Reliability suffers whenever best-available technology is not being used. Motivated engineers are well aware of this; they will learn, disseminate, and teach facts. Facts enable these professionals to add value during their entire lives. However, as they continually update their knowledge base, they, no doubt, will experience a measure of opposition from peers whose energy output is misdirected, to put it mildly. Pump lubrication deficiencies are often denied, and the type of outstanding reliability performance that oil mist offers is vastly underreported and often mis-stated.

Editor’s Note:

This article is based on a chapter in the author’s book

“Optimized Equipment Lubrication, 2nd Edition, 2021;”

De Gruyter, Berlin/Boston, (ISBN 978-3-11-074934-2).

Additional chapters will be highlighted on this website in the future.

Beginning with 1950 and learning from aerospace activities, reliability engineers focused on industrial lubrication technology and studied the merits of synthetic lubricants. Without these synthesized hydrocarbons, aerospace endeavors would have moved at a snail’s pace. From around 1960 through 1970, motivated reliability professionals began to familiarize themselves with the many different lubricant application methods found in process pumps. These professionals quickly learned that all manufacturers of rolling element bearings give ranking numbers to different lubricant applications. Then, like today, bearing manufacturers were unanimous in calling a jet of oil sprayed into bearings the most effective way of lubricating rolling element bearings. Oil mist (atomized oil droplets suspended and conveyed in very clean carrier air) is ranked a close second. However, there is a wide gap in the rankings between oil mist and the much lower ranked oil rings.

REVISITING ‘DN’

Many equipment manufacturers have expressed shock when told that they provided an oil ring for dn (rolling element center-to-center opposite each other in mm times shaft rpm) in process pumps whose dn is as high as 1,100,000, although research by Wilcock and Booser led to the stipulation that dn = 500,000 is the allowable limit. Nevertheless, oil rings are still widely used because they are inexpensive. To the wise, mere popularity rankings are as bad an indicator of reliability as lollipops are testimonials to good nutrition.

We wrote earlier that oil rings are a handicap for process pumps. For oil rings to function properly, they must be the right weight and have the right diameter. The shaft must be perfectly horizontal; the oil ring must be concentric within 0.002′′ (0.05 mm); it must remain immersed in the oil a certain predetermined amount, and the oil must remain within a certain predetermined viscosity range. Reasonable variations are allowed, although excessive deviations from one or more seemingly borderline but apparently “done this before” tolerances can be quite risky. If they happen at the same time, they will become the proverbial straw that broke the camel’s back.

Pressurized lubricant, e.g., oil jet or oil spray, is needed for the best possible lubrication of process pumps, but it would be offered only by the brightest manufacturers of process pumps. With a few notable exceptions, the use of external oil pumps to pressurize and then spray lube oil into bearings is clearly uneconomical. However, the development and provision of a small oil pump internal to the bearing housing of a process pump is entirely feasible. Taking its cues from modern automobiles, a small pump could be located in or on the housing; it would be driven from the main pump shaft. The small pump would take flooded suction from the oil in the sump and force the oil through spray nozzles into the bearings.

REGARDING VENDOR RESPONSE

Years ago, we tried to get vendors to understand that a confluence of all these requirements is rare. A highly skilled workforce would be needed and carrying out the proper installation and maintenance steps would require training, supervision, and compensation rarely found in the twenty-first century.

After a suitable presentation was made to a process pump manufacturer, its engineering staff studied the matter and advised they could easily design and accommodate a bearing housing-internal oil feed pump. The process pump manufacturer realized that such a pump would closely duplicate the oil pumps used in hundreds of millions of automobiles. Such pumps are commonly driven by skewed gears at a few hundred rpm and, as the owners of modern cars well know, rarely fail. However, the process-pump manufacturer realized that these small oil pumps would represent prior art, which makes them ineligible for patent protection. Fearful of others copying the design, the pump manufacturer decided not to market such products.

This does not mean, however, that a reliability-focused user must continue to put up with oil rings that have simply been tweaked from their previously flat cross-section to some newly advocated, trapezoidal cross-section. Although oil rings made by combining high performance plastics (HPPs) with carbon fiber composites are considered more abrasion-resistant than those made of copper-containing metals, they are not the panacea. As mentioned several times throughout the book from which this excerpt is taken (see above), it is time to implement reliable solutions rather than tweak 19th Century technologies.

HPP oil rings merely address one or more of the symptoms of the oil ring issue. They are not removing the underlying root causes of bearing life reductions that can have their origins in flawed oil rings. Among such underlying root causes we might find oil rings running downhill and contacting bearing housing interiors, oil rings that are not concentric to begin with, oil rings that have not been stress relieved by annealing (heat stabilization) and lose concentricity in operation, oil rings that are too light, too heavy, too deeply immersed in oil, immersed not deep enough in oil, immersed in oils of an incorrect viscosity or an untold combination of possible deviations.

Experience-based rankings of different lube applications have also been brought to the reader’s attention in the text from which this excerpt is taken, and oil rings fared average, at best. Regrettably, nobody has data on how many oil rings will malfunction because a maintenance person did not properly install the shaft system; or the pump design allows the oil ring to slosh around; or the pump manufacturer supplied oil rings that were flawed for one or more reasons.

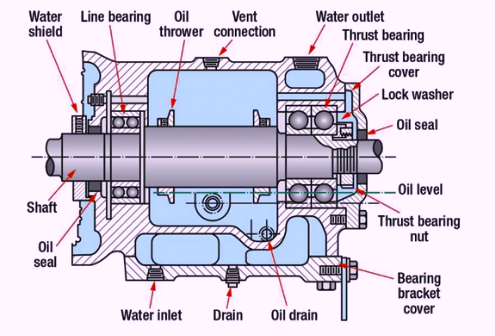

The last thing a pump manufacturer would want its users to know is how many black oil incidents are caused by designs that overlook the need to provide an escape path for small amounts of oil trapped behind bearings, or for not seeing to it that there is pressure equalization between the space to the left and right of any particular rolling element bearing (Fig. 1). For grease-lubricated bearings, keep in mind that every grease-lubricated rolling element electric motor bearing would run cooler, longer, and safer on pure oil mist.

Fig. 1. Balance holes allow equalization of pressures on both sides

Fig. 1. Balance holes allow equalization of pressures on both sides

of each bearing and the central part of the housing.

(Source: Worthington Pump; circa 1960.)

Consider the example of an oil mist-lubricated electric motor commissioned in 1978: It was reportedly still running in a Texas plant in 2008. The owners claimed that no maintenance or changing of parts had been done in 30 years and an estimated 130,000 operating hours. Many moderately loaded ball bearings had L-10 catalog ratings (90% of the bearings not showing defect indications) of 500,000 and 600,000 h. Therefore, 30 years with standstill protection and vibration-free operation on pure oil mist met expectations.

WHY PUMP USERS SHOULD REQUEST LUBE-DELIVERY UPGRADES

Factory tests are valuable and should be welcomed. Factory engineers and managers will agree that the machines on a pump manufacturer’s test stand are properly aligned, and the lubricant is fresh and clean. In contrast, the degree of inaccuracy encountered in many field environments differs greatly from the accuracy found on test stands. Neither the training nor the abilities of crafts and service personnel will measure up to expectations all the time.

In some installations, the piping connected to the pumps is pushing and pulling. As a result, housings deflect or yield, and bearings are edge loaded. The most elementary of equations explains what happens when a force of, say, 10 lbs. acts on an original contact area of one hundredth of one square inch. Force per unit area equals psi, thus 10/0.01 = 1,000 psi, which is easily carried by an oil film. However, housing deflection may cause the bearing to contact the edge of the raceway, so, let’s say only one thousandth of 1 square inch represents the area now contacted. If that were the case, the pressure would be 10/0.001 = 10,000 psi and metal-to-metal contact would probably result. The pressure would be far too high; the oil film would be interrupted and would no longer provide adequate separation of parts.

Shaft alignment is often achieved by putting shims under the equipment’s feet which, as a logical consequence, tends to cause shaft systems to be at a slight angle relative to the true horizon. On shipboard, pumps pitch and roll. Equipment surveillance and precautionary oil changes differ on ships from what is found at many land-based installations. These and other experience factors interact; they admittedly shape and skew rankings in the eyes of individuals with field experience. Their backgrounds and perceptions differ, so it is up to pump users to judge where to place their trust. We have observed that many process pumps in industry often experience repeat failures.

No reasonable person believes that one needs to show data to prove that driving cars with worn tires is a greater risk than driving on tires with tread. Also, what looks worn to one person, looks normal to another. It is no different with oil rings in pumps at location X versus location Y.

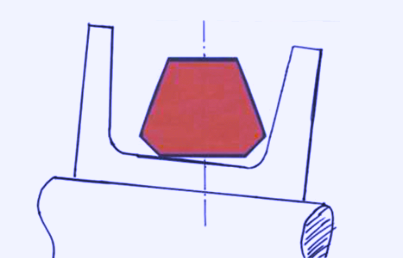

Fig. 2. Loose oil ring running in a ring carrier.

(Source: Simon Bradshaw, Proceedings of the

17th Texas A&M University International Pump Users Symposium, Houston, TX, 2000.)

The ultimate ramifications of a trapezoidal oil ring operating in this manner can be foreseen: A trapezoidal oil ring has two pointed or circumferential ridges, one on the left side and one on the right. Pointed ridges have a very small total surface area. As the oil ring slews from side to side in its carrier sleeve, it touches the side of the carrier sleeve. This means the force per unit area, the pounds per square inch (commonly known as pressure) will be rather high. When that happens, the pointed ridge will break through the oil film and abrasion will occur.

Whenever a pointed ridge breaks through the oil film, there is increased friction, and the oil ring slows down. Long-term satisfactory operation is at risk unless the pump owners invest heavily in preventive maintenance action. But preventive maintenance costs money, and that is simply an additional reason why oil rings rank average to low on the pump-lube-application ranking table.

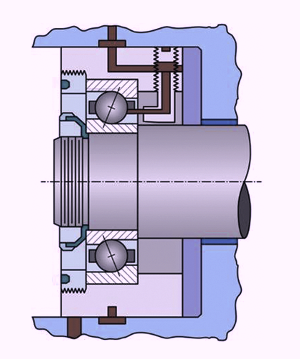

Again, jet-oil lubrication represents the highest rated application method. Also called oil-air, (see Fig. 3), jet-oil lubrication has been widely used in aerospace since 1949. It can open a window of opportunity for reliability-focused users and/or innovative pump manufacturers. Think of a small oil pump, either internal to the process pump bearing housing or incorporated in a small assembly screwed into the bottom drain of a process pump. This upgrade can provide filtration, metered flow, and proper pressure downstream of the oil sump and upstream of the spray nozzles. Motivated users have written this preferred lube application approach into their pump specifications and are actively pursuing this pump reliability enhancement.

Fig. 3. Jet oil lubrication, whereby liquid oil is sprayed (and directed)

Fig. 3. Jet oil lubrication, whereby liquid oil is sprayed (and directed)

into the rolling elements of a bearing.

Having examined process pumps that come with reliability compromises, it is only fair to state that things do not have to be that way. More to the point: Whatever style oil rings users presently have in their pumps are probably not the most reliable components.

Fig. 4. Relating pump repair events and fire incidents.

More dependable means of applying lubricants to bearings are either available or have been designed. Intelligent upgrading would reduce maintenance labor and improve the safety and reliability of many plants. The recipients of better pumps would suffer fewer pump fires ( Fig. 3) and would operate more safely, consistently, and profitably.TRR

Editor’s Note: Click Here To Download A Full List Of Heinz Bloch’s 24 Books

ABOUT THE AUTHOR

Heinz Bloch’s long professional career included assignments as Exxon Chemical’s Regional Machinery Specialist for the United States. A recognized subject-matter-expert on plant equipment and failure avoidance, he is the author of numerous books and articles, and continues to present at technical conferences around the world. Bloch holds B.S. and M.S. degrees in Mechanical Engineering and is an ASME Life Fellow. These days, he’s based near Houston, TX.

Tags: reliability, availability, maintenance, RAM, process, pumps, bearings, lubrication, lubricants