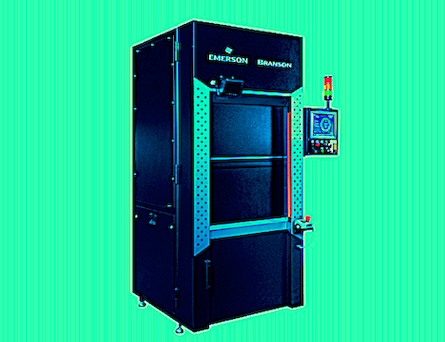

Emerson has launched the Branson GL-300, a new laser-welder platform that provides greater production capability for high-mix and batch manufacturers of plastic components without compromising product quality or performance. The company describes the GL-300 as a highly flexible, quasi-simultaneous plastic joining solution, designed to deliver efficient high-quality welds in a wide range of applications and help manufacturers to increase production efficiency.

According to Emerson, manufacturers are increasingly in need of machines and processes that can be quickly and cost-effectively adapted to changing production demands and specifications. For low-volume, high mix manufacturers especially, flexible welding solutions that allow faster production startup, provide a critical advantage. The Branson GL platform is said to meet this need by combining highly efficient and accurate welds with cost-effective and easy-to-change tooling that enables faster set-up and adjustment for changing product specifications.

Manufacturing capability is further enhanced by a range of unique features including a high-quality scanning system, easy-to-use HMI, large (300mm x 300mm) weld area, multiple weld modes, variable spot size as low as 0.5 mm and an adjustable laser power source height. These enable the Branson GL-300 to support applications with different materials, application sizes, and production speeds.