“Think Local, Act Global” is a phrase typically attributed to Patrick Geedes, an early 20th-century urban planner in Scotland. Geedes’ thinking seems quite applicable to the overall global climate-change challenge and, by extension, in today’s RAM arena. As I’ve often written, energy management in the manufacturing and process industries offers an excellent opportunity to create a big impact without requiring substantial lifestyle changes for the population at large. Moreover, by virtue of their respective roles and responsibilities, today’s RAM professionals can be key players in this endeavor. The first part of this multi-part article provides a brief overview of what’s at stake and where operations can achieve the greatest return from their improvement efforts.

CONSIDER THE NUMBERS

Approximately 35% of the end-use and 32% of the total energy consumed in the United States powers industrial operations (U.S. EIA, 2019). According to the U.S. Department of Energy (DOE), the consumption of energy by the industrial sector is inherently inefficient (refer to multiple DOE industry sector reports in References).

For example, the bulk-chemistry industry, which consumes 29% of the total energy consumed by industrial operations, could reduce energy consumption by 23.77% simply by applying currently industrial best practices (U.S. Department of Energy, 2015a). The same DOE report suggested that with R&D focused on energy efficiency, consumption could be reduced to a practical minimum of 61.67%! To put that in perspective, the total energy consumption in the United States is about 100 quads (quadrillion btu), which equates to a little more than 29 million MWh.

The chemical industry alone utilizes about 2.7 million MWh per year. Reducing energy consumption to current industry best practice in the chemical industry alone would reduce energy consumption by over 6o0,000 MWh. That’s about 2.2% of the total energy consumed in the United States.

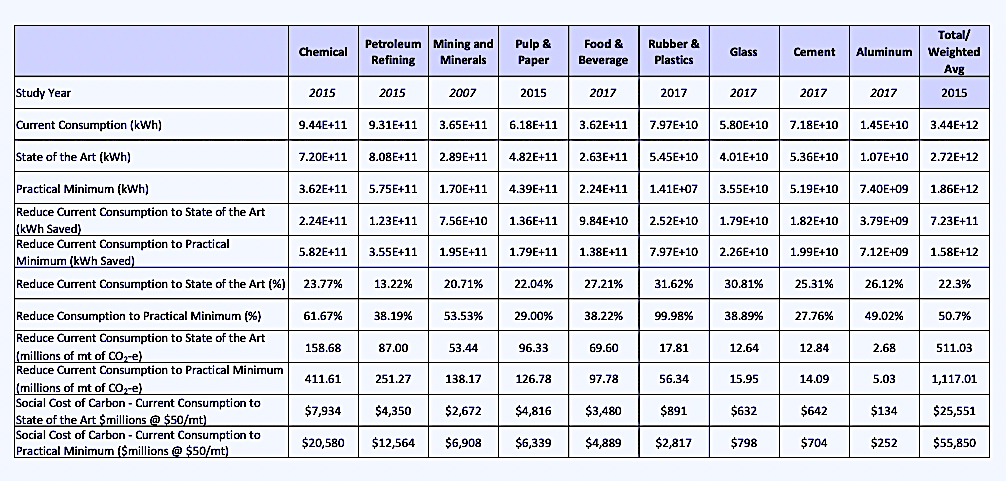

The bulk-chemistry industry, though, is just one opportunity. The magnitude of the opportunity to reduce industrial energy consumption is similar in other industries (Table I).

Combined, the DOE reports on industrial energy consumption suggest that with investment, the industrial consumption of energy could be practically cut in half. In round numbers, doing so would reduce total energy consumption and associated greenhouse gas emissions in the USA by about 16%. According to the U.S. Energy Information Administration (U.S. EIA, 2020), energy-related carbon emissions for 2019 totaled 5.13 billion mt of CO2-e.

Table I. Industry-by-industry potential to reduce energy consumption in select heavy industries.

Table I. Industry-by-industry potential to reduce energy consumption in select heavy industries.

Assuming the accuracy of the DOE data, industry accounts for about 1.65 billion of the total energy-related CO2-e emissions. Adopting current state of the art energy management best practices, emissions could be reduced by about 368 million mt CO2-e. Implementing the practices required to achieve the practical minimum energy consumption would reduce CO2-e emissions by over 800 million mt. That, in itself, is an amazing prospect.

The estimated range for the social cost of carbon (SCC) is all over the board. However, many estimates tend to hover around the $50 – $75 per mt. Assuming a middle value of $62 per mt, reducing industrial CO2-e emissions to current state of the art best practice energy management levels in the United States alone would be worth about $23 billion per year in avoided SCC. Achieving the practical lower-limit industrial-energy-management levels would equate to about $50 billion of avoided SCC in the USA.

THE STARTING POINT

The types of improvements described above begin by reducing parasitic frictional losses in mechanical systems. They can be enormous energy hogs.

Mechanical systems convert and transfer energy to accomplish work. There are many types of these systems components. Electric motors convert electrical energy into rotating mechanical energy. Internal combustion engines convert chemical energy into rotating mechanical energy. Gear reducers create a mechanical advantage while gear increasers create a speed advantage. Couplings and belt-drives transfer energy via mechanical linkages while hydraulic and pneumatic systems transfer energy via fluid power mechanisms. The objective with a mechanical drive system is to convert energy and transfer it to accomplish work such as crushing, pumping, conveying, blowing, etc., as efficiently as possible.

The field of tribology is defined as “the science and engineering of interacting surfaces in relative motion. It includes the principles of friction, wear and lubrication. Nonproductive parasitic frictional losses in industrial equipment consume about 7.5% of the total industrial energy consumption (Jost, 1966; Jost & Schoefield, 1981). That figure represents about one-third of the total industrial energy losses that the DOE estimated could be recovered by deploying existing industry best practices for energy management as described in Table I.

COMING UP

The idea of reducing cost and decreasing the environmental impact of a manufacturing or process plant by focusing on management of parasitic frictional losses is a very compelling one. And our ability to do so is very real.

In Part II of this article (next week), I’ll provide details on the tactics for moving from theory to practice in the quest to improve profits and reduce the environmental footprint in our plants and facilities.TRR

REFERENCES USED IN PART I:

Jost, H.P., (1966). “Lubrication (Tribology) – A report on the present position and industry’s needs.” Dept. of Education and Science. London, UK: H. M. Stationery Office.

Jost, H. P. & Schoefield, J. (1981). “Energy Saving through Tribology: A Techno-Economic Review.” Proceedings – Institution of Mechanical Engineers, 195(1), 151-173.

U.S. Energy Information Administration (2019). U.S. energy facts explained. https://www.eia.gov/energyexplained/us-energy-facts/. Accessed 07 Dec. 2020.

U.S. Energy Information Administration (2020). U.S. Energy-Related Carbon Dioxide Emissions, 2019.

U.S. Energy-Related Carbon Dioxide Emissions, 2019 (eia.gov).

U.S. Dept. of Energy (2005). Energy Tips – Pumping Systems: Reduce Pumping Costs through Optimum Pipe Sizing. Pumping Systems Tip Sheet #9, October. Reduce Pumping Costs through Optimum Pipe Sizing: Industrial Technologies Program (ITP) Energy Tips – Pumping Systems Tip Sheet #9 (Fact Sheet). Accessed 11 Dec. 2020.

U.S. Dept. of Energy (2007). Mining Industry Energy Bandwidth Study. Industrial Technologies Program. https://www.energy.gov/sites/prod/files/2013/11/f4/mining_bandwidth.pdf. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017a). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Advanced High Strength Steels (AHSS) Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-advanced-high-strength-steel-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017b). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Aluminum Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-aluminum-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017c). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Cement Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-cement-manufacturing. Accessed 05 December 2020.

U.S. Dept. of Energy. (2015a). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Chemical Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-chemical-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017d). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Food and Beverage Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-food-and-beverage-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017e). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Glass Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-glass-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2015b). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Petroleum Refining. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-petroleum-refining. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2017f). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Plastics and Rubber Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-plastics-and-rubber-manufacturing. Accessed 05 Dec. 2020.

U.S. Dept. of Energy. (2015c). Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Pulp and Paper Manufacturing. Office of Energy Efficiency & Renewable Energy. https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-pulp-and-paper-manufacturing. Accessed 05 Dec. 2020.

ABOUT THE AUTHOR

Drew Troyer has 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 250 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees, and is Master’s degree candidate in Environmental Sustainability at Harvard University. Contact him directly at 512-800-6031 or dtroyer@theramreview.com.

Tags: reliability, availability, maintenance, RAM, climate change, energy efficiency, tribology, mechanical systems