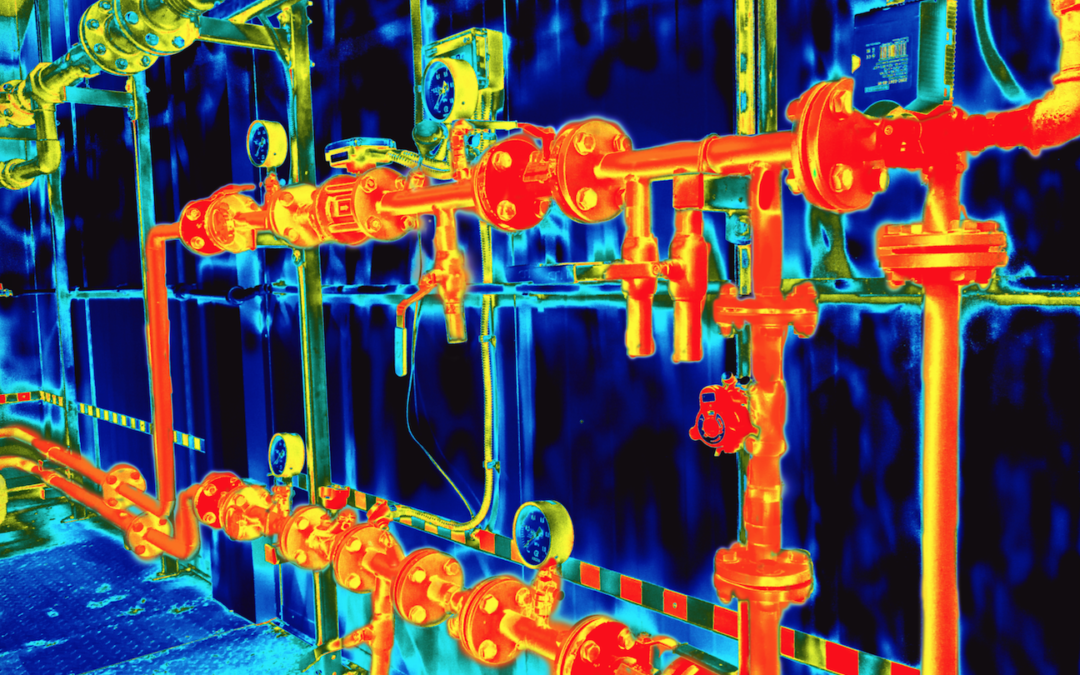

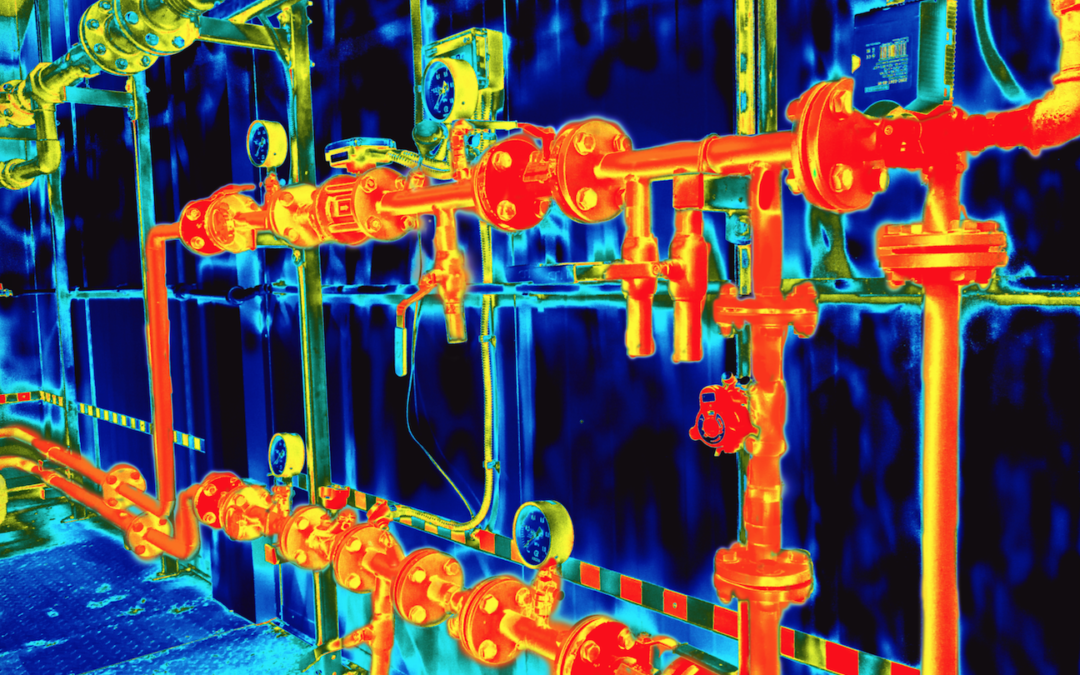

by Jim Seffrin, CMRP | Oct 31, 2019 | IR Thermography, RAM Tools & Methods

Infrared (IR) inspections are now routine for many facilities. By proactively addressing incipient or latent failures detected during a single inspection, costs associated with unscheduled downtime and damage to electrical and mechanical equipment can be avoided....

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Oct 25, 2019 | Plant Reliability in Dollars and $ense, RAM Tools & Methods

Despite various negative opinions swirling through the plant-engineering community, Weibull analysis can, in fact, improve decision-making at a site. The value of this tool in terms of RAM (reliability, availability, maintenance) can’t be overstated. In short, Weibull...

by Heinz Bloch, P.E., Editor | Oct 25, 2019 | RAM Tools & Methods, The Bloch Files, Workforce Issues

You probably have long suspected this: Some companies can be their own worst enemies. I offer the following examples, from my perspective as book author/technical writer, of how some companies earn a bad name, while others earn a good one (and good things that come...

by Drew Troyer, CRE, CMRP, T.A. Cook/Accenture, Editor | Oct 18, 2019 | Plant Reliability in Dollars and $ense, RAM Tools & Methods

Inspections are essential to any physical-asset-reliability-management initiative. Thus, the importance of monitoring Overall Inspection Effectiveness (OIE) within your operations can’t be overstated. As depicted in the following chart, OIE is the leading metric for...

by Heinz Bloch, P.E., Editor | Oct 18, 2019 | RAM Tools & Methods, The Bloch Files, Workforce Issues

One of the nicest bonuses that a retiree enjoys is freeness of speech. Here, I’m taking advantage of that “freeness” by sharing a few thoughts on good reliability managers and some of the ways they approach their roles (or should). Consider my points in the...

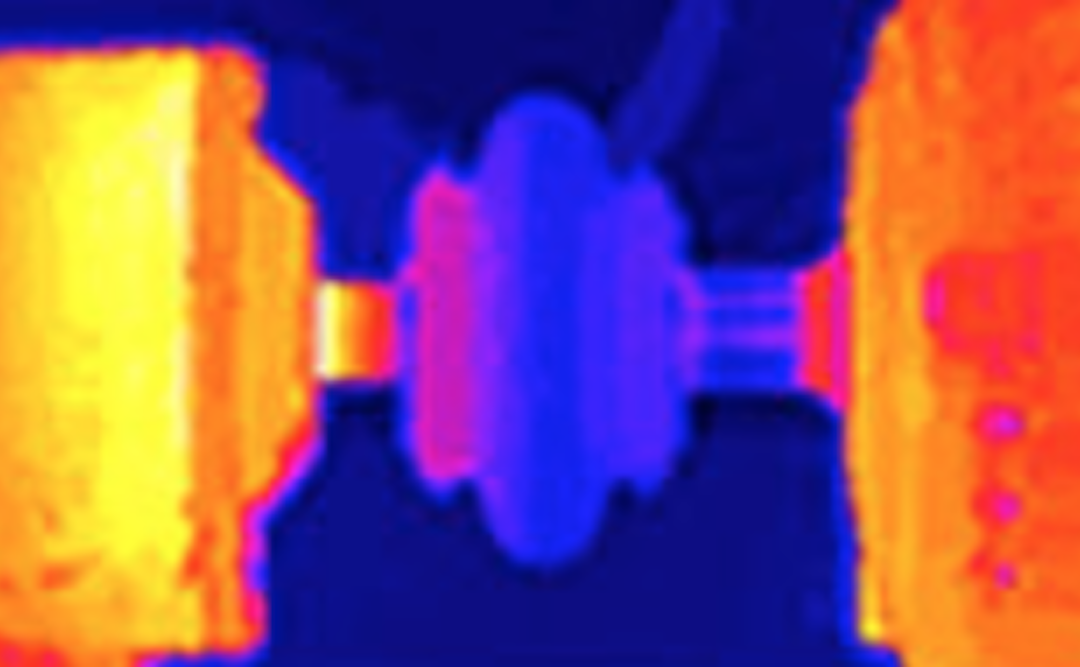

by Jim Seffrin, CMRP | Oct 18, 2019 | IR Thermography, RAM Tools & Methods

To everything there is a season. The same is true for infrared inspection routes within facilities where equipment or systems are operated seasonally. Traditionally, many facilities perform infrared inspections on an annual basis. While this approach may detect...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 11, 2019 | Lubrication Corner, RAM Tools & Methods

When it comes to harsh working environments, the resource sector reflects some of the most brutal. In light of such conditions and the typically remote locations of these operations, equipment reliability is paramount. Although this article focuses on the resource...

by Ken Bannister, MEch (UK), CMRP, MLE, Editor | Oct 6, 2019 | Planning & Scheduling, RAM Tools & Methods

Achieving recognition as a valued partner within a corporation is a “best practice” hallmark coveted by all aspiring maintenance organizations. Achieving this type of recognition is built on the cornerstone foundation that an effective Maintenance Planning and...

by Heinz Bloch, P.E., Editor | Oct 6, 2019 | Maintenance Management, RAM Tools & Methods, The Bloch Files

Few pieces of petrochemical process machinery lend themselves more readily to early symptom-cause identification than reciprocating compressors. This fact becomes quite clear when considering how the neglect of subtle performance changes can result in costly wrecks....