The maintenance work order (MWO) is, unequivocally, the most important tool in the maintenance department. Unfortunately, many maintenance shops look upon work orders as nuisance items that take time to produce and complete. As a result, work orders are often reduced to skeletal documents containing poor work instruction (often a simple replication of the work request), no job-time estimate, and little or no collected job completion data regarding time taken to complete the work, machine-failure findings, parts used, etc. All of those elements, however, are relevant (and crucial) in ensuring first-time quality repair, building and reporting on maintenance history, and understanding machine failure.

The MWO is the pivotal document around which any paper-based or computerized Asset Management System (AMS) software is built. When implementing a maintenance or asset-management program, all roads lead to and from the work order (WO). A maintenance work order is made up of two distinct components: 1) the Instructional component, and 2) the data-collection component. These components are generally populated in two distinct phases, either at the formulation phase of the work order by the planning and scheduling group, or at the work completion phase by the tradespersons, planners, and persons entering completion data into the asset management system (AMS). Note: The individual entering that data can be a trade, a planner, fa oreperson, or a member of the clerical staff.

The Instructional Component is primarily completed by the planning group (planner) responsible for the delivery of concise and objective work instruction to the foreperson or scheduler to schedule the work based on priority and location, and to the tradesperson(s) or contractor(s) based on work to be performed and the order of work, and, finally, to the MRO-inventory department or purchasing department to pre-purchase/kit assemble all known parts and/or specialty tools required to complete the work.

Upon work completion, tradesperson(s), forepersons, or contractors are responsible for documenting detailed instructions and relevant photographic evidence of failure and work completion to the planning group for any supplementary work requirements resulting from the initial job, or additional unrelated “new found” work requirements.

The Data-Collection Component of the work order is primarily used for reporting purposes to establish performance, service level delivery, maintenance program effectiveness and to more accurately predict and pre-empt future failure events.

Certain fields on the work order can be instructional to the WO user AND also be used for data-collection purposes. The following breakdown of the work order identifies all likely fields to be found on the general information section of the work order, or within a work package compiled in an AMS. At the end of each field description, the field is identified as instructional, data collection, or both.

WORK-ORDER BREAKDOWN: GENERAL INFORMATION SECTION

The work order is closely related to its pre-curser-companion work document, the maintenance work request (MWR) used to receive, understand, accept, and document the “ask,” or request for maintenance work to be performed on behalf of the maintenance client or stakeholder. For further description of this first-stage MWR document, see The RAM Review article, “Maintenance Work Orders: The Request” (April 10, 2020). In most maintenance organizations, the planning group initiates the work order using the information collected on the MWR. If the information is incomplete or unclear, it is up to the planner to clarify the information with the client or stakeholder prior to initiating a work order in the system.

Once the work order is initiated, most AMS software programs will automatically transfer the request information into the request section of the MWO usually located at the very top of the work order. This section is made up of the following fields:

Maintenance Work Order #: This is a unique identification number (UIN) used for database search purposes to find and recall the open or closed work order. This number is automatically assigned by the AMS software (instructional).

Maintenance Work Request #: This is a linked field identifying the original MWR # used to initiate and populate the MWO. This field is used for database search purposes to find and recall the original MWR document when required (Instructional).

Work-Order Trigger: Not all work orders are triggered by a MWR, e.g., they can be triggered by a machine SCADA signal, system-alarm signal, oil-analysis report, vibration-analysis report, maintenance report, investigative-type work order (see WO type field), PM work order (see WO Type field), etc. This field is used for database-search purposes to report on the effectiveness of alarm systems, PdM and PM programs, and to determine how work is identified throughout the plant or organization (Data Collection)

Work Order Creation Date and Time: This is a simple date and time stamp. Once the AMS creates and assigns a new work-order number, a clock is automatically started within the software and it used as a baseline time-stamp to calculate the Mean Time To Response (how long it takes the planning department to respond to a bona fide work request), calculate the Mean Time To Schedule the work, and calculate the Mean Time To Repair (time from the initial request to the completed repair). These reports are used to back up any service-level agreements between maintenance and its stakeholder/clients and assess the response efficiency of the maintenance group. (Instructional and Data Collection)

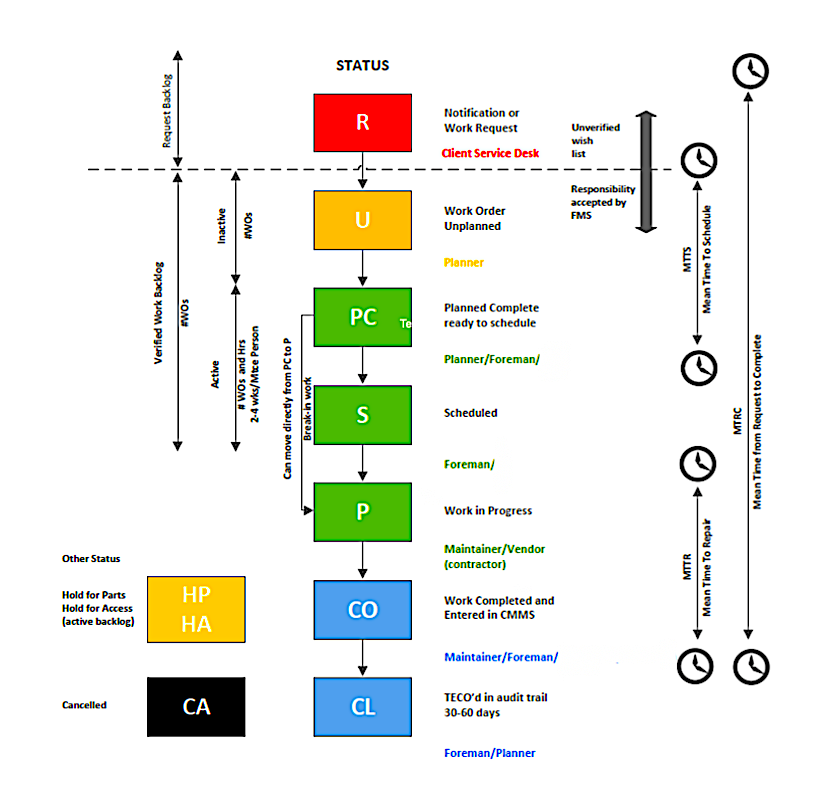

Work Order Status: Before a work order can be released to scheduling and placed on the backlog, it requires a substantial amount of planning and preparation work. Now that the work request has been accepted, the work order will now go through a series of workflow stages in which its status will change within the AMS software. As the status changes, the WO is again date- and time-stamped by the software allowing the maintenance department to performance monitor the work process, the current backlog loading, and report back to the client on the status of their work. Figure 1 shows a typical flow for an SAP asset-management system work order.

Fig. 1. A typical work-order-status workflow

(Copyright EngTech Industries. Inc.)

Requestor Name: This identifies the original individual who requested work to be performed. It’s also used to identify the contact person should further explanation regarding the MWR be required, and, finally, used by the maintainer or contractor to advise on the start and completion of work at the job site. Note: This data can also be used for work prioritization when certain requestors have priority over others for work scheduling. (Instructional and Data Collection)

Requestor #: This usually is a phone number or extension that can be used to contact the work requestor as needed. (Instructional and Data Collection)

Contact Name and #: This is used when the requestor is a surrogate or the on-site contact is different from the original requestor. (Instructional and Data Collection)

Request Department/Client/Stakeholder Group: This is used to identify the client or stakeholder group represented by the requestor. This data field is used as a primary search field for reporting purposes to identify and sort maintenance work performed for a specific department, client or stakeholder group e.g. production department, finishing line, purchasing department, etc. Note: This data can also be used for work prioritization when one department or group has priority over others for work scheduling. (Instructional and Data Collection)

Problem Location: Most physical assets are fixed and can be geographically or physically located within a building. If, however, a business has many assets, or similar assets located across many locations, it can be difficult for a planner to estimate travel time without knowing the exact location of the problem, or for a maintainer/contractor to easily locate the problem asset and begin work in a timely manner. The Problem Location field can refer to site, building, floor, area, room for facility assets; by production line or suite for manufacturing assets; or by GPS locate for linear assets. Maintenance history and costs by location can also be tracked using the searchable data in this field. (Instructional and Data Collection)

Asset #: In an asset-management system, all data pivots around the asset. Once work and associated data are linked against an asset number, a concise work and cost history can be managed, trended, analyzed, and reported on. When maintaining facilities, rooms, floors, buildings, and sites can be pseudo-managed as fixed assets to capture work at an asset level and, thus, more easily understand what, how, and where work has taken place, e.g., dry-walling or electrical repair performed in a specific room can be captured at the room level (the room is treated as an asset), which can then be set up as a child of a floor to allow roll-up cost accounting. Similarly, a floor can be treated as an asset to capture work performed in corridors or open spaces not associated with any room, which can, in turn, be set up as a child of the building, etc. The asset # is a unique identification number and should always be prominently labeled or displayed on the asset to ensure the work is being performed on the correct equipment. (Instructional and Data Collection)

Asset Sub-System Location: For large equipment pieces or a production-line system with only one asset # identified, it is often helpful to identify machine sections by name, system, or process to assist the maintainer in locating the repair location on the machine. e.g., on a large paper-making machine, it could be the fourdrinier table, the dryer section, the calendar section, or machine-lubrication system. This can also be a searchable field for work- and cost-reporting purposes, if needed. (Instructional)

Work Type: This is a search field used to identify the primary required work discipline category to be performed, as well as correctly allocate the appropriate trade group(s) to manage the work and complete the work order, and report on the work discipline and allocation (internal or contract), which will lead to a better understanding of staffing levels and costs per primary trade discipline. Work type is typically broken down into Electrical (Machine/Building/Vehicle), Electronic Machine/Building/Vehicle), Mechanical (Machine/Vehicle), Structural (Building), Plumbing (Machine/Building), HVAC (Building/Vehicle), Carpentry (Building), Instrumentation (Machine/Building/Vehicle). (Instructional and Data Collection)

Work Order Type: This search field is used to track the classification of the work order to determine how much work is proactive versus reactive in nature. The classification is also used to prioritize work (especially in the case of an emergency-work- order type). For a full explanation of this important subject see The RAM Review article “Understanding, Classifying and Tracking Work” (June 5, .2020). (Instructional and Data Collection)

Operational Impact: This field identifies the impact on the operations or client and helps the planner and scheduler to prioritize work accordingly, e.g., does the impact of work, require downtime, slow-down, or have no effect on operations? All work coded as such can be sorted and compiled to provide gross reporting on service-level agreements and asset availability. (Instructional and Data Collection)

Safety Impact: This is a simple “yes” or “no” field that tracks how much work is initially assessed as an emergency, wherein the building, equipment, or human life is thought to be in danger. The Safety Impact field sets up an immediate priority for scheduling work. (Instructional and Data Collection)

COMING UP

Once the above information has been inserted in the appropriate fields, the first section of the work order is complete. At this point, the planner can move on to the job-plan section of the work order or package, The job-plan section will be covered in an upcoming article.TRR

Editor’s Note: Click The Following Links To Read Ken Bannister’s Planning & Scheduling Articles:

“Maintenance Work Orders: The Request” (April 10, 2020)

“Understanding, Classifying, and Tracking Work” (June 5, 2020)

ABOUT THE AUTHOR

Ken Bannister has 40+ years of experience in the RAM industry. For the past 30, he’s been a Managing Partner and Principal Asset Management Consultant with Engtech industries Inc., where he has specialized in helping clients implement best-practice asset-management programs worldwide. A founding member and past director of the Plant Engineering and Maintenance Association of Canada, he is the author of several books, including three on lubrication, one on predictive maintenance, and one on energy reduction strategies, and is currently writing one on planning and scheduling. Contact him directly at 519-469-9173 or kbannister@theramreview.com.

Tags: reliability, maintenance, availability, RAM, asset management systems, CMMS, work management, work order, maintenance work order, data collection, maintenance report, maintenance workflow