When a maintenance-work request reaches the desk of the planner, his or her first action item is to review the request and determine the priority of the work. This determination will influence whether the planner takes immediate action (Emergency Response) or queues the work request for appropriate attention based on a formal or informal priority system.

The decision process to determine work priority will vary greatly from one organization to another. Whereas some operations allow the requestor to provide a preliminary prioritization, many will place that preliminary determination at a help-desk level (if a help-desk exists). Ultimately, final work prioritization is the direct responsibility of the planner, whose determination will influence how that work is planned, scheduled, and performed, in accordance with a pre-determined maintenance workflow response. The more information a work request contains, the easier and faster it is for the planner to make a work-priority decision (see the article “Make Work Orders Work: The Request” below).

Click Here To Read Ken Bannister’s Aug. 15, 2020, Article

“Make Work Orders Work: The Request”

In many organizations, requestors almost always rate their work requests higher than the appropriate maintenance response. (That approach is especially prevalent where there’s lack of clarity surrounding the priority-decision process, or a lack of trust due to a traditionally vague and non-inclusive type of maintenance response). A help-desk that might be assisting the requestor could then make a different priority determination, i.e., upgrade or downgrade the priority based on a different understanding of the work requirement or decision process. Moreover, when the work request reaches the planner, the priority could change yet again. All of this creates a broken decision chain that only serves to confuse the client/stakeholder the maintenance department serves.

IMPORTANCE OF A PRIORITY DECISION MATRIX

When clear work priority classification, decision, and workflow processes are in place and followed, they provide a solid foundation on which a maintenance client/stakeholder service-level agreement (SLA) can be built and observed. With a working SLA in place, client/stakeholders no longer feel the need to prioritize their request, instead placing their trust in the planning-and-scheduling-priority process.

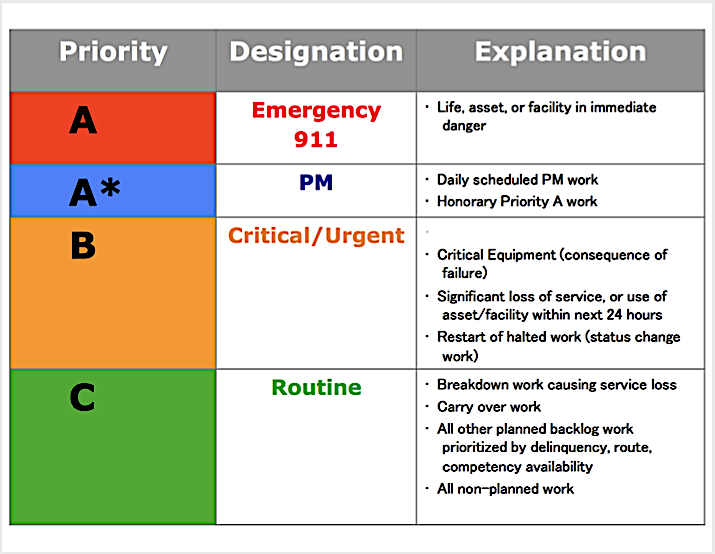

The problem with most priority systems is they are overcomplicated and confusing. The worst case I’ve observed featured more than 30 priority levels from which to choose. That meant significant time and effort would be spent on deciding, say, if a priority should be at level 21 or 23. Best-practice operations reduce such confusion by keeping their priority decision to less than five levels. I like to work with a simple, but highly effective, four-level decision matrix depicted in Fig. 1. In this type of matrix, priority can be traffic-light colored (Red/Amber/Green (RAG) and/or ABC/123 rated.

Fig. 1. A simple, 4-level work-priority decision matrix

(Courtesy EngTech Industries, Inc.)

♦ Priority A. This level is reserved solely for Emergency work, that allows work to be performed with or without a work order for life-threatening, asset-threatening, or building-threatening situations. Work is fast-tracked, which allows it to immediately break in the schedule (sometimes called “break-in” work). Think of this situation as a 911-type emergency. Over the period of a work year, only a handful of these types of emergencies should be encountered

♦ Priority A+. From a scheduling perspective, the PM program takes considerable effort to set up, schedule and perform. If PM does not happen quickly and consistently, asset life-cycle will suffer, and premature failure is assured. As the PM system is the heart of the asset-management system and a primary life-cycle strategy, all PM work should be assigned an “honorary” Priority A. I like to distinguish this as an “A+” or “1+” priority rating, which ensures the work is considered as the highest daily priority on the schedule, unless bumped by Emergency work.

♦ Priority B. This level is reserved for Critical/Urgent work defined by work being performed on critical designated assets, or if the planner determines that a significant loss of service can be expected within 24 hours if the maintenance work is not performed. This priority level is also applied to “carry-over” work, i.e., work that was not completed during the previous day or shift.

♦ Priority C. This level is used for all other scheduled and non-scheduled work. Scheduling of such work will depend on geography, asset access, parts availability, and resources availability, and be based on how the planning and scheduling group manages its backlog. (This topic will be discussed in an upcoming article for The RAM Review.)

THE NEXT STEP

Appropriate workflows for each priority need to mapped out, added to the service level agreement, and placed in the hands of all maintainers, help desk, and client stakeholders.TRR

ABOUT THE AUTHOR

Ken Bannister has 40+ years of experience in the RAM industry. For the past 30, he’s been a Managing Partner and Principal Asset Management Consultant with Engtech Industries Inc., where he has specialized in helping clients implement best-practice asset-management programs worldwide. A founding member and past director of the Plant Engineering and Maintenance Association of Canada, he is the author of several books, including three on lubrication, one on predictive maintenance, and one on energy reduction strategies, and is currently writing one on planning and scheduling. Contact him directly at 519-469-9173 or kbannister@theramreview.com.

Tags: reliability, maintenance, availability, RAM, work management, work order, work priority, maintenance workflow, asset management, planning and scheduling