ABB, Zurich, Switzerland, has launched ABB Ability Liquid Routing Library, a control-engineering inventory for food and beverage manufacturers and those in other liquid related industries, including tank farms, pharmaceuticals, and chemical-resin plants.

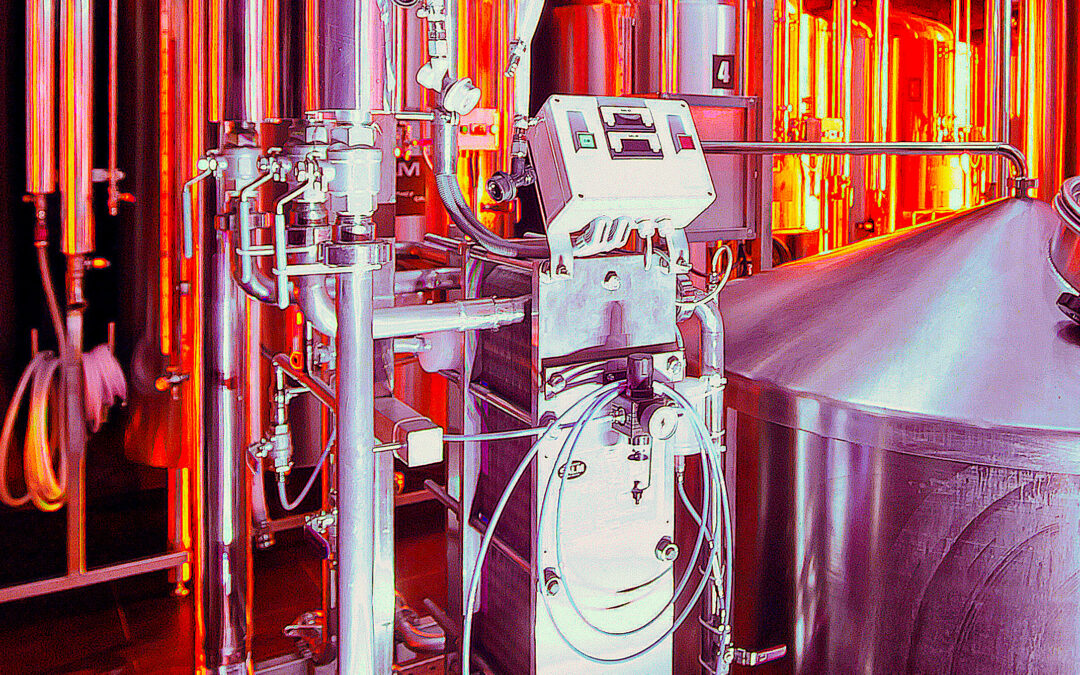

The digital application draws on the ABB Ability System 800xA, one of the most powerful Distributed Control System (DCS) automation platforms available, and will support routing and cleaning in place (CIP) functionalities needed for liquid-led production. It can be used wherever products are transported, stored or processed in tanks and lines, and is said to be particularly relevant to dairy, brewing, sugar, mills, and edible-oil application programming.

Ready-made objects including libraries, typicals, and templates for product routing, with recipe-based CIP, track and trace, preventive plant maintenance, Excel-based bulk data tools are made available for customers through the library.

Functionalities include alarm handling, alarm propagation between different units, queue handling for online production changes, control and supervision of process objects, interlocks, and transfer of product and equipment settings such as product codes, unit names, and unit states.

According to ABB, use of the Liquid Routing Library provides efficient commissioning and maintenance due to its transparency, granularity, and diagnostics. The application creates a streamlined environment for reliable control via a dynamic, easy-to-use interface that gives operators access to the whole plant and different layers of information, which is said to capable of improving c operator effectiveness by as much as 25%.