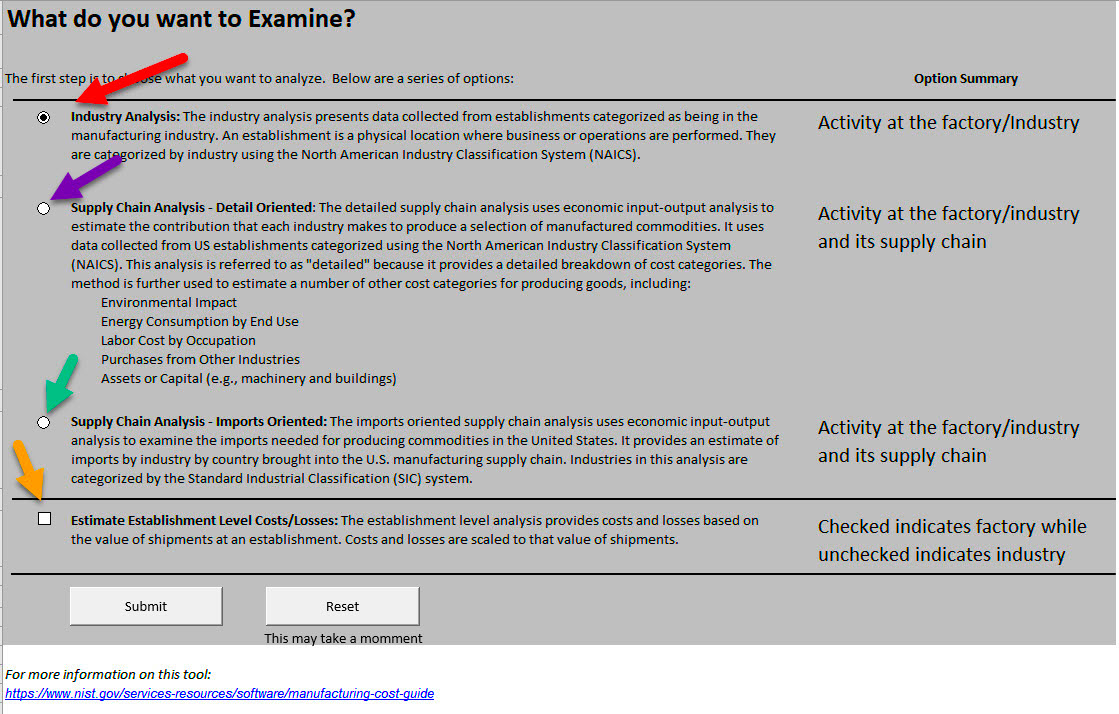

The tool extends well beyond maintenance costs and looks at industry averages for discrete manufacturing based upon all industries to individual industries and by value of product shipped. The data ranges from manufacturing, environmental impact, energy costs, labor costs, capital asset costs, cybersecurity losses, defect losses, and maintenance impact by type of maintenance (Fig. 2).

Fig. 2. Benchmarking details by industry, supply chain, imported supply chain and costs/losses.

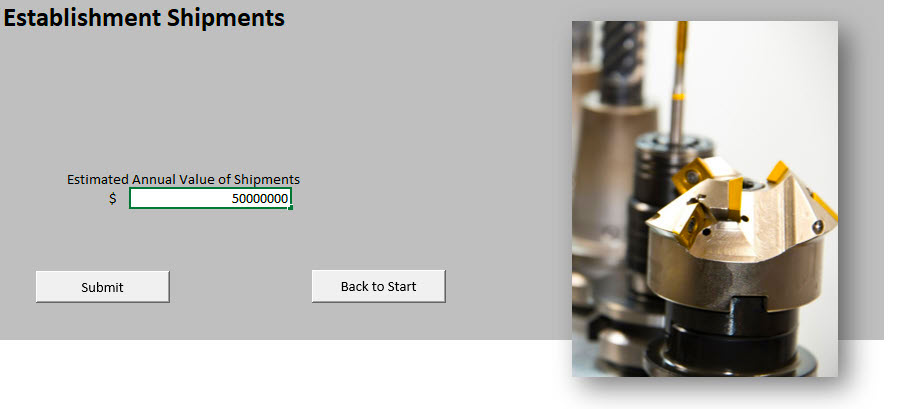

Following the selection of the type of study, in this case an industry analysis, we then identify the estimated annual value of shipments (Fig. 3) to look at companies of similar sizes. This provides the ability to benchmark against the same and other industries in the same size range.

Fig. 3. Setting a size range based on the annual value of shipments to look at industries of similar size.

Fig. 3. Setting a size range based on the annual value of shipments to look at industries of similar size.

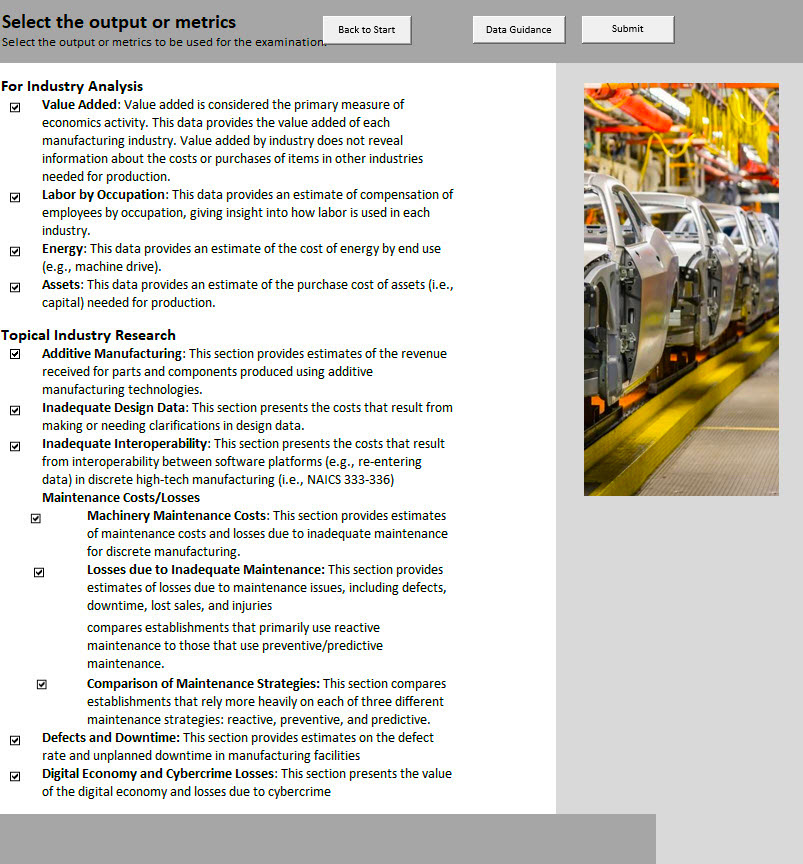

Once we have either performed this, or skipped it to look at the entire database, we can then select the output or metrics associated with a certain industry (Fig. 4). This allows us to narrow the benchmark review that we are performing. For instance, if we just wanted to look at maintenance costs and losses, we would select the check boxes in that subset.

Fig. 4. The output/metrics selection screen for data specific to the benchmark or research you are performing

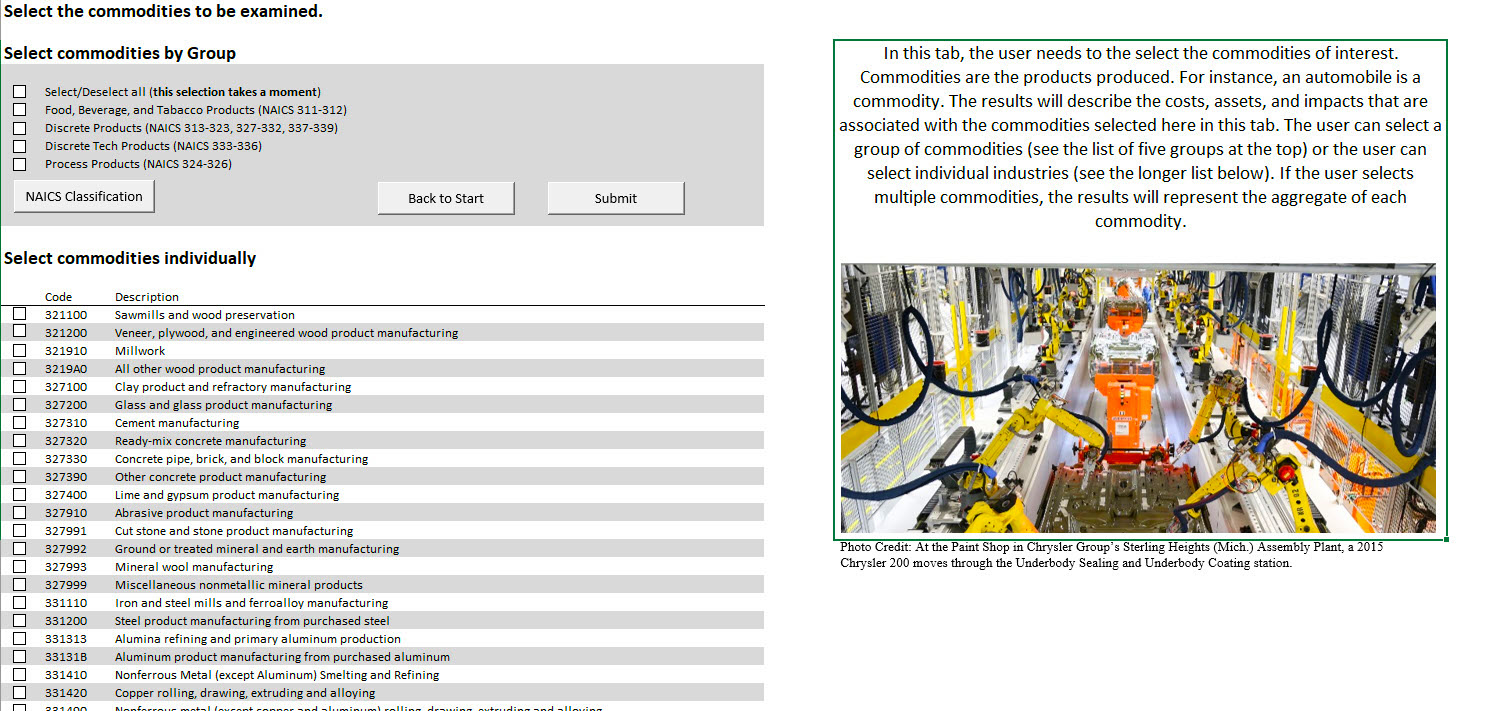

Following the metrics selection, we can select the industry, or industries, we are interested in reviewing (Fig. 5). In this example, we are going to use NAICS 327310, cement manufacturing, for our review.

Fig. 5. Industry selection for analysis by NAICS.

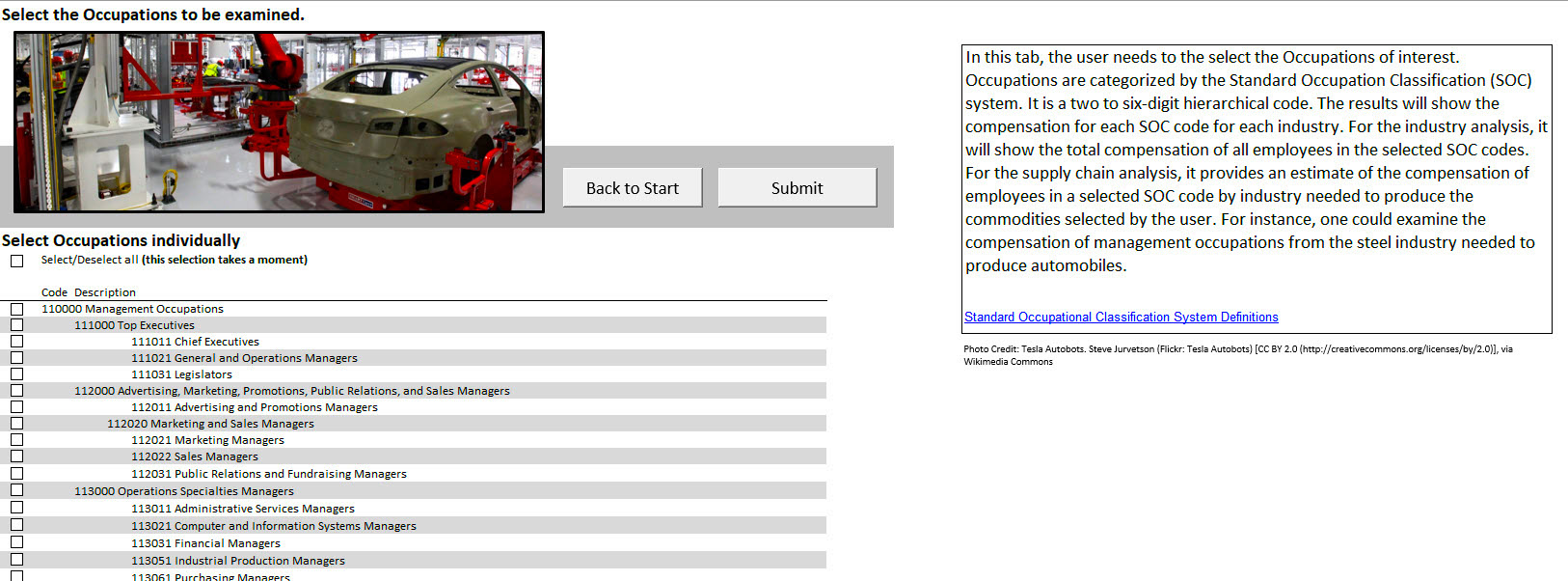

We are also then able to select personnel costs associated with the industry(s) we are interested in studying or benchmarking (Fig. 6). This provides the salaries and totals by occupation associated with companies of the size we are interested in.

Fig. 6. Selection of occupations to be examined.

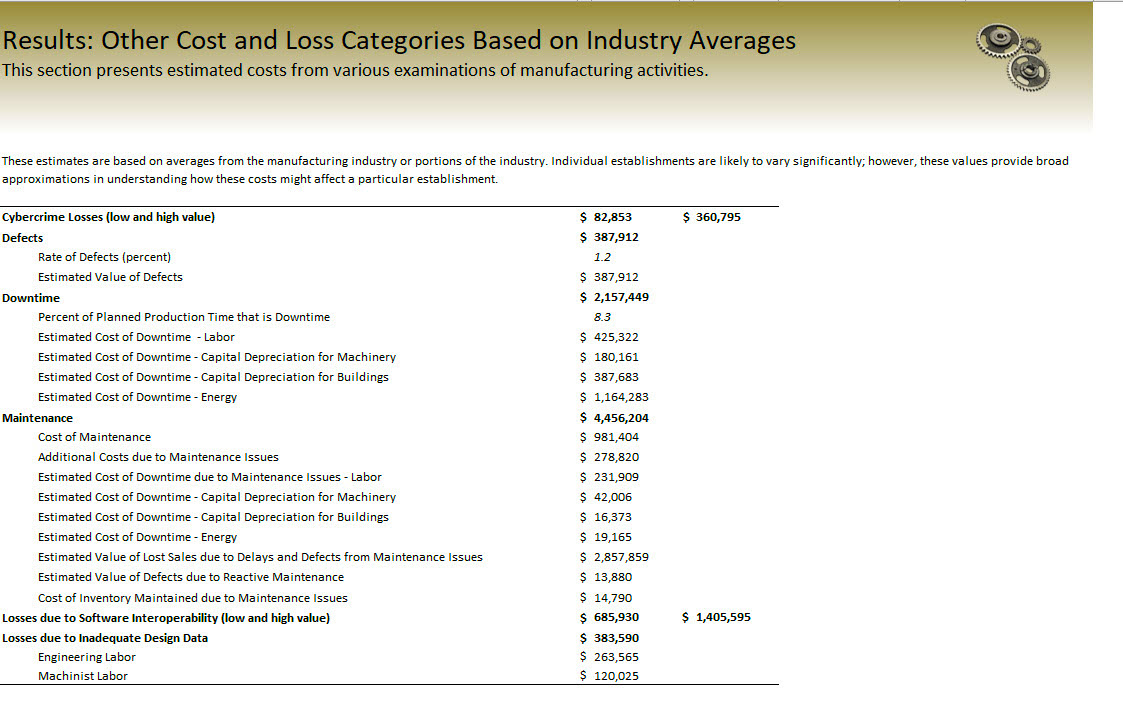

This, in turn, produces the results from the database for our benchmark study. These results can include “other costs and losses” (Fig. 7), as well as additional tabs that are available for review.

Fig. 7. Totals based on selections surrounding a $50M USD cement facility.

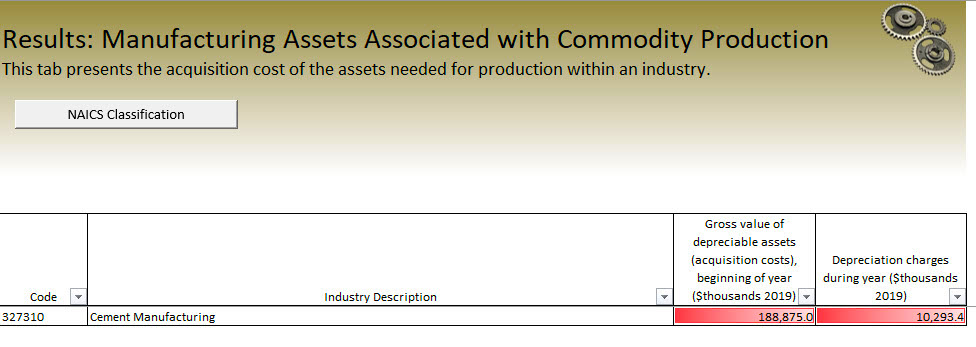

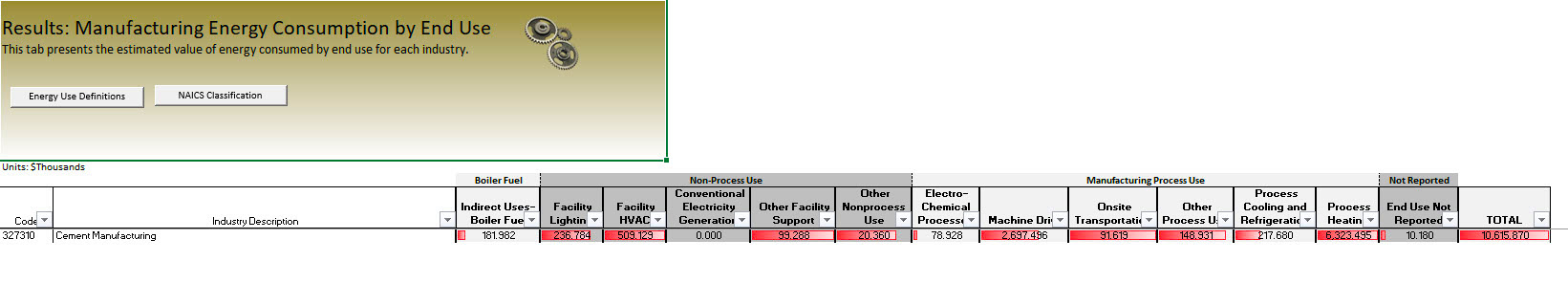

The values from Fig. 7 are further broken down in tabs. With asset costs, there is some detail, as shown in Fig. 8, and energy costs, as shown in Fig. 9.

Fig. 8. Value of physical production equipment assets.

Fig. 9. Energy costs associated with cement manufacturing.

There are detailed instructions on the use of this software tool in “The Manufacturing Cost Guide: A Primer – Version 1.0,” which can be found by clicking here: The Manufacturing Cost Guide: A Primer – Version 1.0 | NIST

Note that the overall manufacturing project is still in progress with, the upcoming development of the “Cost Assessment Tools for Sustainability (CATS),” which is meant to compare capital investments in manufacturing in order to compare the investments including their environmental impact. All of these tools are available at no cost.

SMRP has been supporting this project in relation to the Advanced Maintenance program. Again, more details on the program and tools being developed are discussed in Nov. 19, 2020, installment of The RAM Review Podcast, and the related Nov. 22, 2020, article, “NIST’s Commitment to Manufacturing Reliability and Maintenance” (see links below).TRR

Click On The Following Links For:

“The Economics of Manufacturing Machinery Maintenance, with NIST’s Doug Thomas”

(Nov. 19, 2020, Installment of The RAM Review Podcast)

“NIST’s Commitment to Manufacturing Reliability and Maintenance”

(Nov. 22, 2020 Article)

ABOUT THE AUTHOR

Howard Penrose, Ph.D., CMRP, is Founder and President of Motor Doc LLC, Lombard, IL and, among other things, a Past Chair of the Society for Reliability and Maintenance Professionals, Atlanta (smrp.org). Email him at howard@motordoc.com, or info@motordoc.com, and/or visit motordoc.com.

Tags: reliability, availability, maintenance, RAM, National Institute of Standards and Technology, NIST