The concept of stress vs. strength “interference” is important in the field of reliability engineering. This concept is so simple that one could almost call it naïve. However, minimizing interference between stress and strength in the plant often results in a clash between the two asset-management titans: operations and maintenance. Let’s explore this clash and discuss strategies to achieve harmony and reliability in the plant.

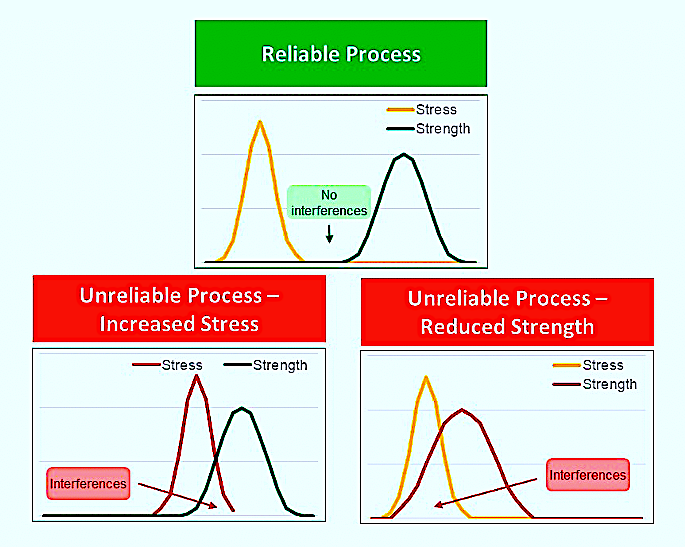

Stress vs. strength interference refers to the strength of an asset that is a function of its design and the degree to which it’s well maintained, relative to the stress placed on the asset from an operational-demand perspective (see the figure below). If the distribution of asset or process strength over time exceeds the distribution of operational stress, the two tails of the distributions don’t interfere with one another and the process is reliable.

But what happens if the strength of the asset is compromised due to poor design, poor parts and materials selection or quality, poor installation, and/or insufficient or ineffective maintenance performed on the asset? The distribution of strength is flattened and/or shifts to the left and interferes with the distribution of applied stress. Translation: Asset or process reliability is compromised. Conversely, if the design, material selection and quality, installation, and maintenance are robust and up to par, but the asset is operated incorrectly or beyond its design limits, the applied stress curve flattens and/or shifts to the right and interferes with the asset’s strength distribution. This would also indicate that asset or process reliability is compromised.

Management of stress vs. strength interference requires cooperation between plant operations and maintenance.

IT’S A MATTER OF COOPERATION

Stress-vs.-strength-interference curves provide an excellent backdrop for discussing the importance of cooperation between the operations and maintenance functions in the plant. As an asset-management consultant, coach, mentor, counselor and, sometimes, arbitrator to many clients, I’ve observed too many instances where attempts to explain poor asset-reliability performance in plants devolve into ugly episodes of the blame game. A better approach is to conduct a peer assist exercise.

A peer assist is an event where two or more people or groups that really need to cooperate due to mutual codependences, will engage in active listening and communication. The purpose is to help both parties, who may view each other as adversaries, gain a better understanding about the challenges, trials, and tribulations they face.

In a nutshell, a peer assist works like this: I know what I know in my context of the world—you actively listen to me and truly seek to understand me and my challenges. You know what you know in your context of the world—I actively listen to you and truly seek to understand you and your challenges. We discover that we share some (often many) of the same views, but we didn’t know it until we actively listened to one another. You gain a better understanding about why I make certain decisions that previously made little or no sense to you, and I reciprocate. Now we’re prepared to engage in and informed and honest dialogue to create value that neither of us could create on our own.

In the plant, a peer assist centered around the issues of stress vs. strength interference is extremely productive. It can help break the stalemate of perceptions that “operations doesn’t care about the assets,” and that “maintenance doesn’t care whether we make money or not.” (I know this is an oversimplification of the frequent conflicts that occur between the two functional groups.) The peer assist opens communications and shines light on the realities of the situation.

TIME ZONES CAN BE YOUR ENEMY

One of the challenges you’ll likely encounter in a peer-assist discussion aimed at improving the overall performance of your assets is the time desynchrony that exists between causes and effects. For example, let’s say we’re a few hundred tons short on our production goals this month and operations decides to turn the dial to 11 to make up some ground. There’s a good chance that action won’t affect asset reliability this month. The increased stress, though, will likely cause damage that adversely affects future reliability. Similarly, if maintenance is deferred or executed with a lack of precision or a focus on proactive control, the machine in question probably won’t fail this month. The damage will affect future reliability.

Note that we present the stress-vs.-strength curves as a two-dimensional concept model, with asset or process strength and stress on the X-axis and magnitude on the Y-axis. In reality, there is a Z-axis, which represents time that must be accounted for when forecasting asset or process reliability, or when analyzing those event where that reliability has been compromised.

Over time, operational abuses accumulate and cause the applied stress curve to slowly flatten and shift to the right. Meanwhile, maintenance deficiencies accumulate to cause the strength curve to flatten and shift to the left. This puts the assets and the processes that they support on a perilous trajectory toward stress vs. strength interference and asset and process failure. When this occurs, don’t get trapped in the operations vs. maintenance blame game.

IN THE END

Upper-percentile asset managers recognize that failure is the combined effect of operational overreach and maintenance deficiencies, and that it’s a cumulative process that occurs over time. The challenge is to minimize stress vs. strength interference related to the confluence of operational and maintenance stresses that, over time, weaken the strength of the asset or the process.

Utilize the concept of stress vs. strength interference as a backdrop to conduct a cross-functional peer assist, and actively engage and listen across functional lines in the plant and organization. First understand, then seek to be understood. By doing so, you’ll be ready to work cooperatively toward real solutions that achieve your shared goals for asset and process reliability and performance.TRR

ABOUT THE AUTHOR

Drew Troyer has 30 years of experience in the RAM arena. Currently a Principal with T.A. Cook Consultants, he was a Co-founder and former CEO of Noria Corporation. A trusted advisor to a global blue chip client base, this industry veteran has authored or co-authored more than 250 books, chapters, course books, articles, and technical papers and is popular keynote and technical speaker at conferences around the world. Drew is a Certified Reliability Engineer (CRE), Certified Maintenance & Reliability Professional (CMRP), holds B.S. and M.B.A. degrees, and is Master’s degree candidate in Environmental Sustainability at Harvard University. Contact him directly at 512-800-6031 or [email protected].

Tags: reliability, availability, maintenance, RAM, operational demand, peer assist, communications, workforce issues